What is Global Benzoates Plasticizers Market?

The Global Benzoates Plasticizers Market refers to the worldwide industry involved in the production, distribution, and application of benzoate-based plasticizers. Plasticizers are additives that increase the plasticity or fluidity of materials, particularly polymers. Benzoates plasticizers are derived from benzoic acid and are used to enhance the flexibility, durability, and workability of various plastic products. These plasticizers are particularly valued for their low volatility, high efficiency, and environmental friendliness compared to traditional phthalate plasticizers. The market encompasses a wide range of applications, including flooring and wall coverings, films and sheets, wires and cables, coated fabrics, consumer goods, medicinal products, food packaging, toys, and other miscellaneous uses. The demand for benzoates plasticizers is driven by the growing need for flexible and durable plastic products in various industries, coupled with increasing regulatory pressures to replace phthalates with safer alternatives. The market is characterized by a diverse range of manufacturers, suppliers, and end-users, all contributing to the dynamic and evolving landscape of the global benzoates plasticizers industry.

PVC, PE, PET, Others in the Global Benzoates Plasticizers Market:

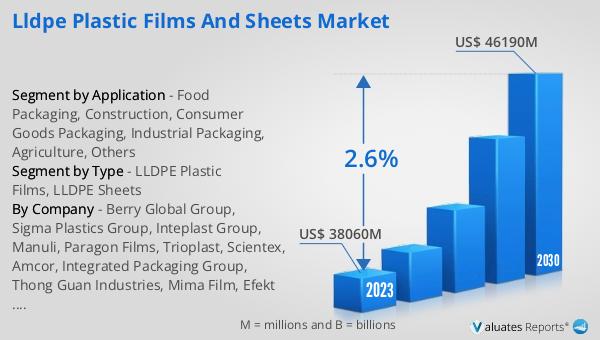

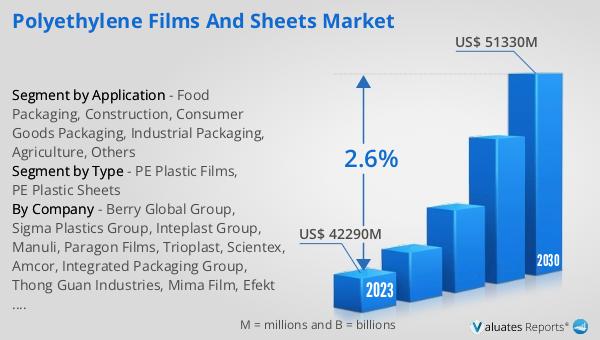

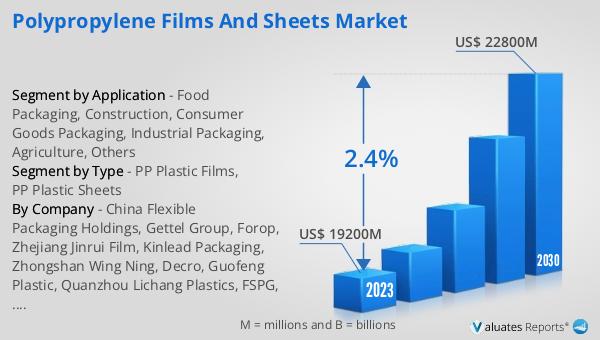

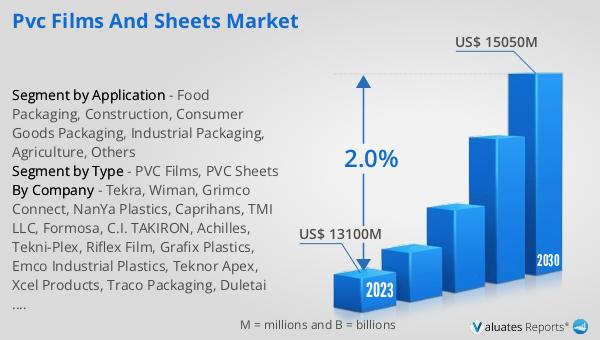

Polyvinyl Chloride (PVC), Polyethylene (PE), Polyethylene Terephthalate (PET), and other polymers are significant segments within the Global Benzoates Plasticizers Market. PVC is one of the most widely used plastics globally, known for its versatility and cost-effectiveness. It is commonly used in construction materials, pipes, medical devices, and packaging. Benzoates plasticizers are added to PVC to enhance its flexibility and durability, making it suitable for a wide range of applications. Polyethylene (PE) is another major polymer that benefits from the addition of benzoates plasticizers. PE is used in various forms, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE), and is found in products such as plastic bags, bottles, and containers. The plasticizers improve the material's flexibility and processability, making it easier to manufacture and use in different applications. Polyethylene Terephthalate (PET) is a type of polyester commonly used in the production of plastic bottles, food containers, and synthetic fibers. The addition of benzoates plasticizers to PET enhances its mechanical properties, making it more suitable for packaging and textile applications. Other polymers that benefit from benzoates plasticizers include polypropylene (PP), polystyrene (PS), and various elastomers. These materials are used in a wide range of products, from automotive parts to consumer electronics, and the plasticizers help improve their performance and longevity. The use of benzoates plasticizers in these polymers is driven by the need for safer, more efficient, and environmentally friendly alternatives to traditional plasticizers. As regulatory pressures increase and consumer awareness grows, the demand for benzoates plasticizers in these polymer segments is expected to continue to rise, driving innovation and growth in the market.

Flooring & Wall Coverings, Film & Sheet, Wire & Cable, Coated Fabric, Consumer Goods, Medicinal, Food, Toys, Others in the Global Benzoates Plasticizers Market:

The Global Benzoates Plasticizers Market finds extensive usage in various applications, including flooring and wall coverings, films and sheets, wires and cables, coated fabrics, consumer goods, medicinal products, food packaging, toys, and other miscellaneous uses. In flooring and wall coverings, benzoates plasticizers are used to enhance the flexibility and durability of vinyl flooring, making it more resistant to wear and tear. This makes it an ideal choice for both residential and commercial spaces. In the film and sheet industry, benzoates plasticizers are added to improve the flexibility and processability of plastic films, which are used in packaging, agriculture, and construction. The enhanced properties of these films make them more durable and easier to handle. In the wire and cable industry, benzoates plasticizers are used to improve the flexibility and insulation properties of PVC cables, making them more resistant to heat and mechanical stress. This is crucial for ensuring the safety and longevity of electrical installations. Coated fabrics, which are used in products such as upholstery, tarpaulins, and protective clothing, also benefit from the addition of benzoates plasticizers. These plasticizers enhance the flexibility and durability of the coated fabrics, making them more resistant to environmental factors such as UV radiation and moisture. In the consumer goods sector, benzoates plasticizers are used in a wide range of products, from toys to household items, to improve their flexibility and durability. This is particularly important for products that are subject to frequent handling and use. In the medicinal field, benzoates plasticizers are used in the production of medical devices and packaging materials, where their low toxicity and high efficiency are crucial. In the food packaging industry, benzoates plasticizers are used to improve the flexibility and durability of plastic packaging materials, ensuring the safety and integrity of food products. In the toy industry, benzoates plasticizers are used to enhance the flexibility and safety of plastic toys, making them more durable and less likely to break. Other miscellaneous uses of benzoates plasticizers include applications in automotive parts, consumer electronics, and various industrial products. The versatility and efficiency of benzoates plasticizers make them a valuable additive in a wide range of applications, driving their demand in the global market.

Global Benzoates Plasticizers Market Outlook:

The global Benzoates Plasticizers market was valued at US$ 825 million in 2023 and is anticipated to reach US$ 997.4 million by 2030, witnessing a CAGR of 2.6% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for safer and more efficient plasticizers across various industries. The market's expansion is driven by the need for flexible and durable plastic products, coupled with regulatory pressures to replace traditional phthalate plasticizers with safer alternatives. The diverse range of applications, from flooring and wall coverings to medical devices and food packaging, highlights the versatility and importance of benzoates plasticizers in the global market. As industries continue to seek environmentally friendly and high-performance plasticizers, the demand for benzoates plasticizers is expected to grow, driving innovation and development in the market. The market's growth trajectory underscores the critical role of benzoates plasticizers in enhancing the properties and performance of various plastic products, making them an essential component in the modern manufacturing landscape.

| Report Metric | Details |

| Report Name | Benzoates Plasticizers Market |

| Accounted market size in 2023 | US$ 825 million |

| Forecasted market size in 2030 | US$ 997.4 million |

| CAGR | 2.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | UPC Group, Bluesail, Exxonmobil, Henan Qing'an Chemical Hi-Tech, Nan Ya Plastics, Aekyung Petrochemical, Evonik, Hongxin Chemical, Anqing Sheng Feng Chemical, Basf, Eastman |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |