What is Global White Latex Deodorizer Market?

The Global White Latex Deodorizer Market refers to the industry focused on the production and distribution of white latex deodorizers. These deodorizers are specialized chemical compounds used to neutralize or mask unpleasant odors in latex products. Latex, a natural or synthetic polymer, is widely used in various industries, including medical, automotive, and consumer goods. The deodorizing agents are crucial in ensuring that latex products remain odor-free, enhancing their usability and consumer acceptance. The market encompasses a range of products, including sprays, liquids, and powders, each designed to cater to different applications and industries. The demand for white latex deodorizers is driven by the increasing use of latex in various applications and the growing awareness of the importance of maintaining product quality and hygiene. The market is characterized by continuous innovation and development of new formulations to meet the evolving needs of different industries.

Vinyl Acetate, Polyvinyl Alcohol, Dibutyl Phthalate, Octanol, Ammonium Persulfate, Others in the Global White Latex Deodorizer Market:

Vinyl Acetate, Polyvinyl Alcohol, Dibutyl Phthalate, Octanol, Ammonium Persulfate, and other chemicals play significant roles in the Global White Latex Deodorizer Market. Vinyl Acetate is a key monomer used in the production of polyvinyl acetate and polyvinyl alcohol, which are essential components in many deodorizing formulations. It provides excellent adhesion and film-forming properties, making it ideal for use in coatings and adhesives. Polyvinyl Alcohol, derived from polyvinyl acetate, is known for its high tensile strength and flexibility. It is widely used in the production of water-soluble films and as a stabilizer in emulsions, contributing to the effectiveness of deodorizing agents. Dibutyl Phthalate is a plasticizer that enhances the flexibility and durability of latex products. It is commonly used in the manufacturing of flexible plastics and rubber products, ensuring that the deodorizing agents do not compromise the physical properties of the latex. Octanol, a fatty alcohol, is used as a solvent and emulsifier in deodorizing formulations. It helps in the dispersion of active ingredients, ensuring uniform application and effectiveness. Ammonium Persulfate is an oxidizing agent used in the polymerization of latex. It helps in the formation of stable latex particles, which are essential for the production of high-quality deodorizing agents. Other chemicals used in the Global White Latex Deodorizer Market include surfactants, stabilizers, and preservatives, each contributing to the overall performance and stability of the deodorizing formulations. These chemicals are carefully selected and formulated to ensure that the deodorizing agents are effective, safe, and compatible with various latex products. The continuous research and development in the field of chemical engineering and material science play a crucial role in the advancement of the Global White Latex Deodorizer Market.

Coating, Adhesive, Others in the Global White Latex Deodorizer Market:

The Global White Latex Deodorizer Market finds extensive usage in various applications, including coatings, adhesives, and other specialized areas. In the coatings industry, white latex deodorizers are used to eliminate or mask unpleasant odors in latex-based paints and coatings. These deodorizers ensure that the final product is odor-free, enhancing the user experience and making the coatings suitable for indoor applications. The use of deodorizers in coatings also helps in maintaining the aesthetic appeal and quality of the coated surfaces. In the adhesive industry, white latex deodorizers are used to neutralize odors in latex-based adhesives. These adhesives are widely used in various applications, including packaging, construction, and automotive industries. The deodorizers ensure that the adhesives do not emit any unpleasant odors, making them more acceptable for use in sensitive applications such as food packaging and medical devices. The use of deodorizers in adhesives also helps in maintaining the integrity and performance of the adhesive bonds. In addition to coatings and adhesives, white latex deodorizers are used in other specialized applications, such as latex gloves, balloons, and rubber products. These deodorizers help in ensuring that the latex products are odor-free, enhancing their usability and consumer acceptance. The use of deodorizers in latex gloves, for example, is crucial in the medical and healthcare industry, where odor-free products are essential for maintaining hygiene and comfort. Similarly, in the consumer goods industry, odor-free latex balloons and rubber products are more appealing to consumers. The continuous innovation and development of new deodorizing formulations are essential in meeting the evolving needs of different industries and ensuring the widespread adoption of white latex deodorizers.

Global White Latex Deodorizer Market Outlook:

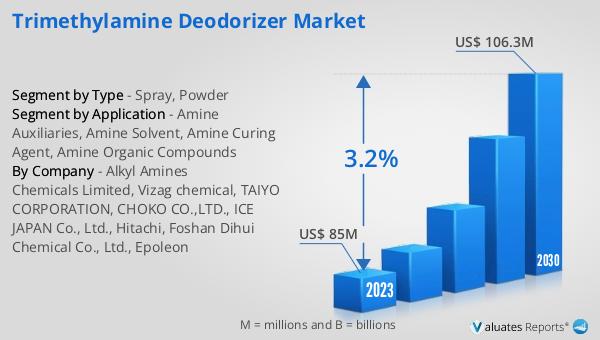

The global White Latex Deodorizer market was valued at US$ 73 million in 2023 and is anticipated to reach US$ 85 million by 2030, witnessing a CAGR of 2.4% during the forecast period 2024-2030. This market growth reflects the increasing demand for odor-neutralizing solutions in various industries that utilize latex products. The steady rise in market value indicates a growing awareness of the importance of maintaining product quality and consumer satisfaction through effective deodorizing solutions. The projected growth rate of 2.4% CAGR underscores the market's potential for expansion and the continuous innovation in deodorizing formulations. The market's valuation and growth trajectory highlight the significance of white latex deodorizers in enhancing the usability and acceptance of latex products across different applications. The anticipated increase in market value by 2030 signifies the ongoing efforts of manufacturers and researchers to develop advanced and efficient deodorizing agents that cater to the diverse needs of various industries. The market outlook emphasizes the critical role of white latex deodorizers in ensuring that latex products remain odor-free, thereby improving their overall quality and consumer appeal.

| Report Metric | Details |

| Report Name | White Latex Deodorizer Market |

| Accounted market size in 2023 | US$ 73 million |

| Forecasted market size in 2030 | US$ 85 million |

| CAGR | 2.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hollister UK, Foshan Dihui Chemical Co., Ltd., Hebei Hongyun latex recycled rubber, Ousi Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |