What is Global Nonwoven Fabrics for Liquid Filtration Market?

The Global Nonwoven Fabrics for Liquid Filtration Market is a specialized segment within the broader nonwoven fabrics industry. Nonwoven fabrics are materials made from fibers bonded together through chemical, mechanical, heat, or solvent treatment, rather than being woven or knitted. These fabrics are particularly useful in liquid filtration applications due to their unique properties, such as high permeability, durability, and the ability to trap fine particles. The market for nonwoven fabrics in liquid filtration is driven by the increasing demand for clean water, stringent environmental regulations, and the need for efficient filtration systems in various industries. These fabrics are used in a wide range of applications, including water and wastewater treatment, industrial processes, and the production of beverages and pharmaceuticals. The market is characterized by continuous innovation and the development of advanced materials that offer improved filtration efficiency and longer service life. As industries continue to prioritize sustainability and operational efficiency, the demand for nonwoven fabrics for liquid filtration is expected to grow steadily.

PET, PP, Others in the Global Nonwoven Fabrics for Liquid Filtration Market:

Polyethylene terephthalate (PET) and polypropylene (PP) are two of the most commonly used materials in the Global Nonwoven Fabrics for Liquid Filtration Market. PET is a type of polyester that is known for its strength, durability, and resistance to chemicals and moisture. These properties make PET nonwoven fabrics ideal for use in harsh environments where they are exposed to various chemicals and high temperatures. PET fabrics are often used in applications such as water filtration, where they help to remove contaminants and improve water quality. On the other hand, polypropylene (PP) is a thermoplastic polymer that is lightweight, resistant to chemicals, and has excellent mechanical properties. PP nonwoven fabrics are widely used in liquid filtration due to their high filtration efficiency, low cost, and ease of processing. They are commonly used in applications such as oil and gas filtration, where they help to remove impurities and ensure the purity of the final product. In addition to PET and PP, other materials such as nylon, cellulose, and glass fibers are also used in the production of nonwoven fabrics for liquid filtration. Each of these materials offers unique properties that make them suitable for specific applications. For example, nylon nonwoven fabrics are known for their high tensile strength and resistance to abrasion, making them ideal for use in industrial filtration processes. Cellulose nonwoven fabrics, on the other hand, are biodegradable and environmentally friendly, making them a popular choice for applications where sustainability is a priority. Glass fiber nonwoven fabrics are known for their high temperature resistance and are often used in applications where extreme heat is a concern. The choice of material for nonwoven fabrics in liquid filtration depends on various factors, including the specific requirements of the application, the type of contaminants to be removed, and the operating conditions. Manufacturers in the Global Nonwoven Fabrics for Liquid Filtration Market continue to innovate and develop new materials that offer improved performance and meet the evolving needs of different industries.

Automotive, Food and Beverage, Healthcare, Hydrocarbon Processing, Oil & Gas, Others in the Global Nonwoven Fabrics for Liquid Filtration Market:

The Global Nonwoven Fabrics for Liquid Filtration Market finds extensive usage across various industries, including automotive, food and beverage, healthcare, hydrocarbon processing, and oil and gas. In the automotive industry, nonwoven fabrics are used in filtration systems to ensure the purity of fluids such as engine oil, fuel, and coolant. These fabrics help to remove contaminants and improve the performance and longevity of automotive components. In the food and beverage industry, nonwoven fabrics are used in the filtration of liquids such as water, juice, and beer. They help to remove impurities and ensure the safety and quality of the final product. In the healthcare industry, nonwoven fabrics are used in the filtration of liquids such as blood, plasma, and intravenous fluids. They help to remove contaminants and ensure the safety and efficacy of medical treatments. In the hydrocarbon processing industry, nonwoven fabrics are used in the filtration of liquids such as crude oil, natural gas, and petrochemicals. They help to remove impurities and improve the efficiency of refining processes. In the oil and gas industry, nonwoven fabrics are used in the filtration of drilling fluids, produced water, and other liquids. They help to remove contaminants and ensure the purity of the final product. In addition to these industries, nonwoven fabrics for liquid filtration are also used in other applications such as water and wastewater treatment, industrial processes, and the production of beverages and pharmaceuticals. The versatility and effectiveness of nonwoven fabrics make them an essential component in various filtration systems, helping to improve the quality and safety of liquids across different industries.

Global Nonwoven Fabrics for Liquid Filtration Market Outlook:

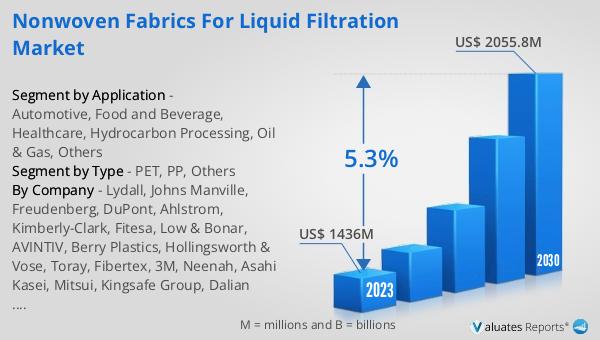

The global market for Nonwoven Fabrics for Liquid Filtration was valued at approximately US$ 1436 million in 2023. Projections indicate that this market is expected to grow significantly, reaching an estimated value of US$ 2055.8 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. The increasing demand for efficient filtration systems across various industries, coupled with stringent environmental regulations and the need for clean water, are key factors driving this market growth. As industries continue to prioritize sustainability and operational efficiency, the demand for advanced nonwoven fabrics for liquid filtration is expected to rise. This market outlook highlights the potential for significant growth and innovation in the Global Nonwoven Fabrics for Liquid Filtration Market over the coming years.

| Report Metric | Details |

| Report Name | Nonwoven Fabrics for Liquid Filtration Market |

| Accounted market size in 2023 | US$ 1436 million |

| Forecasted market size in 2030 | US$ 2055.8 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lydall, Johns Manville, Freudenberg, DuPont, Ahlstrom, Kimberly-Clark, Fitesa, Low & Bonar, AVINTIV, Berry Plastics, Hollingsworth & Vose, Toray, Fibertex, 3M, Neenah, Asahi Kasei, Mitsui, Kingsafe Group, Dalian Ruiguang Group, Beautiful Nonwoven, Zisun Technology, Xinlong Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |