What is Global Digital Salinity Meters Market?

The Global Digital Salinity Meters Market is a specialized segment within the broader instrumentation and measurement industry. Digital salinity meters are devices used to measure the salt concentration in various solutions, which is crucial for numerous applications across different industries. These meters provide accurate and reliable readings, making them indispensable tools for quality control, research, and environmental monitoring. The market for digital salinity meters has been growing steadily due to increasing demand from sectors such as agriculture, food and beverage, pharmaceuticals, and environmental science. The rise in global awareness about water quality and the need for precise salinity measurements in various industrial processes have further fueled the market's expansion. Technological advancements have also played a significant role in enhancing the functionality and user-friendliness of these meters, making them more accessible to a broader range of users. As industries continue to prioritize quality and efficiency, the demand for digital salinity meters is expected to remain robust.

Pen-Style Meters, Pocket Meters, Others in the Global Digital Salinity Meters Market:

Pen-style meters, pocket meters, and other types of digital salinity meters each serve unique purposes and cater to different user needs within the Global Digital Salinity Meters Market. Pen-style meters are compact, portable devices that resemble a pen, making them highly convenient for on-the-go measurements. These meters are particularly popular in fieldwork and laboratory settings where quick and easy salinity checks are required. They are user-friendly, often featuring a simple interface and digital display, which allows for immediate reading of results. Pen-style meters are typically used in applications where space is limited, and portability is a priority, such as in agriculture for soil salinity testing or in aquaculture for monitoring water quality. Pocket meters, on the other hand, are slightly larger than pen-style meters but still maintain a high degree of portability. They often come with more advanced features, such as data logging, temperature compensation, and higher accuracy levels. Pocket meters are ideal for professionals who need a reliable and precise tool for regular use. These meters are commonly used in the food and beverage industry to ensure the quality and consistency of products, as well as in the pharmaceutical industry for precise measurements in various formulations. The robust design of pocket meters makes them suitable for harsh environments, such as in the oil and gas industry, where they can be used to monitor the salinity of drilling fluids and other solutions. Other types of digital salinity meters include benchtop meters and industrial-grade meters. Benchtop meters are designed for laboratory use and offer the highest level of accuracy and functionality. They are equipped with advanced features such as multi-parameter testing, large digital displays, and connectivity options for data transfer and analysis. These meters are essential in research and development settings where precise and comprehensive salinity measurements are required. Industrial-grade meters are built to withstand extreme conditions and are used in large-scale industrial applications. They are often integrated into automated systems for continuous monitoring and control of salinity levels in processes such as water treatment, chemical manufacturing, and environmental monitoring. Each type of digital salinity meter has its own set of advantages and is chosen based on the specific requirements of the application. The versatility and range of options available in the Global Digital Salinity Meters Market ensure that there is a suitable solution for every need, from simple field measurements to complex industrial processes. As technology continues to advance, these meters are becoming more sophisticated, offering greater accuracy, ease of use, and integration capabilities, further driving their adoption across various industries.

Chemical Industry, Oil and Gas Industry, Pharmaceutical Industry, Food and Beverage Industry, Agriculture, Others in the Global Digital Salinity Meters Market:

The usage of digital salinity meters spans across multiple industries, each with its unique requirements and applications. In the chemical industry, digital salinity meters are crucial for maintaining the quality and consistency of chemical products. Accurate salinity measurements are essential for various chemical processes, including the production of solvents, acids, and other chemical compounds. These meters help ensure that the chemical reactions occur under optimal conditions, thereby improving product quality and reducing waste. In the oil and gas industry, digital salinity meters play a vital role in monitoring the salinity of drilling fluids and other solutions used in exploration and production activities. High salinity levels can affect the efficiency of drilling operations and the integrity of equipment. By providing accurate salinity measurements, these meters help in optimizing the formulation of drilling fluids, enhancing the efficiency of drilling operations, and preventing equipment corrosion. The pharmaceutical industry relies on digital salinity meters for precise measurements in the formulation of various drugs and medical solutions. Accurate salinity levels are critical for ensuring the efficacy and safety of pharmaceutical products. These meters are used in quality control processes to verify that the salinity levels of raw materials and finished products meet the required standards. This helps in maintaining the consistency and quality of pharmaceutical products, thereby ensuring patient safety. In the food and beverage industry, digital salinity meters are used to monitor the salt content in various food products and beverages. Accurate salinity measurements are essential for maintaining the taste, quality, and safety of food products. These meters are used in the production of processed foods, dairy products, beverages, and other food items to ensure that the salt content is within the desired range. This helps in maintaining product consistency and meeting regulatory standards. Agriculture is another sector where digital salinity meters find extensive use. Soil salinity is a critical factor that affects crop growth and yield. High salinity levels can lead to poor crop performance and reduced agricultural productivity. Digital salinity meters are used by farmers and agricultural researchers to monitor soil salinity levels and make informed decisions about irrigation and soil management practices. This helps in optimizing crop growth and improving agricultural productivity. Other industries that use digital salinity meters include environmental monitoring, aquaculture, and water treatment. In environmental monitoring, these meters are used to assess the salinity levels of water bodies, which is essential for maintaining the health of aquatic ecosystems. In aquaculture, digital salinity meters are used to monitor the salinity levels of water in fish farms, ensuring optimal conditions for fish growth and health. In water treatment, these meters are used to monitor the salinity levels of water being treated, ensuring that the treated water meets the required quality standards. Overall, the versatility and accuracy of digital salinity meters make them indispensable tools across various industries. Their ability to provide precise and reliable salinity measurements helps in maintaining product quality, optimizing processes, and ensuring regulatory compliance. As industries continue to prioritize quality and efficiency, the demand for digital salinity meters is expected to remain strong.

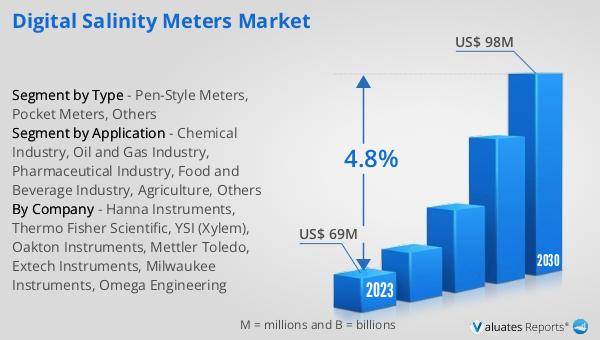

Global Digital Salinity Meters Market Outlook:

The global Digital Salinity Meters market, valued at US$ 69 million in 2023, is projected to grow significantly, reaching an estimated value of US$ 98 million by 2030. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.8% during the forecast period from 2024 to 2030. The increasing demand for accurate and reliable salinity measurements across various industries is a key driver of this market expansion. Industries such as agriculture, pharmaceuticals, food and beverage, and environmental monitoring are increasingly adopting digital salinity meters to ensure quality control, optimize processes, and comply with regulatory standards. Technological advancements in digital salinity meters, such as enhanced accuracy, user-friendly interfaces, and advanced data logging capabilities, are also contributing to the market's growth. These advancements make the meters more accessible and efficient for a broader range of applications, further driving their adoption. As industries continue to prioritize quality and efficiency, the demand for digital salinity meters is expected to remain robust, supporting the market's steady growth.

| Report Metric | Details |

| Report Name | Digital Salinity Meters Market |

| Accounted market size in 2023 | US$ 69 million |

| Forecasted market size in 2030 | US$ 98 million |

| CAGR | 4.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hanna Instruments, Thermo Fisher Scientific, YSI (Xylem), Oakton Instruments, Mettler Toledo, Extech Instruments, Milwaukee Instruments, Omega Engineering |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |