What is Global Safety Class Nuclear Pumps Market?

The Global Safety Class Nuclear Pumps Market refers to a specialized segment within the nuclear industry, focusing on the production and distribution of pumps that are critical for the safety systems of nuclear reactors. These pumps are designed to meet stringent safety standards to ensure the reliable operation of nuclear power plants, especially under emergency conditions. They play a crucial role in cooling the reactor core, managing the flow of nuclear coolant, and in the containment and control of radioactive substances. The market for these safety-class pumps is driven by the need for nuclear energy to meet global electricity demands while adhering to international safety protocols. As countries continue to invest in nuclear power as a means to diversify their energy sources and reduce carbon emissions, the demand for these specialized pumps is expected to grow. This segment is highly regulated due to the critical nature of its application, ensuring that only the highest quality and reliability standards are met to maintain the safety and efficiency of nuclear power operations.

Class 1 Pumps, Class 2 and 3 Pumps in the Global Safety Class Nuclear Pumps Market:

In the realm of the Global Safety Class Nuclear Pumps Market, pumps are categorized into three main classes based on their safety significance and application within a nuclear power plant: Class 1, Class 2, and Class 3. Class 1 pumps are considered the most critical, as they are directly involved in the cooling of the nuclear reactor core and the containment of radioactive materials. These pumps must operate under extreme conditions, including high temperatures and pressures, and are designed to withstand seismic events and other emergency scenarios without failure. Class 2 pumps, while still important for safety, are used in systems that support the primary cooling systems and other safety-related functions but are not directly cooling the reactor core. These pumps may handle less severe conditions compared to Class 1 pumps but still require a high level of reliability and durability. Class 3 pumps are involved in systems that are not directly related to the cooling of the reactor core but are necessary for the safe operation of the plant, such as fire protection and component cooling water systems. Although these pumps are considered the least critical in terms of direct safety impact, their failure could still compromise the plant's safety systems indirectly. Each class of pump is subject to rigorous testing and certification processes to ensure they meet the specific safety standards required for their respective roles within a nuclear power plant.

Reactor, Other Equipment in the Global Safety Class Nuclear Pumps Market:

The Global Safety Class Nuclear Pumps Market finds its applications primarily in two critical areas within nuclear power plants: the reactor and other equipment. In the reactor, these pumps are indispensable for the circulation of coolant, which is essential for removing heat from the reactor core and preventing overheating. This cooling function is critical not only during normal operations but also in the event of an emergency, where the ability to cool the reactor core rapidly can prevent a meltdown. The reliability and efficiency of these pumps directly impact the safety and operational stability of the nuclear reactor, highlighting their importance in the nuclear energy sector. Beyond the reactor, safety class nuclear pumps are also used in various other equipment and systems within a nuclear power plant. This includes, but is not limited to, emergency cooling systems, waste treatment systems, and the circulation of cooling water for other critical components. Each application demands pumps that can operate under specific conditions, including handling radioactive materials or operating in potentially harsh environments. The design and operation of these pumps ensure that they can maintain their functionality and integrity, even under challenging conditions, thereby supporting the overall safety systems of the nuclear power plant.

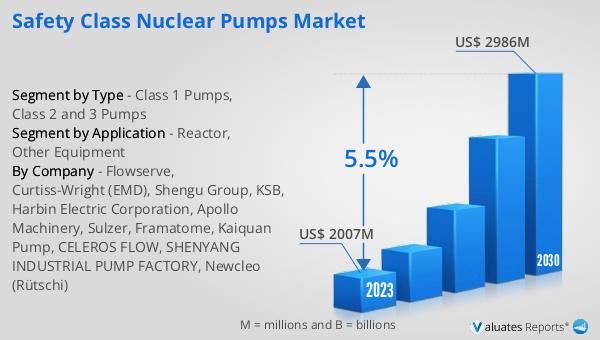

Global Safety Class Nuclear Pumps Market Outlook:

The market outlook for the Global Safety Class Nuclear Pumps Market presents a promising future, with its value estimated at US$ 2007 million in 2023. This figure is expected to climb to US$ 2986 million by the year 2030, marking a Compound Annual Growth Rate (CAGR) of 5.5% throughout the forecast period spanning from 2024 to 2030. This growth trajectory underscores the increasing reliance on nuclear energy across the globe and the critical role that safety class nuclear pumps play in ensuring the operational integrity and safety of nuclear power plants. As the demand for clean, reliable, and efficient energy sources continues to rise, the nuclear sector is poised for expansion, driving the need for high-quality, dependable safety class nuclear pumps. This market growth is reflective of the broader trends in energy production, where safety and sustainability are becoming paramount concerns. The anticipated increase in market value highlights the importance of continuous innovation and stringent safety standards in the production of nuclear pumps, ensuring they can meet the evolving demands of the nuclear energy industry.

| Report Metric | Details |

| Report Name | Safety Class Nuclear Pumps Market |

| Accounted market size in 2023 | US$ 2007 million |

| Forecasted market size in 2030 | US$ 2986 million |

| CAGR | 5.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Flowserve, Curtiss-Wright (EMD), Shengu Group, KSB, Harbin Electric Corporation, Apollo Machinery, Sulzer, Framatome, Kaiquan Pump, CELEROS FLOW, SHENYANG INDUSTRIAL PUMP FACTORY, Newcleo (Rütschi) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |