What is Global Automotive Microsuede Market?

The Global Automotive Microsuede Market refers to the industry focused on the production and distribution of microsuede materials specifically designed for automotive applications. Microsuede, also known as faux suede, is a synthetic fabric that mimics the texture and appearance of natural suede but offers enhanced durability, stain resistance, and ease of maintenance. This market encompasses a wide range of applications within the automotive sector, including seats, headliners, door trims, dashboards, and other interior components. The demand for microsuede in the automotive industry is driven by its luxurious feel, aesthetic appeal, and practical benefits, making it a popular choice among car manufacturers and consumers alike. As the automotive industry continues to evolve, the Global Automotive Microsuede Market is expected to grow, driven by increasing consumer preferences for high-quality, comfortable, and stylish vehicle interiors.

Seats, Headliners, Door Trims, Dashboards, Others in the Global Automotive Microsuede Market:

In the Global Automotive Microsuede Market, various components of a vehicle's interior are enhanced using microsuede materials. Seats, for instance, are one of the primary areas where microsuede is extensively used. The fabric's soft texture and luxurious feel make it an ideal choice for car seats, providing both comfort and a premium look. Additionally, microsuede is known for its durability and resistance to wear and tear, which is crucial for seats that endure constant use. Headliners, the material that covers the interior roof of a vehicle, also benefit from the use of microsuede. The fabric's lightweight nature and ability to conform to complex shapes make it suitable for headliners, offering a refined and cohesive appearance to the vehicle's interior. Door trims, which include the panels and coverings on the interior side of car doors, are another area where microsuede is commonly applied. The fabric adds a touch of elegance and sophistication to the door panels, enhancing the overall aesthetic of the vehicle. Dashboards, the control panels located in front of the driver and front passenger, can also be covered with microsuede. This application not only improves the visual appeal of the dashboard but also provides a soft and tactile surface that enhances the driving experience. Other areas where microsuede is used in the automotive industry include armrests, center consoles, and various decorative elements within the vehicle. The versatility and adaptability of microsuede make it a preferred material for a wide range of interior components, contributing to the overall comfort, style, and functionality of modern vehicles.

Sedan, SUV, Others in the Global Automotive Microsuede Market:

The usage of microsuede in the Global Automotive Microsuede Market extends to various types of vehicles, including sedans, SUVs, and others. In sedans, microsuede is often used to create a luxurious and comfortable interior environment. The fabric's soft texture and elegant appearance make it a popular choice for seat covers, headliners, and door trims in sedans, providing a premium feel that enhances the overall driving experience. Additionally, the durability and stain resistance of microsuede make it a practical option for sedan interiors, ensuring that the fabric maintains its quality and appearance over time. In SUVs, microsuede is used to create a rugged yet stylish interior. The fabric's ability to withstand heavy use and resist stains makes it ideal for SUVs, which are often used for outdoor activities and off-road adventures. Microsuede is commonly applied to seats, headliners, and door trims in SUVs, offering a combination of comfort, durability, and aesthetic appeal. The fabric's versatility also allows it to be used in various other interior components, such as armrests and center consoles, enhancing the overall functionality and style of the vehicle. In other types of vehicles, such as trucks and vans, microsuede is used to create a comfortable and practical interior environment. The fabric's durability and ease of maintenance make it suitable for vehicles that are used for commercial purposes or heavy-duty applications. Microsuede is often applied to seats, headliners, and door trims in these vehicles, providing a combination of comfort, durability, and aesthetic appeal. Overall, the usage of microsuede in the Global Automotive Microsuede Market spans a wide range of vehicle types, offering a versatile and practical solution for enhancing the interior quality and appearance of modern vehicles.

Global Automotive Microsuede Market Outlook:

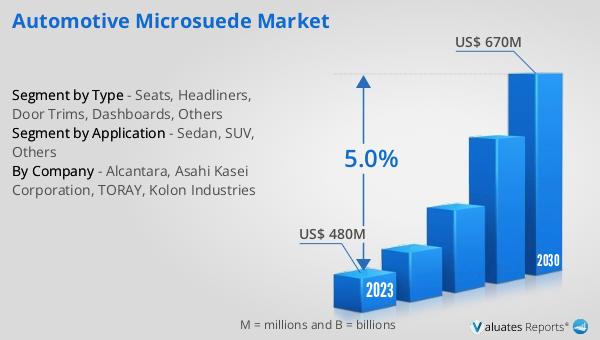

The global Automotive Microsuede market was valued at US$ 480 million in 2023 and is anticipated to reach US$ 670 million by 2030, witnessing a CAGR of 5.0% during the forecast period 2024-2030. This growth reflects the increasing demand for high-quality, durable, and aesthetically pleasing materials in the automotive industry. Microsuede, with its luxurious feel and practical benefits, has become a preferred choice for car manufacturers and consumers alike. The fabric's ability to mimic the texture and appearance of natural suede while offering enhanced durability and stain resistance makes it an ideal material for various automotive applications. As consumer preferences continue to evolve, the demand for premium and comfortable vehicle interiors is expected to drive the growth of the Global Automotive Microsuede Market. The market's expansion is also supported by advancements in manufacturing technologies and the development of new and innovative microsuede materials. Overall, the Global Automotive Microsuede Market is poised for significant growth in the coming years, driven by the increasing demand for high-quality and stylish automotive interiors.

| Report Metric | Details |

| Report Name | Automotive Microsuede Market |

| Accounted market size in 2023 | US$ 480 million |

| Forecasted market size in 2030 | US$ 670 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Alcantara, Asahi Kasei Corporation, TORAY, Kolon Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |