What is Global MEMS Packaging Solder Market?

The Global MEMS Packaging Solder Market is a specialized segment within the broader electronics packaging industry, focusing on the materials and processes used to encapsulate and protect Micro-Electro-Mechanical Systems (MEMS) devices. MEMS are tiny integrated devices or systems that combine electrical and mechanical components, and they are used in a wide range of applications, from consumer electronics to automotive systems. The packaging of these devices is crucial as it ensures their functionality, reliability, and longevity. Solder materials play a vital role in this packaging process, providing the necessary electrical connections and mechanical support. The market for MEMS packaging solder is driven by the increasing demand for miniaturized and efficient electronic devices, which require advanced packaging solutions. As technology continues to evolve, the need for innovative solder materials that can withstand various environmental conditions and provide robust performance is becoming more critical. This market is characterized by continuous research and development efforts to improve solder materials' properties, such as thermal conductivity, mechanical strength, and environmental compliance. Overall, the Global MEMS Packaging Solder Market is an essential component of the electronics industry, supporting the advancement of technology and the development of new applications.

Solder Wire, Solder Paste, Preformed Solder in the Global MEMS Packaging Solder Market:

Solder wire, solder paste, and preformed solder are three critical components in the Global MEMS Packaging Solder Market, each serving unique functions in the packaging process. Solder wire is a thin, flexible strand of solder material used primarily for manual soldering applications. It is often employed in situations where precision and control are required, such as in the repair or assembly of small electronic components. The wire is typically composed of a metal alloy, such as tin-lead or lead-free alternatives, designed to melt at specific temperatures to form strong, conductive joints. Solder paste, on the other hand, is a thick, viscous mixture of solder powder and flux, used predominantly in automated soldering processes like surface mount technology (SMT). The paste is applied to the circuit board using a stencil, and components are placed on top before the assembly is heated to reflow the solder, creating secure connections. This method is favored for its efficiency and ability to handle high-volume production. Preformed solder, also known as solder preforms, are precisely shaped pieces of solder material, available in various sizes and configurations to suit specific applications. These preforms are used in situations where uniformity and consistency are paramount, such as in the packaging of MEMS devices. They offer the advantage of precise control over the amount of solder used, reducing waste and ensuring reliable connections. Each of these solder forms plays a crucial role in the MEMS packaging process, providing the necessary electrical and mechanical connections that enable the functionality of these advanced devices. As the demand for smaller, more efficient electronic devices continues to grow, the development and refinement of solder materials and techniques remain a key focus within the industry. Manufacturers are continually exploring new alloys and formulations to enhance solder performance, addressing challenges such as thermal management, mechanical stress, and environmental impact. The choice of solder material and form depends on various factors, including the specific application, production volume, and desired performance characteristics. In the context of MEMS packaging, the ability to create reliable, high-quality connections is essential, as these devices often operate in demanding environments where failure is not an option. As a result, the Global MEMS Packaging Solder Market is characterized by ongoing innovation and adaptation, as companies strive to meet the evolving needs of the electronics industry.

Consumer Electronics, Automotive Electronics, Medical Industry, Others in the Global MEMS Packaging Solder Market:

The Global MEMS Packaging Solder Market finds extensive usage across various industries, including consumer electronics, automotive electronics, the medical industry, and others, each with unique requirements and challenges. In the consumer electronics sector, MEMS devices are integral to the functionality of smartphones, tablets, wearables, and other gadgets. These devices often require compact, lightweight packaging solutions that can withstand frequent handling and environmental exposure. Solder materials used in this sector must provide reliable electrical connections while maintaining the device's overall performance and durability. The automotive electronics industry also relies heavily on MEMS technology, with applications ranging from airbag sensors to advanced driver-assistance systems (ADAS). In this context, the packaging solder must endure harsh conditions, such as extreme temperatures and vibrations, ensuring the safety and reliability of the vehicle's electronic systems. The medical industry presents another critical application area for MEMS packaging solder, where devices like pacemakers, hearing aids, and diagnostic equipment demand high precision and reliability. Solder materials used in medical applications must comply with stringent regulatory standards, ensuring biocompatibility and long-term performance. Additionally, the solder must provide robust connections that can withstand sterilization processes and other environmental challenges. Beyond these primary industries, MEMS packaging solder is also utilized in various other applications, such as industrial automation, telecommunications, and aerospace. Each of these sectors presents unique demands, requiring tailored solder solutions that can meet specific performance criteria. For instance, in aerospace applications, solder materials must offer exceptional thermal and mechanical stability to function effectively in high-altitude and space environments. As technology continues to advance, the Global MEMS Packaging Solder Market is poised to play a crucial role in enabling the development of new applications and innovations across these diverse industries. The ongoing evolution of MEMS technology and the increasing demand for miniaturized, efficient electronic devices drive the need for advanced solder materials and packaging solutions. Manufacturers are continually exploring new alloys and formulations to enhance solder performance, addressing challenges such as thermal management, mechanical stress, and environmental impact. The ability to create reliable, high-quality connections is essential in the context of MEMS packaging, as these devices often operate in demanding environments where failure is not an option. As a result, the Global MEMS Packaging Solder Market is characterized by ongoing innovation and adaptation, as companies strive to meet the evolving needs of the electronics industry.

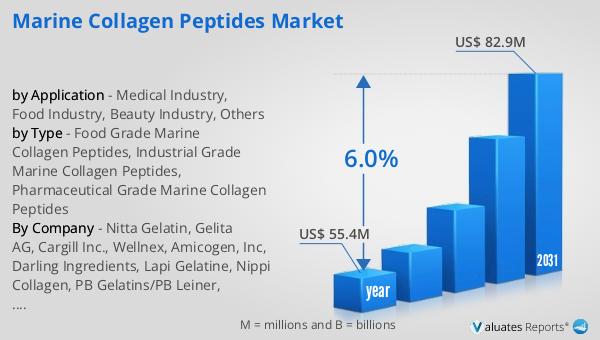

Global MEMS Packaging Solder Market Outlook:

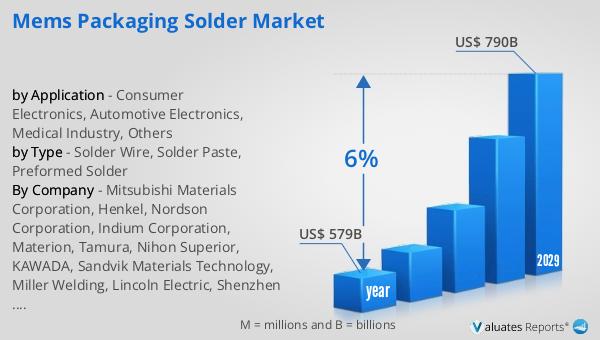

The global semiconductor market, valued at approximately $579 billion in 2022, is on a growth trajectory, with projections indicating it could reach around $790 billion by 2029. This growth is expected to occur at a compound annual growth rate (CAGR) of 6% over the forecast period. This upward trend reflects the increasing demand for semiconductors across various industries, driven by technological advancements and the proliferation of electronic devices. The semiconductor market is a critical component of the global economy, underpinning the development and functionality of a wide range of products, from consumer electronics to industrial machinery. As industries continue to innovate and integrate more sophisticated technologies, the demand for semiconductors is expected to rise, fueling market growth. The projected expansion of the semiconductor market underscores the importance of continued investment in research and development, as well as the need for robust supply chain management to meet the growing demand. This growth also highlights the significance of the Global MEMS Packaging Solder Market, as the packaging and interconnection of semiconductor devices are crucial to their performance and reliability. As the market evolves, companies within the semiconductor and MEMS packaging sectors must adapt to changing demands and technological advancements, ensuring they remain competitive and capable of meeting the needs of their customers. The anticipated growth of the semiconductor market presents both opportunities and challenges for industry players, emphasizing the need for strategic planning and innovation to capitalize on emerging trends and maintain a competitive edge.

| Report Metric | Details |

| Report Name | MEMS Packaging Solder Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2025 - 2029 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mitsubishi Materials Corporation, Henkel, Nordson Corporation, Indium Corporation, Materion, Tamura, Nihon Superior, KAWADA, Sandvik Materials Technology, Miller Welding, Lincoln Electric, Shenzhen Huamao Xiang Electronics, Shenzhen Fu Ying Da Industrial Technology, Morning Sun Technology, Kunpeng Precision Intelligent Technology, Guangzhou Xiangyi Electronic Technology, Guangzhou Pudi Lixin Technology, Suzhou Silicon Age Electronic Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |