What is Global Heat Resistant Labels for Power Adapter Market?

The global Heat Resistant Labels for Power Adapter market is a specialized segment within the labeling industry that focuses on providing durable and high-temperature resistant labels for power adapters. These labels are essential for ensuring that critical information, such as safety warnings, brand names, and technical specifications, remains legible and intact even under extreme heat conditions. Power adapters, which are commonly used in various electronic devices, generate heat during operation. Therefore, the labels affixed to these adapters must withstand high temperatures without degrading or losing their adhesive properties. The market for these labels is driven by the increasing demand for reliable and durable labeling solutions in the electronics industry, where safety and compliance with regulatory standards are paramount. As electronic devices become more advanced and compact, the need for heat-resistant labels that can endure higher temperatures and harsher environments continues to grow. This market encompasses various types of labels made from different substrates, each offering unique properties to meet specific application requirements.

PI Substrate, PET Substrate, Others in the Global Heat Resistant Labels for Power Adapter Market:

In the Global Heat Resistant Labels for Power Adapter Market, different substrates are used to manufacture labels that can withstand high temperatures. PI (Polyimide) Substrate is one of the most commonly used materials due to its excellent thermal stability, chemical resistance, and mechanical properties. PI Substrate labels can endure extreme temperatures, making them ideal for applications in harsh environments. These labels are often used in electronics and industrial equipment where high heat resistance is crucial. PET (Polyethylene Terephthalate) Substrate is another popular material known for its durability, flexibility, and resistance to chemicals and moisture. PET Substrate labels are suitable for applications that require moderate heat resistance and are often used in consumer electronics and medical devices. Other substrates used in the market include materials like PVC (Polyvinyl Chloride) and PP (Polypropylene), which offer varying degrees of heat resistance and are chosen based on specific application needs. PVC Substrate labels are known for their excellent electrical insulation properties and are often used in electrical and electronic applications. PP Substrate labels, on the other hand, offer good chemical resistance and are used in applications where exposure to harsh chemicals is a concern. Each substrate type has its own set of advantages and limitations, and the choice of substrate depends on factors such as the operating temperature range, environmental conditions, and the specific requirements of the application. The diversity of substrates available in the market allows manufacturers to select the most appropriate material for their labeling needs, ensuring that the labels remain intact and legible even under extreme conditions.

Electronics, Industrial Equipment, Medical, Others in the Global Heat Resistant Labels for Power Adapter Market:

The usage of Global Heat Resistant Labels for Power Adapter Market spans across various industries, including electronics, industrial equipment, medical, and others. In the electronics industry, these labels are essential for ensuring that critical information on power adapters remains legible despite the high temperatures generated during device operation. They are used to display safety warnings, brand names, and technical specifications, helping manufacturers comply with regulatory standards and enhance product safety. In industrial equipment, heat-resistant labels are used to mark components and machinery that operate in high-temperature environments. These labels provide important information such as operating instructions, safety warnings, and maintenance schedules, ensuring that the equipment is used safely and efficiently. In the medical field, heat-resistant labels are used on medical devices and equipment that are subjected to sterilization processes involving high temperatures. These labels must remain intact and legible to ensure that critical information, such as usage instructions and safety warnings, is always accessible to healthcare professionals. Other applications of heat-resistant labels include automotive, aerospace, and military industries, where equipment and components are often exposed to extreme temperatures. In these industries, the labels provide essential information for the safe and efficient operation of vehicles, aircraft, and military equipment. The versatility and durability of heat-resistant labels make them an indispensable component in various high-temperature applications, ensuring that critical information is always available and legible.

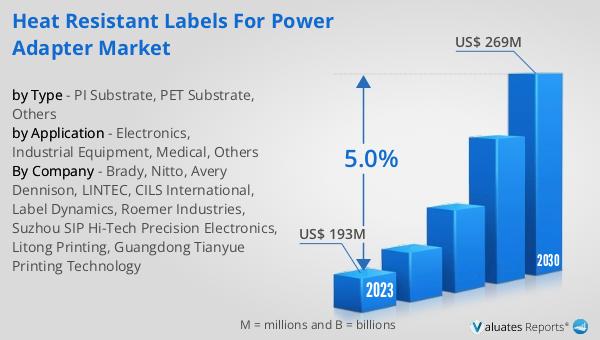

Global Heat Resistant Labels for Power Adapter Market Outlook:

The global Heat Resistant Labels for Power Adapter market was valued at US$ 193 million in 2023 and is projected to grow to US$ 269 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period from 2024 to 2030. The market is dominated by the top five players, who collectively hold a market share of over 48%. Among the different product types, PI Substrate is the largest segment, accounting for 45% of the market share. This is due to its excellent thermal stability and suitability for high-temperature applications. In terms of application, the electronics segment is the largest, with a market share of approximately 38%. This is driven by the increasing demand for reliable and durable labeling solutions in the electronics industry, where safety and compliance with regulatory standards are critical. The growth of the market is fueled by the rising demand for advanced electronic devices and the need for labels that can withstand higher temperatures and harsher environments. As the market continues to evolve, manufacturers are focusing on developing innovative labeling solutions that meet the specific requirements of various industries, ensuring that critical information remains legible and intact even under extreme conditions.

| Report Metric | Details |

| Report Name | Heat Resistant Labels for Power Adapter Market |

| Accounted market size in 2023 | US$ 193 million |

| Forecasted market size in 2030 | US$ 269 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Brady, Nitto, Avery Dennison, LINTEC, CILS International, Label Dynamics, Roemer Industries, Suzhou SIP Hi-Tech Precision Electronics, Litong Printing, Guangdong Tianyue Printing Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |