What is Global Hydrocarbon Based Cleaner Market?

The Global Hydrocarbon Based Cleaner Market refers to the worldwide industry focused on the production and distribution of cleaning agents that utilize hydrocarbons as their primary active ingredients. Hydrocarbon-based cleaners are widely used due to their effectiveness in dissolving oils, greases, and other organic substances. These cleaners are essential in various industries, including automotive, manufacturing, and maintenance, where they help in maintaining machinery, equipment, and surfaces. The market encompasses a range of products, from solvents and degreasers to specialized cleaning solutions tailored for specific applications. The demand for hydrocarbon-based cleaners is driven by their efficiency, cost-effectiveness, and versatility, making them a preferred choice for industrial and commercial cleaning needs. As industries continue to grow and the need for effective cleaning solutions increases, the Global Hydrocarbon Based Cleaner Market is expected to expand, offering new opportunities for innovation and development in cleaning technologies.

Normal Hydrocarbon, Isohydrocarbon, Naphthenic, Others in the Global Hydrocarbon Based Cleaner Market:

Normal hydrocarbons, isohydrocarbons, naphthenic hydrocarbons, and other types of hydrocarbons play distinct roles in the Global Hydrocarbon Based Cleaner Market. Normal hydrocarbons, also known as alkanes, are straight-chain molecules that are highly effective in dissolving oils and greases. They are commonly used in general-purpose cleaning applications due to their strong solvency power and relatively low toxicity. Isohydrocarbons, on the other hand, are branched-chain molecules that offer a balance between solvency and evaporation rate. This makes them suitable for applications where quick drying is essential, such as in electronics cleaning or precision parts cleaning. Naphthenic hydrocarbons, which are cyclic in structure, provide excellent solvency for heavy-duty cleaning tasks. They are often used in industrial settings where robust cleaning power is required to remove stubborn contaminants. Other hydrocarbons, including aromatic hydrocarbons, offer unique properties that make them suitable for specialized cleaning applications. Aromatic hydrocarbons, for example, have high solvency power and are used in formulations where strong cleaning action is needed. Each type of hydrocarbon brings its own set of advantages and limitations, allowing manufacturers to tailor their cleaning solutions to meet specific industry requirements. The diversity of hydrocarbons available in the market ensures that there is a suitable cleaner for virtually any cleaning challenge, from light-duty maintenance to heavy industrial cleaning. This versatility is a key factor driving the growth and innovation within the Global Hydrocarbon Based Cleaner Market.

Metal Processing, Food and Beverage, Building Service, Engineering Machinery, Vehicle Cleaning, Others in the Global Hydrocarbon Based Cleaner Market:

The usage of hydrocarbon-based cleaners spans across various industries, each with its unique requirements and challenges. In metal processing, these cleaners are essential for removing oils, greases, and other contaminants from metal surfaces before further processing or assembly. They ensure that metal parts are clean and free from residues that could affect the quality of welding, painting, or coating processes. In the food and beverage industry, hydrocarbon-based cleaners are used to maintain hygiene and cleanliness in processing equipment and facilities. They help in removing organic residues and ensuring that surfaces are free from contaminants that could compromise food safety. Building services also rely on these cleaners for maintaining cleanliness in commercial and residential buildings. They are used for cleaning floors, walls, and other surfaces, providing an effective solution for removing dirt, grime, and stains. In the field of engineering machinery, hydrocarbon-based cleaners play a crucial role in maintaining the performance and longevity of equipment. They are used to clean engines, gears, and other mechanical parts, ensuring that they operate smoothly and efficiently. Vehicle cleaning is another significant application area, where these cleaners are used to remove dirt, grease, and road grime from vehicles, both inside and out. They help in maintaining the appearance and functionality of vehicles, from cars and trucks to heavy-duty machinery. Other industries, such as aerospace, electronics, and healthcare, also benefit from the use of hydrocarbon-based cleaners. These cleaners provide a reliable and effective solution for maintaining cleanliness and hygiene in various settings, contributing to the overall efficiency and safety of operations.

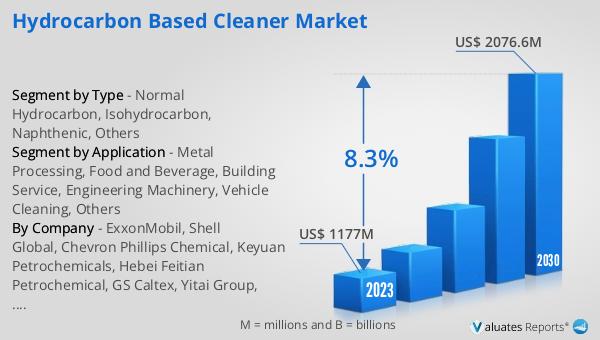

Global Hydrocarbon Based Cleaner Market Outlook:

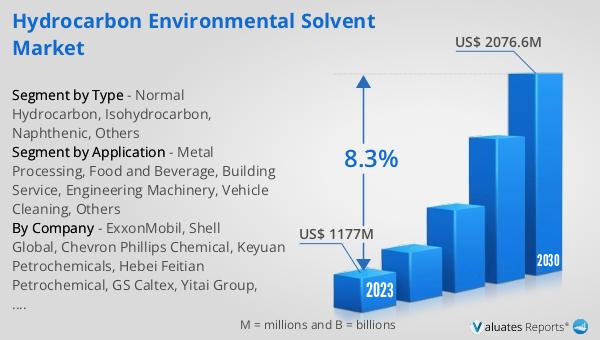

The global Hydrocarbon Based Cleaner market was valued at US$ 1177 million in 2023 and is anticipated to reach US$ 2076.6 million by 2030, witnessing a CAGR of 8.3% during the forecast period 2024-2030. This significant growth reflects the increasing demand for effective and versatile cleaning solutions across various industries. As businesses continue to prioritize cleanliness and maintenance, the need for hydrocarbon-based cleaners is expected to rise. These cleaners offer a cost-effective and efficient solution for removing oils, greases, and other contaminants, making them a preferred choice for industrial and commercial applications. The projected growth of the market indicates a positive outlook for the industry, with opportunities for innovation and development in cleaning technologies. Companies operating in this market are likely to invest in research and development to create more advanced and environmentally friendly cleaning solutions. The expanding market also suggests a growing awareness of the importance of cleanliness and hygiene in various sectors, from manufacturing and automotive to food and beverage and healthcare. As the market continues to evolve, it will be essential for companies to stay ahead of trends and meet the changing needs of their customers.

| Report Metric | Details |

| Report Name | Hydrocarbon Based Cleaner Market |

| Accounted market size in 2023 | US$ 1177 million |

| Forecasted market size in 2030 | US$ 2076.6 million |

| CAGR | 8.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ExxonMobil, Shell Global, Chevron Phillips Chemical, Keyuan Petrochemicals, Hebei Feitian Petrochemical, GS Caltex, Yitai Group, TotalEnergies, INEOS, Idemitsu Kosan, DowPol |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |