What is Global Industrial Conductive Flooring Market?

The Global Industrial Conductive Flooring Market is a specialized segment within the broader flooring industry, focusing on flooring solutions that are designed to conduct electricity. These floors are essential in environments where static electricity can cause damage to sensitive equipment or ignite flammable substances. Conductive flooring is commonly used in industries such as electronics, pharmaceuticals, and healthcare, where maintaining a controlled environment is crucial. The market for these specialized flooring solutions is driven by the increasing demand for safety and efficiency in industrial operations. As industries continue to evolve and adopt more advanced technologies, the need for conductive flooring is expected to grow. This market is characterized by a variety of materials and technologies, each offering different levels of conductivity and durability to meet the specific needs of different industries. The global reach of this market indicates its importance in supporting industrial activities worldwide, ensuring that operations can proceed safely and without interruption due to static-related issues.

Epoxy Flooring, Polyurethane Flooring, Others in the Global Industrial Conductive Flooring Market:

Epoxy flooring is a popular choice within the Global Industrial Conductive Flooring Market due to its durability and versatility. Epoxy is a thermosetting resin that, when applied as a coating, forms a hard, durable surface that is resistant to chemicals, abrasion, and impact. This makes it ideal for industrial environments where heavy machinery and equipment are used. In the context of conductive flooring, epoxy can be formulated to include conductive materials that help dissipate static electricity, making it suitable for use in electronics manufacturing facilities and other sensitive environments. Polyurethane flooring, on the other hand, offers a different set of advantages. It is known for its flexibility and resistance to thermal shock, which makes it ideal for environments where temperature fluctuations are common. Polyurethane can also be formulated to be conductive, providing a safe and effective solution for industries that require static control. Other types of conductive flooring materials include vinyl and rubber, each offering unique benefits. Vinyl flooring is often chosen for its ease of installation and maintenance, while rubber flooring is prized for its slip resistance and comfort underfoot. These materials can be engineered to meet specific conductivity requirements, ensuring that they provide the necessary level of static control for different applications. The choice of material often depends on the specific needs of the industry and the environment in which the flooring will be used. For example, in a cleanroom environment, where contamination control is critical, a seamless epoxy or polyurethane floor may be preferred due to its ability to be easily cleaned and maintained. In contrast, in an automotive manufacturing facility, where heavy equipment is used, a more robust material like rubber may be more appropriate. The Global Industrial Conductive Flooring Market is diverse, with a wide range of materials and technologies available to meet the needs of different industries. As technology continues to advance, new materials and formulations are being developed to provide even greater levels of conductivity and durability, ensuring that this market will continue to evolve and grow.

Medical, Electronic, Aerospace, Automotive, Others in the Global Industrial Conductive Flooring Market:

The usage of Global Industrial Conductive Flooring Market solutions spans several critical industries, each with unique requirements and challenges. In the medical field, conductive flooring is essential in environments such as operating rooms and laboratories, where static electricity can interfere with sensitive medical equipment and compromise patient safety. These floors help to maintain a controlled environment, ensuring that medical procedures can be carried out safely and effectively. In the electronics industry, conductive flooring is crucial in manufacturing facilities where static electricity can damage sensitive electronic components. By providing a path for static discharge, these floors help to protect valuable equipment and ensure the quality and reliability of electronic products. The aerospace industry also relies on conductive flooring to protect sensitive equipment and maintain safety standards. In environments where flammable materials are present, such as aircraft hangars and maintenance facilities, conductive flooring helps to prevent static-related incidents that could lead to fires or explosions. The automotive industry uses conductive flooring in manufacturing plants and assembly lines to protect electronic components and ensure the safety of workers. These floors help to prevent static buildup, which can cause damage to electronic systems and pose a risk to workers handling flammable materials. Other industries, such as pharmaceuticals and food processing, also benefit from conductive flooring solutions. In these environments, maintaining a controlled environment is critical to ensuring product quality and safety. Conductive flooring helps to prevent contamination and protect sensitive equipment, ensuring that operations can proceed smoothly and efficiently. Overall, the Global Industrial Conductive Flooring Market plays a vital role in supporting a wide range of industries, providing the necessary solutions to ensure safety, efficiency, and reliability in industrial operations.

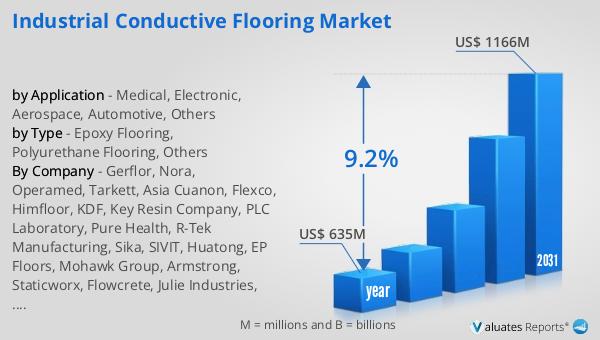

Global Industrial Conductive Flooring Market Outlook:

The global market for Industrial Conductive Flooring was valued at approximately $635 million in 2024, and it is anticipated to expand significantly, reaching an estimated $1,166 million by 2031. This growth represents a compound annual growth rate (CAGR) of 9.2% over the forecast period. This impressive growth trajectory underscores the increasing demand for conductive flooring solutions across various industries. As industries continue to evolve and adopt more advanced technologies, the need for effective static control measures becomes more critical. Conductive flooring provides a reliable solution to this challenge, offering a safe and efficient way to manage static electricity in industrial environments. The market's growth is driven by several factors, including the increasing complexity of industrial operations, the growing importance of safety and efficiency, and the need to protect sensitive equipment and products from static-related damage. As a result, the Global Industrial Conductive Flooring Market is expected to continue its upward trajectory, providing valuable solutions to industries worldwide. This growth reflects the market's ability to adapt to changing industry needs and its commitment to providing innovative and effective solutions for static control.

| Report Metric | Details |

| Report Name | Industrial Conductive Flooring Market |

| Accounted market size in year | US$ 635 million |

| Forecasted market size in 2031 | US$ 1166 million |

| CAGR | 9.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gerflor, Nora, Operamed, Tarkett, Asia Cuanon, Flexco, Himfloor, KDF, Key Resin Company, PLC Laboratory, Pure Health, R-Tek Manufacturing, Sika, SIVIT, Huatong, EP Floors, Mohawk Group, Armstrong, Staticworx, Flowcrete, Julie Industries, Altro, Ecotile, MERO, Formica, Silikal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |