What is Global Bulk Material Handling Conveyors Market?

The Global Bulk Material Handling Conveyors Market refers to the industry that designs, manufactures, and sells conveyor systems used to transport large quantities of materials. These systems are essential in various sectors such as mining, agriculture, construction, and more. They help in moving bulk materials like coal, grains, ores, and construction materials efficiently and safely from one place to another. The market encompasses different types of conveyors, including belt conveyors, bucket conveyors, screw conveyors, and others, each designed for specific applications and material types. The demand for these systems is driven by the need for efficient material handling solutions that can reduce labor costs, increase productivity, and ensure safety in operations. As industries continue to grow and expand, the need for advanced and reliable bulk material handling conveyors is expected to rise, making this market a crucial component of industrial operations worldwide.

Belt Conveyors, Bucket Conveyors, Screw Conveyors, Others in the Global Bulk Material Handling Conveyors Market:

Belt conveyors are one of the most common types of conveyors used in the Global Bulk Material Handling Conveyors Market. They consist of a continuous belt made of rubber, fabric, or metal that moves over rollers or a flat surface. Belt conveyors are ideal for transporting large volumes of materials over long distances and are widely used in industries like mining, agriculture, and construction. They are known for their efficiency, reliability, and ability to handle a variety of materials, from fine powders to large rocks. Bucket conveyors, on the other hand, are designed to move materials vertically. They consist of a series of buckets attached to a belt or chain that scoops up materials from a lower level and lifts them to a higher level. This type of conveyor is commonly used in industries where materials need to be transported to elevated locations, such as in grain storage facilities or cement plants. Screw conveyors are another type of bulk material handling conveyor that uses a rotating helical screw blade to move materials along a tube or trough. They are particularly effective for handling semi-solid materials, such as food waste, wood chips, and aggregates. Screw conveyors are often used in industries like agriculture and food processing, where they help in mixing and moving materials. Other types of conveyors in the market include pneumatic conveyors, which use air pressure to move materials through a pipeline, and vibrating conveyors, which use vibration to move materials along a trough. Each type of conveyor has its unique advantages and is chosen based on the specific needs of the application, the type of material being handled, and the required transportation distance.

Mining, Agriculture, Construction, Others in the Global Bulk Material Handling Conveyors Market:

The Global Bulk Material Handling Conveyors Market plays a crucial role in various industries, including mining, agriculture, construction, and others. In the mining industry, conveyors are used to transport extracted ores and minerals from the mining site to processing plants. They help in reducing the need for manual labor, increasing efficiency, and ensuring the safe transportation of heavy and bulky materials. In agriculture, conveyors are used to move grains, seeds, and other agricultural products from farms to storage facilities or processing plants. They help in streamlining the harvesting and post-harvesting processes, reducing labor costs, and minimizing product loss. In the construction industry, conveyors are used to transport construction materials like sand, gravel, and cement to different parts of the construction site. They help in speeding up the construction process, reducing manual labor, and ensuring the timely delivery of materials. Other industries that use bulk material handling conveyors include food processing, where conveyors are used to move raw materials and finished products through different stages of production, and waste management, where conveyors help in transporting waste materials to recycling or disposal facilities. The versatility and efficiency of bulk material handling conveyors make them an essential component in various industrial operations, helping to improve productivity, reduce costs, and ensure the safe and efficient transportation of materials.

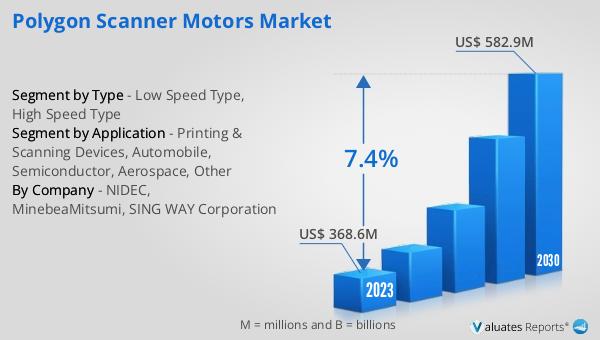

Global Bulk Material Handling Conveyors Market Outlook:

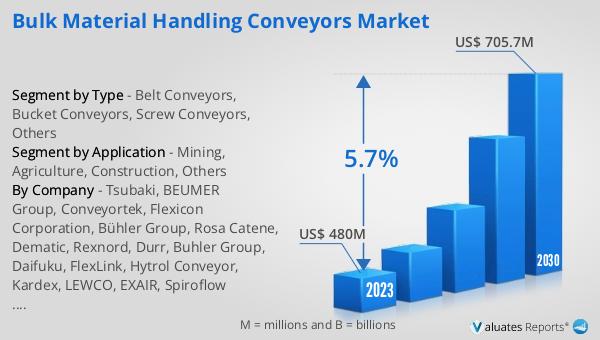

The global Bulk Material Handling Conveyors market was valued at US$ 480 million in 2023 and is anticipated to reach US$ 705.7 million by 2030, witnessing a CAGR of 5.7% during the forecast period 2024-2030. This growth can be attributed to the increasing demand for efficient material handling solutions across various industries. As industries continue to expand and modernize, the need for advanced conveyor systems that can handle large volumes of materials efficiently and safely is expected to rise. The market is also driven by technological advancements in conveyor systems, such as the development of automated and intelligent conveyors that can optimize material handling processes. Additionally, the growing focus on sustainability and the need to reduce carbon emissions in industrial operations are expected to drive the demand for energy-efficient conveyor systems. Overall, the Global Bulk Material Handling Conveyors Market is poised for significant growth in the coming years, driven by the increasing demand for efficient and reliable material handling solutions across various industries.

| Report Metric | Details |

| Report Name | Bulk Material Handling Conveyors Market |

| Accounted market size in 2023 | US$ 480 million |

| Forecasted market size in 2030 | US$ 705.7 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Tsubaki, BEUMER Group, Conveyortek, Flexicon Corporation, Bühler Group, Rosa Catene, Dematic, Rexnord, Durr, Buhler Group, Daifuku, FlexLink, Hytrol Conveyor, Kardex, LEWCO, EXAIR, Spiroflow Systems, Cablevey Conveyors, Eriez, AmbaFlex Spiral Conveyor Solutions, Macawber |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |