What is Global Marine Flexible Mechanical Couplings Market?

The global Marine Flexible Mechanical Couplings market is a specialized segment within the broader marine industry, focusing on the development and distribution of flexible mechanical couplings used in marine applications. These couplings are essential components that connect two shafts together, allowing for the transmission of power while accommodating misalignment and reducing vibration and noise. They are crucial in ensuring the smooth operation of marine vessels, including ships, boats, and submarines. The market encompasses a variety of coupling types, each designed to meet specific performance requirements and environmental conditions. The demand for these couplings is driven by the need for reliable and efficient power transmission systems in marine vessels, which are subject to harsh operating conditions and require high levels of durability and performance. The market is characterized by a mix of established manufacturers and innovative newcomers, all striving to provide advanced solutions that enhance the operational efficiency and longevity of marine vessels. As the marine industry continues to evolve, the demand for flexible mechanical couplings is expected to grow, driven by advancements in marine technology and the increasing complexity of marine propulsion systems.

Flanged, Clamped, Other in the Global Marine Flexible Mechanical Couplings Market:

In the Global Marine Flexible Mechanical Couplings Market, there are several types of couplings, including flanged, clamped, and other variations, each serving distinct purposes and offering unique benefits. Flanged couplings are widely used due to their robust design and ability to handle high torque and axial loads. They consist of two flanges that are bolted together, providing a secure and rigid connection. This type of coupling is particularly suitable for applications where precise alignment is crucial, and it is commonly found in larger marine vessels where reliability and strength are paramount. Clamped couplings, on the other hand, offer a more flexible solution. They use a clamping mechanism to connect the shafts, allowing for easier installation and removal. This type of coupling is ideal for applications where frequent maintenance or adjustments are required, as it can be quickly disassembled and reassembled without the need for specialized tools. Clamped couplings are often used in smaller vessels or in situations where space is limited and ease of access is important. Other types of couplings in the market include elastomeric, gear, and grid couplings, each offering specific advantages depending on the application. Elastomeric couplings, for example, use an elastic material to absorb shock and vibration, making them suitable for applications where noise reduction and smooth operation are critical. Gear couplings, with their high torque capacity and ability to accommodate misalignment, are often used in heavy-duty applications. Grid couplings, which use a grid structure to transmit torque, offer a balance between flexibility and strength, making them suitable for a wide range of marine applications. The choice of coupling type depends on various factors, including the size and type of vessel, the operating conditions, and the specific performance requirements. Manufacturers in the market are continually innovating to develop couplings that offer improved performance, durability, and ease of maintenance, ensuring that they meet the evolving needs of the marine industry.

Monohull, Multihull, Others in the Global Marine Flexible Mechanical Couplings Market:

The usage of Global Marine Flexible Mechanical Couplings Market in different types of vessels, such as monohull, multihull, and others, highlights the versatility and importance of these components in marine applications. In monohull vessels, which are characterized by a single hull, flexible mechanical couplings play a crucial role in ensuring smooth and efficient power transmission. These vessels, which include a wide range of ships and boats, rely on couplings to connect the engine to the propeller shaft, allowing for the transfer of power while accommodating misalignment and reducing vibration. This is particularly important in monohull vessels, where the alignment of the propulsion system can be affected by the movement of the hull in the water. Flexible couplings help to absorb these movements, ensuring that the propulsion system operates smoothly and efficiently. In multihull vessels, which have two or more hulls, the role of flexible mechanical couplings is equally important. These vessels, which include catamarans and trimarans, often have more complex propulsion systems, with multiple engines and propeller shafts. Flexible couplings are used to connect these components, allowing for the efficient transfer of power while accommodating the unique alignment challenges posed by the multiple hulls. The ability of flexible couplings to absorb shock and vibration is particularly beneficial in multihull vessels, where the movement of the hulls can create additional stresses on the propulsion system. In addition to monohull and multihull vessels, flexible mechanical couplings are also used in a variety of other marine applications, including submarines, offshore platforms, and marine renewable energy systems. In submarines, for example, flexible couplings are used to connect the propulsion system to the propeller shaft, allowing for the efficient transfer of power while accommodating the unique alignment challenges posed by the underwater environment. In offshore platforms, flexible couplings are used to connect various components of the power transmission system, ensuring that the platform operates smoothly and efficiently. In marine renewable energy systems, such as tidal and wave energy converters, flexible couplings are used to connect the energy capture devices to the power transmission system, allowing for the efficient transfer of power while accommodating the unique alignment challenges posed by the marine environment. Overall, the usage of flexible mechanical couplings in these various applications highlights their importance in ensuring the smooth and efficient operation of marine vessels and systems.

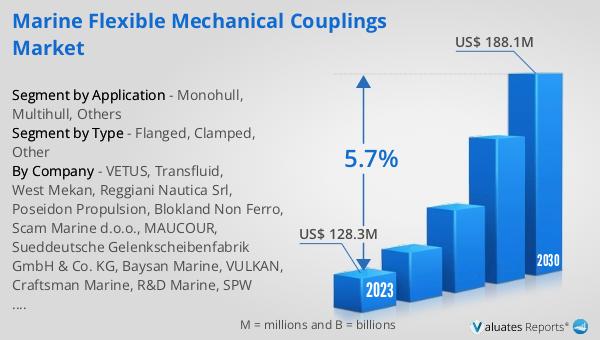

Global Marine Flexible Mechanical Couplings Market Outlook:

The global Marine Flexible Mechanical Couplings market was valued at US$ 128.3 million in 2023 and is anticipated to reach US$ 188.1 million by 2030, witnessing a CAGR of 5.7% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for reliable and efficient power transmission systems in marine vessels. The projected growth reflects the ongoing advancements in marine technology and the need for components that can withstand the harsh operating conditions of the marine environment. The market's valuation in 2023 underscores the significant role that flexible mechanical couplings play in the marine industry, providing essential solutions for power transmission and vibration reduction. As the market continues to grow, manufacturers are expected to focus on innovation and the development of advanced coupling solutions that meet the evolving needs of the marine industry. The anticipated growth to US$ 188.1 million by 2030 highlights the potential for continued investment and development in this market segment, driven by the increasing complexity of marine propulsion systems and the need for durable and high-performance components. The CAGR of 5.7% during the forecast period further emphasizes the steady demand for flexible mechanical couplings, reflecting the ongoing importance of these components in ensuring the smooth and efficient operation of marine vessels.

| Report Metric | Details |

| Report Name | Marine Flexible Mechanical Couplings Market |

| Accounted market size in 2023 | US$ 128.3 million |

| Forecasted market size in 2030 | US$ 188.1 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | VETUS, Transfluid, West Mekan, Reggiani Nautica Srl, Poseidon Propulsion, Blokland Non Ferro, Scam Marine d.o.o., MAUCOUR, Sueddeutsche Gelenkscheibenfabrik GmbH & Co. KG, Baysan Marine, VULKAN, Craftsman Marine, R&D Marine, SPW GmbH, jbj Techniques |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |