What is Global Automotive Seat Pressure Control System Market?

The Global Automotive Seat Pressure Control System Market is a specialized segment within the broader automotive industry, focusing on enhancing the comfort and ergonomics of vehicle seats. These systems are designed to adjust the pressure distribution across the seat to provide optimal support and comfort for the occupant. This is particularly important for long-distance driving, where improper seat pressure can lead to discomfort and even health issues like back pain. The market encompasses various technologies and components, including sensors, actuators, and control units, which work together to monitor and adjust seat pressure in real-time. These systems are increasingly being integrated into both passenger and commercial vehicles, driven by consumer demand for enhanced comfort and the automotive industry's focus on advanced driver assistance systems (ADAS) and overall vehicle ergonomics. The market is also influenced by regulatory standards related to vehicle safety and ergonomics, which mandate certain levels of comfort and support in automotive seating. As a result, the Global Automotive Seat Pressure Control System Market is poised for significant growth, driven by technological advancements and increasing consumer awareness about the benefits of ergonomic seating solutions.

Pneumatic Support System, Pneumatic Massage System in the Global Automotive Seat Pressure Control System Market:

The Pneumatic Support System and Pneumatic Massage System are two key components within the Global Automotive Seat Pressure Control System Market. The Pneumatic Support System primarily focuses on providing adjustable lumbar and lateral support to the vehicle occupant. This system uses air bladders that can be inflated or deflated to adjust the firmness and contour of the seat, thereby offering personalized support based on the occupant's body shape and seating preferences. The system is controlled via a set of sensors and actuators that continuously monitor the pressure distribution and make real-time adjustments to ensure optimal comfort. On the other hand, the Pneumatic Massage System aims to enhance the overall seating experience by incorporating massage functionalities into the seat. This system uses a series of air bladders and valves to create a massaging effect, which can help reduce fatigue and improve blood circulation during long drives. The massage patterns and intensity can be customized through a user interface, allowing occupants to choose from various massage modes such as rolling, kneading, and tapping. Both systems are integrated into the vehicle's central control unit, enabling seamless operation and synchronization with other in-car systems. The integration of these pneumatic systems not only enhances comfort but also contributes to the overall safety and well-being of the occupants by reducing the risk of musculoskeletal issues. As consumer demand for luxury and comfort features in vehicles continues to rise, the adoption of Pneumatic Support and Massage Systems is expected to grow, making them essential components in modern automotive seat pressure control solutions.

Passenger Vehicle, Commercial Vehicle in the Global Automotive Seat Pressure Control System Market:

The usage of Global Automotive Seat Pressure Control Systems in passenger vehicles and commercial vehicles varies based on the specific needs and requirements of the occupants. In passenger vehicles, these systems are primarily focused on enhancing comfort and luxury. Modern passenger vehicles, especially in the premium and luxury segments, are increasingly equipped with advanced seat pressure control systems that offer personalized seating adjustments. These systems use a combination of sensors, actuators, and control units to monitor and adjust the seat pressure in real-time, ensuring optimal comfort for the driver and passengers. Features such as adjustable lumbar support, lateral support, and massage functionalities are commonly integrated into these systems, providing a high level of customization and comfort. The primary goal is to enhance the overall driving experience by reducing fatigue and discomfort, especially during long journeys. In commercial vehicles, the focus shifts towards improving ergonomics and reducing the risk of musculoskeletal issues for drivers who spend long hours on the road. Commercial vehicles, such as trucks and buses, are increasingly being equipped with seat pressure control systems that offer adjustable support and pressure distribution. These systems help in reducing the physical strain on drivers, thereby improving their overall health and well-being. Additionally, by enhancing driver comfort, these systems can also contribute to improved driver performance and safety. The integration of seat pressure control systems in commercial vehicles is driven by the need to comply with regulatory standards related to driver ergonomics and safety. Overall, the adoption of Global Automotive Seat Pressure Control Systems in both passenger and commercial vehicles is driven by the growing awareness of the importance of ergonomic seating solutions and the increasing demand for comfort and safety features in modern vehicles.

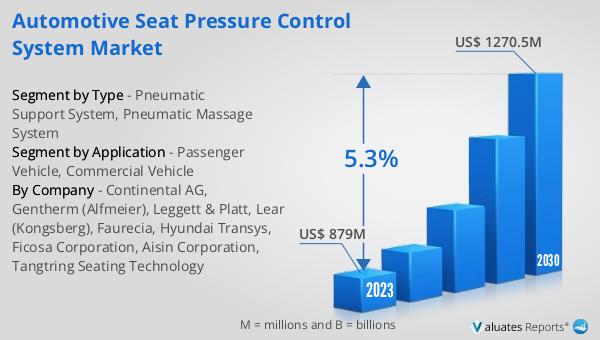

Global Automotive Seat Pressure Control System Market Outlook:

The global Automotive Seat Pressure Control System market was valued at US$ 879 million in 2023 and is anticipated to reach US$ 1270.5 million by 2030, witnessing a CAGR of 5.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for advanced seating solutions that enhance comfort and ergonomics in vehicles. As consumers become more aware of the benefits of ergonomic seating, the demand for seat pressure control systems is expected to rise. Additionally, the automotive industry's focus on advanced driver assistance systems (ADAS) and overall vehicle ergonomics is further propelling the market growth. The integration of technologies such as sensors, actuators, and control units into seat pressure control systems is enabling real-time monitoring and adjustment of seat pressure, providing personalized comfort and support to occupants. The market is also influenced by regulatory standards related to vehicle safety and ergonomics, which mandate certain levels of comfort and support in automotive seating. As a result, the Global Automotive Seat Pressure Control System Market is poised for significant growth, driven by technological advancements and increasing consumer awareness about the benefits of ergonomic seating solutions.

| Report Metric | Details |

| Report Name | Automotive Seat Pressure Control System Market |

| Accounted market size in 2023 | US$ 879 million |

| Forecasted market size in 2030 | US$ 1270.5 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Continental AG, Gentherm (Alfmeier), Leggett & Platt, Lear (Kongsberg), Faurecia, Hyundai Transys, Ficosa Corporation, Aisin Corporation, Tangtring Seating Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |