What is Global Compostable Cellophane Film Market?

The Global Compostable Cellophane Film Market is a rapidly growing sector focused on providing sustainable and eco-friendly alternatives to traditional plastic films. Compostable cellophane film is made from natural cellulose derived from wood, cotton, or other plant sources. Unlike conventional plastic films, which can take hundreds of years to decompose, compostable cellophane breaks down into non-toxic components within a few months under composting conditions. This makes it an attractive option for businesses and consumers looking to reduce their environmental footprint. The market for compostable cellophane film is driven by increasing awareness about environmental issues, stringent government regulations on plastic use, and a growing preference for sustainable packaging solutions. Companies in this market are continuously innovating to improve the performance and cost-effectiveness of compostable cellophane films, making them more competitive with traditional plastic films. As a result, the global compostable cellophane film market is expected to see significant growth in the coming years, driven by both consumer demand and regulatory pressures.

Sugarcane Starch Plastic Bag, Potato Starch Plastic Bag, Corn Starch Plastic Bag, Others in the Global Compostable Cellophane Film Market:

Sugarcane starch plastic bags are a popular alternative in the global compostable cellophane film market. These bags are made from the by-products of sugarcane processing, specifically the fibrous residue left after extracting the juice. This residue is converted into a biodegradable plastic that can be used to make bags. Sugarcane starch plastic bags are not only compostable but also have a lower carbon footprint compared to traditional plastic bags. They are strong, durable, and can be used for a variety of applications, including grocery bags, trash bags, and packaging materials. Potato starch plastic bags are another eco-friendly option in the compostable cellophane film market. These bags are made from the starch extracted from potatoes, which is then processed into a biodegradable plastic. Potato starch plastic bags are known for their strength and flexibility, making them suitable for a wide range of uses. They are also compostable and break down into non-toxic components, making them an environmentally friendly choice. Corn starch plastic bags are made from the starch derived from corn. These bags are biodegradable and compostable, breaking down into natural components that do not harm the environment. Corn starch plastic bags are used in various applications, including food packaging, shopping bags, and agricultural films. They are known for their durability and versatility, making them a popular choice in the compostable cellophane film market. Other types of compostable plastic bags include those made from materials like cassava starch, wheat starch, and other plant-based sources. These bags offer similar benefits to sugarcane, potato, and corn starch plastic bags, including biodegradability and compostability. They are used in a variety of applications, from food packaging to agricultural films, and are an important part of the global compostable cellophane film market. As the demand for sustainable packaging solutions continues to grow, the market for compostable plastic bags made from various plant-based sources is expected to expand, offering consumers and businesses more eco-friendly options.

Food and Beverages, Industrial, Others in the Global Compostable Cellophane Film Market:

The global compostable cellophane film market finds extensive usage in various sectors, including food and beverages, industrial applications, and other areas. In the food and beverages sector, compostable cellophane film is used for packaging a wide range of products, including fresh produce, baked goods, snacks, and ready-to-eat meals. The film provides an effective barrier against moisture and oxygen, helping to preserve the freshness and quality of the food. Additionally, compostable cellophane film is transparent, allowing consumers to see the product inside, which can enhance the appeal of the packaging. The use of compostable cellophane film in food packaging also aligns with the growing consumer demand for sustainable and eco-friendly products. In industrial applications, compostable cellophane film is used for packaging various products, including electronics, textiles, and automotive parts. The film provides protection against dust, moisture, and other environmental factors, helping to ensure the integrity and quality of the packaged products. Additionally, the use of compostable cellophane film in industrial packaging can help companies reduce their environmental footprint and comply with regulations on plastic use. Other areas where compostable cellophane film is used include personal care products, pharmaceuticals, and agricultural films. In the personal care sector, compostable cellophane film is used for packaging items like soaps, shampoos, and lotions. The film provides an effective barrier against moisture and contaminants, helping to preserve the quality of the products. In the pharmaceutical sector, compostable cellophane film is used for packaging medications and medical devices, providing protection against moisture and other environmental factors. In agriculture, compostable cellophane film is used for mulching and other applications, helping to improve crop yields and reduce the environmental impact of farming. Overall, the global compostable cellophane film market is driven by the growing demand for sustainable packaging solutions across various sectors.

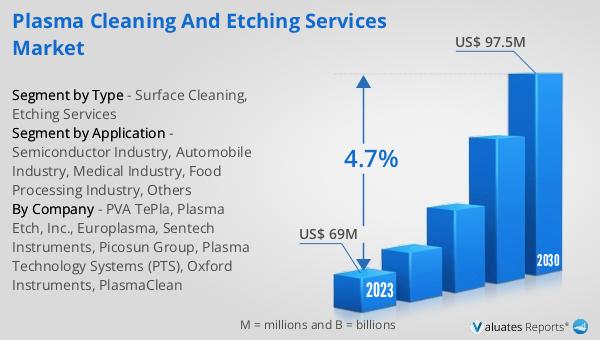

Global Compostable Cellophane Film Market Outlook:

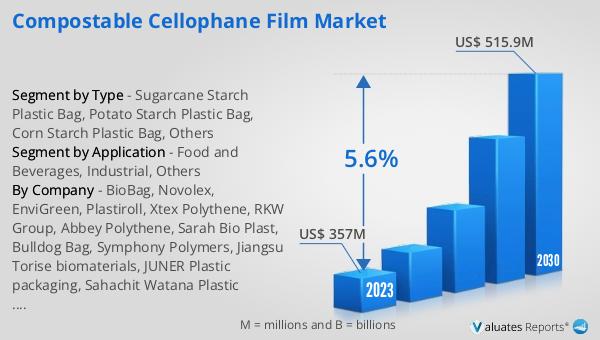

The global compostable cellophane film market was valued at $357 million in 2023 and is projected to reach $515.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2024 to 2030. This growth is driven by increasing consumer awareness about environmental issues, stringent government regulations on plastic use, and a growing preference for sustainable packaging solutions. Companies in the market are continuously innovating to improve the performance and cost-effectiveness of compostable cellophane films, making them more competitive with traditional plastic films. As a result, the global compostable cellophane film market is expected to see significant growth in the coming years, driven by both consumer demand and regulatory pressures.

| Report Metric | Details |

| Report Name | Compostable Cellophane Film Market |

| Accounted market size in 2023 | US$ 357 million |

| Forecasted market size in 2030 | US$ 515.9 million |

| CAGR | 5.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BioBag, Novolex, EnviGreen, Plastiroll, Xtex Polythene, RKW Group, Abbey Polythene, Sarah Bio Plast, Bulldog Bag, Symphony Polymers, Jiangsu Torise biomaterials, JUNER Plastic packaging, Sahachit Watana Plastic Industry, Walki Plastiroll Oy, Chnpack, XCBIO, Polybags, BioPak, Scanlux Packaging |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |