What is Global Medical Instrument Repair Market?

The Global Medical Instrument Repair Market is a specialized sector within the broader healthcare industry that focuses on the maintenance, repair, and refurbishment of medical devices. These devices range from simple tools like stethoscopes to complex machinery such as MRI scanners and surgical robots. The market is driven by the need to ensure that medical instruments are functioning correctly and safely, which is crucial for patient care and the efficiency of healthcare services. Regular maintenance and timely repairs can extend the lifespan of these expensive instruments, reduce downtime, and ensure compliance with stringent regulatory standards. This market includes a variety of services such as fault detection, repair and upgrade, and remanufacturing, all aimed at keeping medical equipment in optimal condition. The demand for these services is growing due to the increasing complexity of medical devices, the rising number of healthcare facilities, and the need for cost-effective solutions in the healthcare sector. Companies operating in this market offer a range of services, from on-site repairs to comprehensive maintenance contracts, catering to hospitals, clinics, and other healthcare providers.

Fault Detection, Repair and Upgrade, Remanufacturing Services in the Global Medical Instrument Repair Market:

Fault detection, repair and upgrade, and remanufacturing services are critical components of the Global Medical Instrument Repair Market. Fault detection involves identifying issues in medical devices before they lead to significant malfunctions. This process often includes routine inspections, diagnostic tests, and the use of advanced software tools to monitor the performance of medical equipment. Early detection of faults can prevent costly repairs and ensure that devices are always ready for use. Repair and upgrade services focus on fixing identified issues and enhancing the functionality of medical instruments. Repairs can range from simple fixes, like replacing worn-out parts, to more complex procedures, such as recalibrating sensitive equipment. Upgrades, on the other hand, involve updating the software or hardware components of medical devices to improve their performance or add new features. This is particularly important in a field where technological advancements are frequent, and staying up-to-date can significantly impact the quality of patient care. Remanufacturing services take this a step further by completely overhauling used medical devices to restore them to like-new condition. This process includes disassembling the equipment, cleaning and replacing worn parts, and reassembling and testing the device to ensure it meets original specifications. Remanufacturing not only extends the life of medical instruments but also offers a cost-effective alternative to purchasing new equipment. These services are essential for maintaining the reliability and efficiency of medical devices, which are critical for accurate diagnostics and effective treatments. Companies offering these services often provide comprehensive maintenance contracts that include regular inspections, emergency repairs, and upgrades, ensuring that healthcare providers can focus on patient care without worrying about equipment downtime. The growing complexity of medical devices and the increasing pressure on healthcare facilities to reduce costs are driving the demand for these services. By ensuring that medical instruments are always in optimal condition, these services play a crucial role in the overall healthcare delivery system.

Hospital, Clinic in the Global Medical Instrument Repair Market:

The usage of the Global Medical Instrument Repair Market is particularly significant in hospitals and clinics, where the reliability and accuracy of medical devices are paramount. In hospitals, a wide range of medical instruments is used daily, from diagnostic tools like X-ray machines and CT scanners to therapeutic devices such as ventilators and infusion pumps. The high volume of patients and the critical nature of the services provided mean that any equipment malfunction can have serious consequences. Regular maintenance and timely repairs are essential to ensure that these devices are always ready for use. Hospitals often enter into maintenance contracts with specialized companies to handle the upkeep of their medical equipment. These contracts typically include routine inspections, preventive maintenance, and emergency repair services, ensuring minimal downtime and uninterrupted patient care. In clinics, the range of medical instruments may be smaller, but their importance is no less significant. Clinics often rely on diagnostic tools like ultrasound machines, ECG monitors, and blood analyzers to provide accurate and timely diagnoses. Any malfunction in these devices can delay diagnosis and treatment, affecting patient outcomes. Like hospitals, clinics also benefit from regular maintenance and repair services to keep their equipment in optimal condition. Additionally, clinics may opt for remanufactured devices as a cost-effective alternative to purchasing new equipment, especially when budget constraints are a concern. The Global Medical Instrument Repair Market provides a vital service to both hospitals and clinics by ensuring that their medical devices are always functioning correctly and safely. This not only enhances the quality of patient care but also helps healthcare providers manage their operational costs more effectively. By extending the lifespan of medical instruments and reducing the need for frequent replacements, these services contribute to the overall efficiency and sustainability of healthcare facilities.

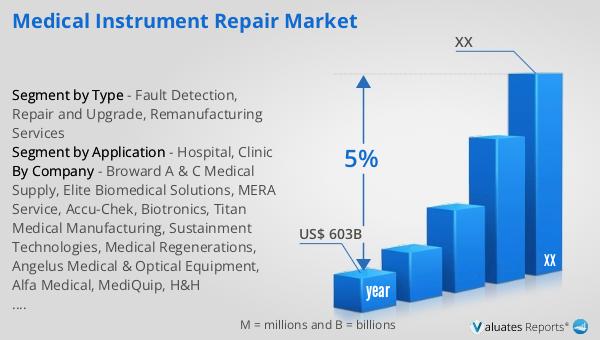

Global Medical Instrument Repair Market Outlook:

According to our research, the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including technological advancements in medical devices, increasing healthcare expenditure, and the rising prevalence of chronic diseases. The demand for medical devices is also fueled by the growing aging population, which requires more frequent medical interventions and monitoring. As the market expands, the need for reliable and efficient medical instrument repair services becomes even more critical. Ensuring that medical devices are always in optimal condition is essential for maintaining the quality of patient care and the efficiency of healthcare services. Companies operating in the Global Medical Instrument Repair Market are well-positioned to capitalize on this growth by offering a range of services that cater to the diverse needs of healthcare providers. From routine maintenance and fault detection to comprehensive repair and remanufacturing services, these companies play a crucial role in supporting the healthcare industry. By keeping medical instruments in top condition, they help healthcare providers deliver better patient outcomes and manage their operational costs more effectively.

| Report Metric | Details |

| Report Name | Medical Instrument Repair Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Broward A & C Medical Supply, Elite Biomedical Solutions, MERA Service, Accu-Chek, Biotronics, Titan Medical Manufacturing, Sustainment Technologies, Medical Regenerations, Angelus Medical & Optical Equipment, Alfa Medical, MediQuip, H&H Environmental Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |