What is Global Pharmaceutical Extrusion Equipment Market?

The Global Pharmaceutical Extrusion Equipment Market refers to the worldwide industry focused on the production and sale of machinery used in the extrusion process within the pharmaceutical sector. Extrusion is a manufacturing process where a material is pushed through a die to create objects of a fixed cross-sectional profile. In pharmaceuticals, this process is crucial for creating various drug delivery systems, such as tablets, capsules, and implants. The equipment used in this process must meet stringent regulatory standards to ensure the safety and efficacy of the final products. The market encompasses a range of machinery, including single-screw and twin-screw extruders, each designed for specific applications and material types. The demand for pharmaceutical extrusion equipment is driven by the need for advanced drug formulations, improved bioavailability, and the development of novel drug delivery systems. As pharmaceutical companies continue to innovate and develop new therapies, the market for extrusion equipment is expected to grow, offering opportunities for manufacturers and suppliers in this specialized field.

Single Screw, Multiple Screw in the Global Pharmaceutical Extrusion Equipment Market:

Single screw and multiple screw extrusion equipment are two primary types of machinery used in the Global Pharmaceutical Extrusion Equipment Market. Single screw extruders consist of a single rotating screw within a cylindrical barrel, which pushes the material through a die to form the desired shape. These extruders are typically used for simpler, less demanding applications where the material does not require extensive mixing or complex processing. They are known for their straightforward design, ease of operation, and cost-effectiveness. Single screw extruders are often employed in the production of basic drug delivery systems, such as tablets and simple capsules, where the formulation does not require intricate processing. On the other hand, multiple screw extruders, which include twin-screw and multi-screw configurations, offer more advanced capabilities. Twin-screw extruders, for example, feature two intermeshing screws that rotate within the barrel, providing enhanced mixing, kneading, and homogenization of the material. This makes them ideal for processing complex formulations, such as those involving poorly soluble drugs or requiring precise control over the drug release profile. Multiple screw extruders are also capable of handling higher throughput rates and can accommodate a wider range of materials, including those with varying viscosities and thermal sensitivities. The versatility of multiple screw extruders makes them suitable for a broad spectrum of pharmaceutical applications, from hot melt extrusion to solid lipid extrusion. In hot melt extrusion, the material is heated to a molten state and then extruded to form solid dispersions, which can improve the bioavailability of poorly soluble drugs. Multiple screw extruders are particularly effective in this process due to their superior mixing and temperature control capabilities. Similarly, in solid lipid extrusion, the equipment is used to create lipid-based drug delivery systems, such as solid lipid nanoparticles and lipid matrices, which can enhance the stability and controlled release of active pharmaceutical ingredients. The choice between single screw and multiple screw extruders depends on various factors, including the complexity of the formulation, the desired properties of the final product, and the specific requirements of the manufacturing process. While single screw extruders offer simplicity and cost advantages, multiple screw extruders provide greater flexibility and precision, making them indispensable for advanced pharmaceutical applications. As the pharmaceutical industry continues to evolve, the demand for both types of extrusion equipment is expected to grow, driven by the need for innovative drug delivery systems and improved therapeutic outcomes.

Hot Melt Extrusion, Solid Lipid Extrusion in the Global Pharmaceutical Extrusion Equipment Market:

The Global Pharmaceutical Extrusion Equipment Market finds significant usage in areas such as hot melt extrusion and solid lipid extrusion. Hot melt extrusion (HME) is a process where a mixture of active pharmaceutical ingredients (APIs) and polymers is heated until it melts and then forced through a die to form a solid dispersion. This technique is particularly useful for enhancing the bioavailability of poorly soluble drugs. By dispersing the drug in a polymer matrix, HME can improve the dissolution rate and, consequently, the absorption of the drug in the body. The equipment used in HME must be capable of precise temperature control and efficient mixing to ensure the uniform distribution of the drug within the polymer matrix. Twin-screw extruders are often preferred for this application due to their superior mixing capabilities and ability to handle a wide range of materials. Solid lipid extrusion, on the other hand, involves the use of lipid-based materials to create drug delivery systems such as solid lipid nanoparticles (SLNs) and lipid matrices. These systems offer several advantages, including improved stability, controlled release, and enhanced bioavailability of the active pharmaceutical ingredients. The extrusion equipment used in this process must be able to handle the unique properties of lipid materials, which can vary significantly in terms of viscosity and thermal sensitivity. Multiple screw extruders are well-suited for solid lipid extrusion due to their ability to provide consistent mixing and maintain the integrity of the lipid materials throughout the process. Both hot melt extrusion and solid lipid extrusion are critical for the development of advanced drug delivery systems that can address various therapeutic challenges. For instance, hot melt extrusion is widely used in the formulation of oral solid dosage forms, such as tablets and capsules, where the goal is to achieve a uniform distribution of the drug and enhance its bioavailability. Solid lipid extrusion, on the other hand, is often employed in the development of injectable and topical formulations, where the focus is on achieving controlled release and improved stability of the drug. The versatility and efficiency of pharmaceutical extrusion equipment make it an indispensable tool in the development of these advanced drug delivery systems. As the pharmaceutical industry continues to innovate and develop new therapies, the demand for extrusion equipment in these areas is expected to grow, driven by the need for improved drug formulations and therapeutic outcomes.

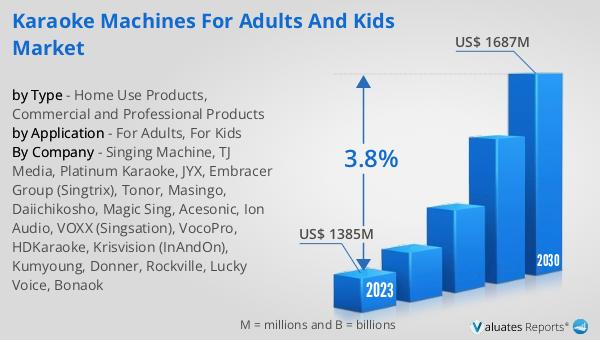

Global Pharmaceutical Extrusion Equipment Market Outlook:

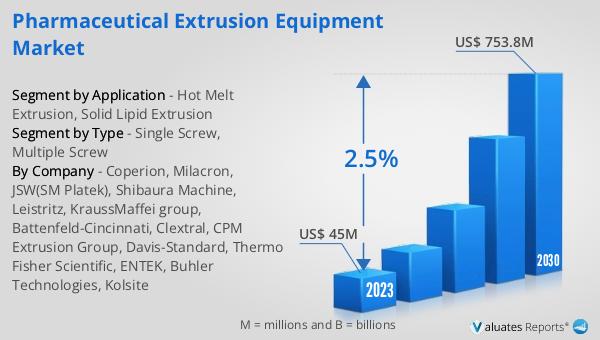

The global Pharmaceutical Extrusion Equipment market was valued at US$ 45 million in 2023 and is anticipated to reach US$ 753.8 million by 2030, witnessing a CAGR of 2.5% during the forecast period 2024-2030. This significant growth reflects the increasing demand for advanced drug delivery systems and innovative pharmaceutical formulations. The market's expansion is driven by the need for equipment that can handle complex formulations, improve bioavailability, and ensure the consistent quality of pharmaceutical products. As pharmaceutical companies continue to invest in research and development, the demand for high-quality extrusion equipment is expected to rise. This growth trajectory underscores the importance of extrusion technology in the pharmaceutical industry, highlighting its role in enhancing the efficacy and safety of drug products. The market's robust growth prospects offer opportunities for manufacturers and suppliers to innovate and meet the evolving needs of the pharmaceutical sector. With the continuous advancements in drug formulation and delivery technologies, the global Pharmaceutical Extrusion Equipment market is poised for sustained growth, driven by the ongoing pursuit of improved therapeutic outcomes and patient care.

| Report Metric | Details |

| Report Name | Pharmaceutical Extrusion Equipment Market |

| Accounted market size in 2023 | US$ 45 million |

| Forecasted market size in 2030 | US$ 753.8 million |

| CAGR | 2.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Coperion, Milacron, JSW(SM Platek), Shibaura Machine, Leistritz, KraussMaffei group, Battenfeld-Cincinnati, Clextral, CPM Extrusion Group, Davis-Standard, Thermo Fisher Scientific, ENTEK, Buhler Technologies, Kolsite |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |