What is Global Oral Rapid Prototyping Materials Market?

The Global Oral Rapid Prototyping Materials Market is an emerging sector that focuses on the development and utilization of materials specifically designed for rapid prototyping in the dental industry. This market is driven by the increasing demand for efficient and precise dental solutions, which are essential for creating accurate dental models, prosthetics, and other oral healthcare products. Rapid prototyping materials, such as metals and resins, are used to create detailed and functional prototypes quickly, allowing dental professionals to improve the design and functionality of dental products. The market is characterized by continuous advancements in material science and technology, which enhance the properties of these materials, making them more suitable for various dental applications. As the dental industry continues to evolve, the Global Oral Rapid Prototyping Materials Market is expected to grow, driven by the need for innovative solutions that improve patient outcomes and streamline dental procedures. This market plays a crucial role in the development of new dental technologies and products, contributing to the overall advancement of oral healthcare.

Metal, Resin in the Global Oral Rapid Prototyping Materials Market:

In the Global Oral Rapid Prototyping Materials Market, metals and resins are two primary categories of materials used for creating dental prototypes. Metals, such as titanium and cobalt-chromium alloys, are favored for their strength, durability, and biocompatibility. These materials are often used in the production of dental implants, crowns, and bridges, where structural integrity and longevity are paramount. Metal-based rapid prototyping allows for the creation of highly precise and customized dental components, which are essential for ensuring a perfect fit and optimal performance in the patient's mouth. The use of metal in rapid prototyping also facilitates the production of complex geometries that are difficult to achieve with traditional manufacturing methods. On the other hand, resin-based materials are popular for their versatility and ease of use. Resins, such as photopolymer resins, are used in stereolithography (SLA) and digital light processing (DLP) technologies to create detailed and accurate dental models. These materials are ideal for producing temporary crowns, bridges, and orthodontic appliances, as they can be easily shaped and modified to meet specific patient needs. Resin-based rapid prototyping is particularly advantageous in situations where quick turnaround times are required, as the materials cure rapidly and can be processed with minimal post-production work. Additionally, resins offer a wide range of aesthetic options, allowing dental professionals to match the color and translucency of natural teeth, which is crucial for achieving a natural-looking result. The choice between metal and resin materials in the Global Oral Rapid Prototyping Materials Market depends on the specific requirements of the dental application, including factors such as strength, aesthetics, and production speed. Both types of materials play a vital role in advancing dental technology and improving patient care by enabling the creation of high-quality, customized dental solutions. As the market continues to grow, ongoing research and development efforts are expected to further enhance the properties and capabilities of these materials, expanding their applications and driving innovation in the dental industry.

Hospital, Clinic in the Global Oral Rapid Prototyping Materials Market:

The usage of Global Oral Rapid Prototyping Materials Market in hospitals and clinics is transforming the way dental care is delivered, offering numerous benefits to both healthcare providers and patients. In hospitals, rapid prototyping materials are used to create precise dental models and prosthetics, which are essential for planning and executing complex dental procedures. These materials enable dental professionals to visualize and simulate the treatment process, ensuring that each step is carefully planned and executed with precision. This not only improves the accuracy of the procedure but also reduces the risk of complications, leading to better patient outcomes. In clinics, rapid prototyping materials are used to produce customized dental appliances, such as crowns, bridges, and dentures, which are tailored to the unique needs of each patient. The ability to create these appliances quickly and accurately allows dental professionals to provide timely and effective treatment, reducing the time patients spend in the dental chair and improving their overall experience. Additionally, the use of rapid prototyping materials in clinics enhances the quality of dental care by enabling the production of high-quality, durable, and aesthetically pleasing dental solutions. This is particularly important in cosmetic dentistry, where the appearance of the final product is a critical factor in patient satisfaction. The integration of rapid prototyping materials into hospital and clinic settings also streamlines the workflow, allowing dental professionals to focus on patient care rather than the technical aspects of production. This not only increases efficiency but also reduces costs, making dental care more accessible and affordable for patients. As the Global Oral Rapid Prototyping Materials Market continues to evolve, the adoption of these materials in hospitals and clinics is expected to increase, driving further advancements in dental technology and improving the quality of care provided to patients.

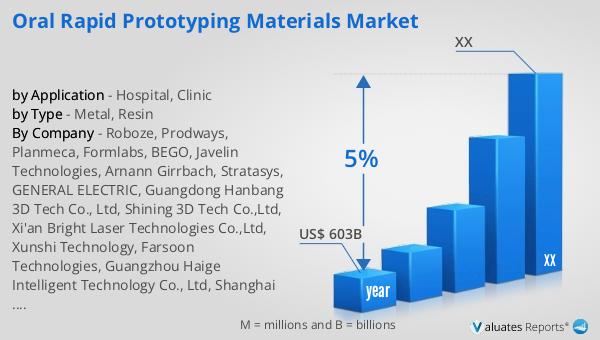

Global Oral Rapid Prototyping Materials Market Outlook:

Our research indicates that the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, an aging global population, and increasing demand for healthcare services. The expansion of the medical device market is expected to have a significant impact on the Global Oral Rapid Prototyping Materials Market, as dental professionals seek innovative solutions to meet the growing demand for high-quality dental care. The integration of rapid prototyping materials into dental practices is likely to become more prevalent as healthcare providers strive to improve patient outcomes and streamline their operations. This trend is expected to drive further research and development efforts in the field, leading to the creation of new and improved materials that enhance the capabilities of dental professionals. As the market continues to grow, the Global Oral Rapid Prototyping Materials Market is poised to play a crucial role in the advancement of dental technology and the delivery of superior oral healthcare.

| Report Metric | Details |

| Report Name | Oral Rapid Prototyping Materials Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Roboze, Prodways, Planmeca, Formlabs, BEGO, Javelin Technologies, Arnann Girrbach, Stratasys, GENERAL ELECTRIC, Guangdong Hanbang 3D Tech Co., Ltd, Shining 3D Tech Co.,Ltd, Xi'an Bright Laser Technologies Co.,Ltd, Xunshi Technology, Farsoon Technologies, Guangzhou Haige Intelligent Technology Co., Ltd, Shanghai Luen Thai Technology Co., Ltd, Suzhou Rhosai Intelligent Technology Co., Ltd, Qingfeng (Beijing) Technology Co., Ltd, Shanghai Puli Bioelectric Technology Co., Ltd, Nanjing Chenglian Laser Technology Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |