What is Global Platform Scale Instrument Market?

The Global Platform Scale Instrument Market refers to the industry that produces and sells platform scales, which are essential tools used for weighing large and heavy items. These scales are commonly found in various sectors, including industrial, commercial, and retail environments. They are designed to provide accurate weight measurements for goods, materials, and products, ensuring efficiency and precision in operations. The market encompasses a wide range of platform scales, from small, portable models to large, heavy-duty versions capable of handling substantial weights. The demand for platform scales is driven by the need for accurate weight measurement in logistics, manufacturing, agriculture, and other industries. As businesses continue to expand globally, the requirement for reliable and efficient weighing solutions grows, making the Global Platform Scale Instrument Market a vital component of modern commerce and industry. The market is characterized by technological advancements, such as digital and wireless connectivity, which enhance the functionality and ease of use of these instruments. As a result, platform scales are becoming increasingly sophisticated, offering features like data integration and remote monitoring, which further boost their appeal across various sectors.

Static Instrument, Dynamic Instrument, Digital Instrument in the Global Platform Scale Instrument Market:

In the Global Platform Scale Instrument Market, there are three primary types of instruments: static, dynamic, and digital. Static instruments are the traditional type of platform scales that provide weight measurements when the object being weighed is stationary. These scales are widely used in industries where precise weight measurement is crucial, such as in manufacturing and packaging. Static scales are known for their durability and reliability, often constructed with robust materials to withstand heavy use. They are typically simple to operate, requiring minimal maintenance, which makes them a cost-effective choice for many businesses. However, they may not be suitable for environments where rapid weighing of moving items is necessary. Dynamic instruments, on the other hand, are designed to measure the weight of objects in motion. These scales are particularly useful in industries like logistics and transportation, where goods are constantly moving along conveyor belts or through other automated systems. Dynamic scales can quickly and accurately capture weight data without the need for items to come to a complete stop, thus enhancing efficiency and throughput. They are equipped with advanced sensors and software that can filter out noise and vibrations, ensuring precise measurements even in fast-paced environments. The ability to weigh items on the move makes dynamic instruments an invaluable asset in modern supply chains. Digital instruments represent the latest evolution in platform scale technology. These scales incorporate digital displays and electronic components to provide highly accurate and easy-to-read weight measurements. Digital scales often come with additional features such as data storage, connectivity options, and integration with other digital systems. This allows businesses to streamline their operations by automatically recording and analyzing weight data, reducing the risk of human error. Digital instruments are also more versatile, offering various modes and settings to accommodate different weighing needs. They are increasingly popular in sectors that require precise data management and reporting, such as pharmaceuticals and food processing. The integration of digital technology into platform scales has revolutionized the way businesses approach weighing tasks. With features like wireless connectivity and cloud-based data management, digital instruments enable real-time monitoring and control of weighing processes from remote locations. This capability is particularly beneficial for large-scale operations that require centralized oversight and coordination. Additionally, digital scales often come with user-friendly interfaces and customizable settings, making them accessible to operators with varying levels of technical expertise. As a result, digital instruments are becoming the preferred choice for companies looking to enhance their operational efficiency and data accuracy. Overall, the Global Platform Scale Instrument Market is characterized by a diverse range of products that cater to different industry needs. Whether it's the simplicity and reliability of static scales, the efficiency of dynamic scales, or the advanced features of digital scales, businesses have a variety of options to choose from. As technology continues to advance, the market is likely to see further innovations that will enhance the functionality and versatility of platform scales, making them even more integral to modern industrial and commercial operations.

Food Industry, Agriculture, Warehousing and Logistics Center, Others in the Global Platform Scale Instrument Market:

The Global Platform Scale Instrument Market plays a crucial role in various industries, including the food industry, agriculture, warehousing, logistics centers, and more. In the food industry, platform scales are essential for ensuring accurate weight measurements of ingredients and finished products. This is vital for maintaining quality control, adhering to regulatory standards, and optimizing production processes. Platform scales help food manufacturers achieve consistency in product weight, which is important for consumer satisfaction and compliance with labeling requirements. Additionally, these scales are used in packaging and distribution to ensure that products are correctly portioned and labeled, reducing waste and improving efficiency. In agriculture, platform scales are used to weigh crops, livestock, and other agricultural products. Accurate weight measurements are essential for determining the value of produce and livestock, as well as for managing inventory and logistics. Farmers and agricultural businesses rely on platform scales to ensure fair transactions and to optimize their operations. These scales are also used in feed mills and grain storage facilities to monitor inventory levels and to ensure that feed and grain are distributed accurately. By providing precise weight data, platform scales help agricultural businesses improve their productivity and profitability. Warehousing and logistics centers also benefit significantly from the use of platform scales. In these environments, accurate weight measurements are crucial for managing inventory, optimizing storage space, and ensuring efficient shipping and receiving processes. Platform scales help logistics companies determine the weight of packages and pallets, which is essential for calculating shipping costs and ensuring compliance with transportation regulations. By providing reliable weight data, platform scales enable logistics companies to streamline their operations, reduce errors, and improve customer satisfaction. Beyond these specific industries, platform scales are used in a variety of other applications. For example, they are employed in retail settings to weigh products for sale, ensuring that customers receive the correct amount of goods. They are also used in laboratories and research facilities to measure the weight of samples and materials with high precision. In industrial settings, platform scales are used to weigh raw materials and finished products, helping manufacturers maintain quality control and optimize production processes. The versatility and reliability of platform scales make them an indispensable tool in many different sectors, contributing to their widespread adoption and continued growth in the Global Platform Scale Instrument Market.

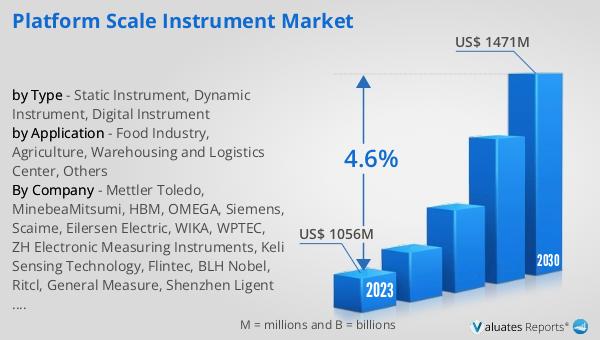

Global Platform Scale Instrument Market Outlook:

The outlook for the Global Platform Scale Instrument Market is promising, with significant growth anticipated in the coming years. In 2023, the market was valued at approximately US$ 1056 million, reflecting its importance across various industries. By 2030, it is expected to reach a value of around US$ 1471 million, driven by a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2024 to 2030. This growth can be attributed to several factors, including the increasing demand for accurate and efficient weighing solutions in industries such as logistics, manufacturing, and agriculture. As businesses continue to expand and global trade becomes more complex, the need for reliable platform scales that can handle large volumes of goods and materials is expected to rise. Additionally, technological advancements in digital and wireless connectivity are enhancing the functionality and appeal of platform scales, making them more attractive to businesses seeking to improve their operational efficiency. The market's growth is also supported by the ongoing trend towards automation and data-driven decision-making, which requires precise and reliable weight measurements. As a result, the Global Platform Scale Instrument Market is poised for continued expansion, offering opportunities for innovation and development in the coming years.

| Report Metric | Details |

| Report Name | Platform Scale Instrument Market |

| Accounted market size in 2023 | US$ 1056 million |

| Forecasted market size in 2030 | US$ 1471 million |

| CAGR | 4.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mettler Toledo, MinebeaMitsumi, HBM, OMEGA, Siemens, Scaime, Eilersen Electric, WIKA, WPTEC, ZH Electronic Measuring Instruments, Keli Sensing Technology, Flintec, BLH Nobel, Ritcl, General Measure, Shenzhen Ligent Sensor Tech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |