What is Global End Facing and Beveling Machine (EFBM) Market?

The Global End Facing and Beveling Machine (EFBM) Market is a specialized segment within the industrial machinery sector that focuses on machines designed to prepare the ends of pipes and tubes for welding or other forms of joining. These machines are essential for ensuring that the ends of pipes are smooth, properly aligned, and beveled to the correct angle, which is crucial for creating strong, reliable joints. The market encompasses a variety of machines, including both stationary and portable models, each designed to meet the specific needs of different industries such as pipeline construction, oil and gas, and power generation. The demand for EFBMs is driven by the need for precision and efficiency in pipe preparation, which in turn enhances the overall quality and durability of the final product. As industries continue to expand and modernize, the EFBM market is expected to grow, offering advanced solutions that cater to increasingly stringent quality standards and operational requirements.

Stationary Machines with Rotary Cutters, Portable Machines with Rotary Cutters in the Global End Facing and Beveling Machine (EFBM) Market:

Stationary machines with rotary cutters and portable machines with rotary cutters are two primary types of equipment within the Global End Facing and Beveling Machine (EFBM) Market. Stationary machines are typically larger and more robust, designed for high-volume, repetitive tasks in a controlled environment. These machines are often used in manufacturing plants or large-scale construction sites where precision and consistency are paramount. They are equipped with advanced features such as automated feeding systems, programmable controls, and multiple cutting heads, which allow for high-speed processing and minimal manual intervention. The rotary cutters in these machines are engineered to handle a wide range of pipe materials, including steel, stainless steel, and exotic alloys, ensuring clean, accurate cuts and bevels every time. On the other hand, portable machines with rotary cutters offer flexibility and convenience, making them ideal for on-site applications where mobility is crucial. These machines are compact, lightweight, and easy to transport, allowing operators to perform end-facing and beveling tasks in remote or confined spaces. Despite their smaller size, portable machines are built to deliver the same level of precision and efficiency as their stationary counterparts. They are equipped with powerful motors, adjustable cutting speeds, and interchangeable cutting heads, enabling them to handle various pipe diameters and wall thicknesses. Both stationary and portable machines play a vital role in the EFBM market, catering to the diverse needs of industries that require reliable and efficient pipe preparation solutions.

Pipeline Construction, Oil and Gas, Power Generation in the Global End Facing and Beveling Machine (EFBM) Market:

The usage of Global End Facing and Beveling Machine (EFBM) Market in pipeline construction, oil and gas, and power generation is extensive and multifaceted. In pipeline construction, EFBMs are indispensable for preparing the ends of pipes before they are welded together. This process ensures that the pipes fit perfectly, reducing the risk of leaks and enhancing the overall integrity of the pipeline. The precision and efficiency offered by EFBMs are crucial in large-scale pipeline projects, where even minor imperfections can lead to significant issues. In the oil and gas industry, EFBMs are used to prepare pipes for various applications, including drilling, transportation, and refining. The harsh operating conditions and stringent safety standards in this industry necessitate the use of high-quality, reliable equipment. EFBMs help ensure that the pipes used in these applications are properly prepared, reducing the risk of failures and enhancing operational efficiency. In power generation, EFBMs are used to prepare pipes for various systems, including boilers, turbines, and cooling systems. The high temperatures and pressures involved in power generation require pipes that are precisely prepared to withstand these conditions. EFBMs provide the necessary precision and consistency, ensuring that the pipes used in power generation systems are of the highest quality. Overall, the usage of EFBMs in these industries highlights their importance in ensuring the reliability, efficiency, and safety of critical infrastructure.

Global End Facing and Beveling Machine (EFBM) Market Outlook:

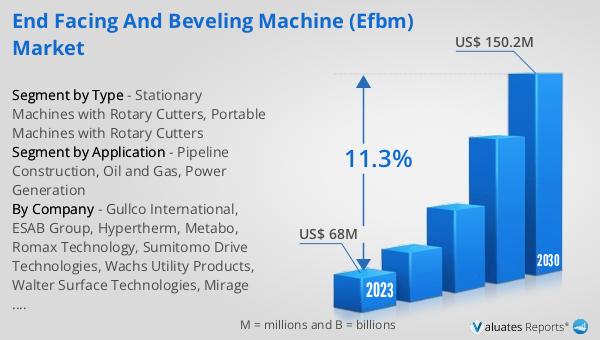

The global End Facing and Beveling Machine (EFBM) market was valued at US$ 68 million in 2023 and is anticipated to reach US$ 150.2 million by 2030, witnessing a CAGR of 11.3% during the forecast period 2024-2030. This significant growth reflects the increasing demand for precision and efficiency in pipe preparation across various industries. As industries continue to expand and modernize, the need for high-quality, reliable equipment becomes more critical. EFBMs play a crucial role in ensuring that pipes are properly prepared for welding and other forms of joining, enhancing the overall quality and durability of the final product. The market's growth is driven by advancements in technology, which have led to the development of more sophisticated and efficient machines. These advancements have enabled EFBMs to handle a wider range of materials and applications, further increasing their appeal to industries such as pipeline construction, oil and gas, and power generation. The projected growth of the EFBM market underscores the importance of these machines in maintaining the integrity and reliability of critical infrastructure.

| Report Metric | Details |

| Report Name | End Facing and Beveling Machine (EFBM) Market |

| Accounted market size in 2023 | US$ 68 million |

| Forecasted market size in 2030 | US$ 150.2 million |

| CAGR | 11.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gullco International, ESAB Group, Hypertherm, Metabo, Romax Technology, Sumitomo Drive Technologies, Wachs Utility Products, Walter Surface Technologies, Mirage Machines, Esco Tool |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |