What is Global IC Substrate Drill Market?

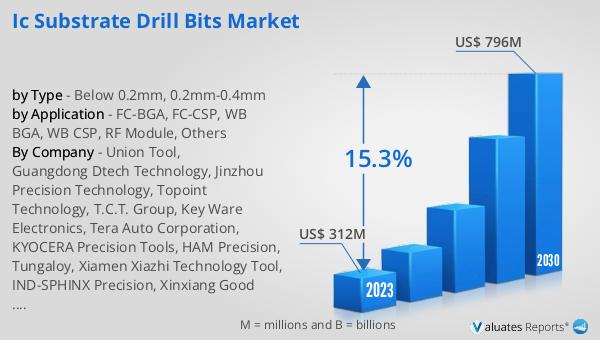

The Global IC Substrate Drill Market is a specialized sector within the electronics manufacturing industry, focusing on the production of drilled substrates that are essential components in integrated circuits (ICs). These substrates serve as the foundation upon which semiconductor materials are deposited and patterned to create the intricate networks that form ICs. The drilling process is critical as it allows for the creation of vias or holes, which are necessary for electrical connections between the different layers of the IC. As technology advances, the demand for smaller, more efficient, and higher performing electronic devices grows, driving the need for more precise and accurately drilled substrates. This market's significance lies in its direct impact on the overall performance and capabilities of electronic devices, ranging from smartphones to advanced computing systems. With a valuation of US$ 312 million in 2023, the market is on a trajectory to expand to US$ 796 million by 2030, propelled by a compound annual growth rate (CAGR) of 15.3% over the forecast period from 2024 to 2030. This growth is indicative of the increasing importance of high-quality IC substrates in the ever-evolving electronics industry.

Below 0.2mm, 0.2mm-0.4mm in the Global IC Substrate Drill Market:

Diving into the specifics of the Global IC Substrate Drill Market, the segmentation based on drill bit sizes, specifically below 0.2mm and 0.2mm-0.4mm, reveals the market's nuanced dynamics. Drills below 0.2mm are at the forefront of miniaturization in electronics, catering to the production of ultra-compact IC substrates required for high-density and high-performance devices. These tiny drills allow for the creation of micro-vias that are essential in achieving the multi-layered connectivity needed in advanced ICs, such as those used in smartphones, wearable technology, and medical devices. On the other hand, drills sized between 0.2mm and 0.4mm cater to a slightly different segment of the market. These drills are typically used for applications that require a balance between performance and cost-effectiveness, making them suitable for a wide range of consumer electronics and automotive applications. The precision and reliability of these drills ensure that they remain a critical component in the manufacturing of IC substrates that meet the diverse needs of the global electronics market. The distinction between these two segments underscores the market's ability to cater to the broad spectrum of technological requirements, from the most advanced to the more standard applications, highlighting the industry's adaptability and technological prowess.

FC-BGA, FC-CSP, WB BGA, WB CSP, RF Module, Others in the Global IC Substrate Drill Market:

The usage of the Global IC Substrate Drill Market spans several key areas, including FC-BGA, FC-CSP, WB BGA, WB CSP, RF Module, and others, each serving distinct functions in the electronics manufacturing ecosystem. FC-BGA (Flip Chip-Ball Grid Array) and FC-CSP (Flip Chip-Chip Scale Package) represent high-performance applications where the precision of drilled substrates is paramount. These technologies enable more efficient electrical connections and heat dissipation, which are critical for the functionality of CPUs, GPUs, and memory modules in computing and gaming devices. Similarly, WB BGA (Wire Bond-Ball Grid Array) and WB CSP (Wire Bond-Chip Scale Package) rely on the accuracy of drilled substrates to ensure reliable wire bonding connections, essential for a wide range of consumer electronics. The RF Module segment, which includes components for wireless communication, demands high precision in drilling to maintain signal integrity and performance. The "Others" category encompasses a variety of applications, including sensors and actuators, highlighting the market's versatility. The broad applicability of IC substrate drills underscores their critical role in enabling the functionality and reliability of modern electronic devices, from everyday gadgets to sophisticated industrial equipment.

Global IC Substrate Drill Market Outlook:

The market outlook for the Global IC Substrate Drill Market reflects a robust growth trajectory, with its valuation set to expand significantly from US$ 312 million in 2023 to an estimated US$ 796 million by 2030. This growth, characterized by a compound annual growth rate (CAGR) of 15.3% during the forecast period from 2024 to 2030, underscores the market's dynamic nature and its critical role in the broader electronics manufacturing industry. This expansion is driven by the escalating demand for more sophisticated and high-performance electronic devices, which in turn necessitates advancements in IC substrate drilling technology. The precision and efficiency of these drills are paramount in enabling the production of the next generation of integrated circuits, which are the backbone of modern electronics. As devices become smaller, faster, and more capable, the importance of the IC Substrate Drill Market continues to rise, reflecting its pivotal position in meeting the technological needs of the future.

| Report Metric | Details |

| Report Name | IC Substrate Drill Market |

| Accounted market size in 2023 | US$ 312 million |

| Forecasted market size in 2030 | US$ 796 million |

| CAGR | 15.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Union Tool, Guangdong Dtech Technology, Jinzhou Precision Technology, Topoint Technology, T.C.T. Group, Key Ware Electronics, Tera Auto Corporation, KYOCERA Precision Tools, HAM Precision, Tungaloy, Xiamen Xiazhi Technology Tool, IND-SPHINX Precision, Xinxiang Good Team Electronics, Longnan Huaying Precision |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |