What is Global Pharmaceutical Freeze Dryer Market?

The Global Pharmaceutical Freeze Dryer Market is a specialized segment within the pharmaceutical industry, focusing on the technology and equipment used to lyophilize (freeze-dry) pharmaceutical products. This process is crucial for preserving the stability, potency, and shelf life of various pharmaceuticals, especially those that are biologically based, such as vaccines, antibodies, and other biologics. By removing water from the product under low temperature and vacuum, freeze dryers ensure that these sensitive compounds remain effective and safe for use over extended periods. This market caters to the growing demand for advanced preservation methods as the pharmaceutical industry evolves and expands its range of products. With the increasing complexity of drugs and the global push for more accessible healthcare, the role of freeze drying technology has become more significant, driving advancements and investments in this area. The market encompasses a range of equipment sizes and capabilities, from small laboratory units to large industrial systems, designed to meet the diverse needs of pharmaceutical manufacturers around the world.

Fully Automatic, Semi-automatic in the Global Pharmaceutical Freeze Dryer Market:

Diving into the Global Pharmaceutical Freeze Dryer Market, we find it segmented into fully automatic and semi-automatic freeze dryers, each catering to different needs within the pharmaceutical industry. Fully automatic freeze dryers represent the pinnacle of convenience and efficiency. These systems are designed to handle the entire lyophilization process with minimal human intervention, from freezing the product, applying a vacuum, and then gradually warming it up to remove all moisture content. This automation ensures a consistent and reproducible drying process, which is crucial for maintaining the quality and efficacy of pharmaceutical products. On the other hand, semi-automatic freeze dryers offer a balance between automation and manual control, allowing operators to adjust certain parameters during the freeze-drying process. This can be particularly useful for research and development purposes or for processing sensitive products that require a more hands-on approach. Both types of freeze dryers play vital roles in the pharmaceutical industry, from the production of small batches for clinical trials to large-scale manufacturing of commercial drugs. The choice between fully automatic and semi-automatic systems depends on various factors, including the scale of production, the nature of the pharmaceutical products, and the specific requirements of the manufacturing process.

Industrial, Laboratory, Others in the Global Pharmaceutical Freeze Dryer Market:

The usage of the Global Pharmaceutical Freeze Dryer Market spans across industrial, laboratory, and other applications, each serving a unique purpose in the pharmaceutical and biotechnology fields. In industrial settings, freeze dryers are employed on a large scale to ensure the stability and longevity of pharmaceutical products before they reach consumers. This involves processing vast quantities of drugs, vaccines, and other biological materials, making it essential for these units to be highly efficient and capable of handling extensive batches. Laboratories, on the other hand, utilize smaller freeze dryers for research and development purposes. These units are crucial for experimenting with new formulations, determining optimal lyophilization cycles, and ensuring that products can be scaled up for industrial production without losing their efficacy. The "others" category encompasses a variety of specialized applications, such as freeze-drying of nutraceuticals, cosmeceuticals, and even pet pharmaceuticals. Each of these areas relies on the precise control and consistent performance of freeze dryers to produce high-quality, stable products that meet stringent regulatory standards. The versatility and adaptability of freeze drying technology make it indispensable across the spectrum of pharmaceutical manufacturing and research.

Global Pharmaceutical Freeze Dryer Market Outlook:

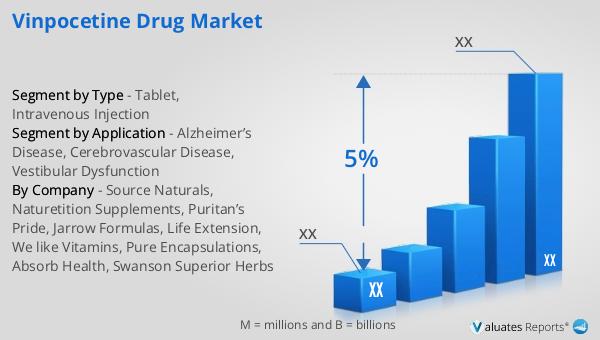

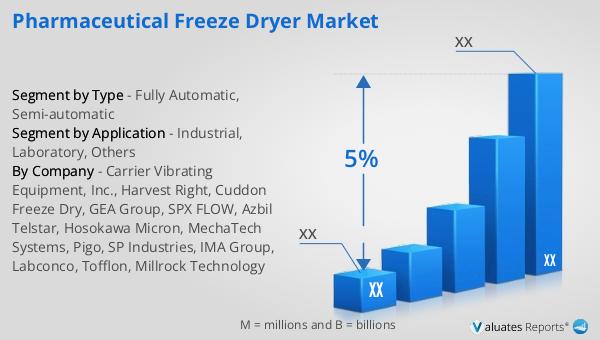

In 2022, the global pharmaceutical market reached a milestone, boasting a value of 1475 billion USD, with projections indicating a steady growth rate of 5% over the following six years. This growth trajectory highlights the dynamic nature of the pharmaceutical industry and its critical role in global healthcare. In contrast, the chemical drug sector, a significant component of the broader market, has also seen substantial growth. Starting from a base of 1005 billion USD in 2018, it is estimated to have climbed to 1094 billion USD by 2022. These figures underscore the continuous expansion and evolution of the pharmaceutical industry, driven by relentless innovation, increasing healthcare demands, and the ongoing development of new drugs and therapies. The sustained growth in both the overall pharmaceutical market and the chemical drug niche reflects the industry's resilience and its pivotal position in addressing the health challenges of a growing global population.

| Report Metric | Details |

| Report Name | Pharmaceutical Freeze Dryer Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Carrier Vibrating Equipment, Inc., Harvest Right, Cuddon Freeze Dry, GEA Group, SPX FLOW, Azbil Telstar, Hosokawa Micron, MechaTech Systems, Pigo, SP Industries, IMA Group, Labconco, Tofflon, Millrock Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |