What is Global Hydrogenated Bisphenol A Market?

The global Hydrogenated Bisphenol A market is a specialized segment within the broader chemical industry. Hydrogenated Bisphenol A (HBPA) is a derivative of Bisphenol A (BPA) that has undergone hydrogenation to improve its chemical stability and performance characteristics. This compound is primarily used in the production of epoxy resins and polycarbonate plastics, which are essential materials in various industrial applications. The market for HBPA is driven by its superior properties, such as enhanced resistance to heat, chemicals, and UV radiation, making it a preferred choice in high-performance applications. The demand for HBPA is also influenced by the growing need for durable and reliable materials in sectors like electronics, automotive, and construction. As industries continue to seek advanced materials to meet stringent performance and safety standards, the global Hydrogenated Bisphenol A market is expected to witness steady growth.

Epoxy Resin-used Hydrogenated Bisphenol A, Polycarbonate-used Hydrogenated Bisphenol A, Others in the Global Hydrogenated Bisphenol A Market:

Epoxy Resin-used Hydrogenated Bisphenol A is a significant segment within the global HBPA market. Epoxy resins are widely used in various applications due to their excellent mechanical properties, chemical resistance, and strong adhesion capabilities. HBPA enhances these properties, making epoxy resins even more effective in demanding environments. These resins are commonly used in coatings, adhesives, and composite materials, which find applications in industries such as automotive, aerospace, and construction. The use of HBPA in epoxy resins ensures that the final products can withstand harsh conditions, including extreme temperatures and exposure to chemicals, thereby extending their lifespan and reliability. Polycarbonate-used Hydrogenated Bisphenol A is another crucial segment. Polycarbonates are a group of thermoplastic polymers known for their high impact resistance, transparency, and thermal stability. HBPA is used in the production of polycarbonates to improve their performance characteristics, making them suitable for applications that require durability and clarity. These materials are extensively used in the manufacturing of electronic components, optical discs, and automotive parts. The addition of HBPA to polycarbonates enhances their resistance to UV radiation and heat, ensuring that the products maintain their integrity and performance over time. Other applications of Hydrogenated Bisphenol A include its use in the production of specialty polymers and as an intermediate in chemical synthesis. These applications leverage the unique properties of HBPA to create materials that meet specific performance requirements. For instance, HBPA can be used to produce high-performance thermoplastics that are used in medical devices, consumer electronics, and industrial equipment. The versatility of HBPA makes it a valuable component in the development of advanced materials that cater to a wide range of industrial needs. Overall, the global Hydrogenated Bisphenol A market is characterized by its diverse applications and the continuous demand for high-performance materials. As industries evolve and new technologies emerge, the role of HBPA in enhancing material properties and meeting stringent performance standards will remain critical.

Electronic Packaging, Electrical Equipment Insulation Materials, Coating, Others in the Global Hydrogenated Bisphenol A Market:

The usage of Hydrogenated Bisphenol A in electronic packaging is particularly noteworthy. Electronic packaging involves the protection and insulation of electronic components to ensure their proper functioning and longevity. HBPA-based epoxy resins are widely used in this field due to their excellent electrical insulation properties, thermal stability, and resistance to environmental factors such as moisture and chemicals. These properties are crucial in preventing short circuits, protecting sensitive components, and ensuring the overall reliability of electronic devices. The use of HBPA in electronic packaging helps in maintaining the performance and safety of devices ranging from consumer electronics to industrial machinery. In the realm of electrical equipment insulation materials, HBPA plays a vital role. Electrical equipment, such as transformers, motors, and generators, requires robust insulation to prevent electrical failures and enhance operational efficiency. HBPA-based materials offer superior dielectric properties, thermal resistance, and mechanical strength, making them ideal for insulating electrical components. These materials help in reducing energy losses, preventing overheating, and extending the lifespan of electrical equipment. The reliability and efficiency of electrical systems are significantly improved with the use of HBPA-based insulation materials. Coatings are another important application area for Hydrogenated Bisphenol A. HBPA-based epoxy coatings are known for their excellent adhesion, chemical resistance, and durability. These coatings are used in various industries, including automotive, aerospace, and construction, to protect surfaces from corrosion, wear, and environmental damage. The use of HBPA in coatings ensures that the surfaces remain intact and aesthetically pleasing even under harsh conditions. For instance, in the automotive industry, HBPA-based coatings are used to protect car bodies from rust and corrosion, thereby enhancing the vehicle's lifespan and appearance. In the aerospace industry, these coatings provide protection against extreme temperatures and chemical exposure, ensuring the safety and reliability of aircraft components. Other applications of Hydrogenated Bisphenol A include its use in the production of adhesives, sealants, and composite materials. HBPA-based adhesives and sealants offer strong bonding capabilities, chemical resistance, and durability, making them suitable for various industrial and consumer applications. These products are used in the construction of buildings, manufacturing of consumer goods, and assembly of electronic devices. The versatility of HBPA allows it to be used in a wide range of applications, providing enhanced performance and reliability. In summary, the usage of Hydrogenated Bisphenol A in electronic packaging, electrical equipment insulation materials, coatings, and other applications highlights its importance in various industries. The unique properties of HBPA, such as thermal stability, chemical resistance, and mechanical strength, make it a valuable component in the development of high-performance materials. As industries continue to demand advanced materials that meet stringent performance standards, the role of HBPA in enhancing material properties and ensuring reliability will remain significant.

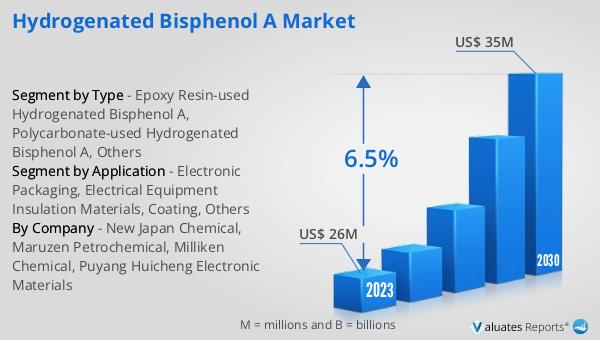

Global Hydrogenated Bisphenol A Market Outlook:

The global Hydrogenated Bisphenol A market is anticipated to expand from $24 million in 2024 to $35 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 6.5% over the forecast period. The market is dominated by the top two players, who collectively hold more than 60% of the market share. Among the different product types, Epoxy Resin-used Hydrogenated Bisphenol A is the largest segment, accounting for approximately 75% of the market. In terms of application, Electronic Packaging is the leading segment, representing about 40% of the market. This growth is driven by the increasing demand for high-performance materials in various industries, including electronics, automotive, and construction. The superior properties of Hydrogenated Bisphenol A, such as enhanced resistance to heat, chemicals, and UV radiation, make it a preferred choice for these applications. As industries continue to evolve and seek advanced materials to meet stringent performance and safety standards, the global Hydrogenated Bisphenol A market is expected to witness steady growth.

| Report Metric | Details |

| Report Name | Hydrogenated Bisphenol A Market |

| Accounted market size in 2024 | US$ 24 in million |

| Forecasted market size in 2030 | US$ 35 million |

| CAGR | 6.5 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | New Japan Chemical, Maruzen Petrochemical, Milliken Chemical, Puyang Huicheng Electronic Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |