What is Global Fiber Reinforced Polymer (FRP) Rebars Market?

Global Fiber Reinforced Polymer (FRP) Rebars Market is a rapidly evolving segment within the construction industry, driven by the increasing demand for durable and corrosion-resistant materials. FRP rebars are composite materials made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. These materials are gaining popularity due to their superior properties compared to traditional steel rebars, such as high strength-to-weight ratio, resistance to corrosion, and ease of installation. The market is witnessing significant growth as industries seek sustainable and long-lasting solutions for infrastructure development. The adoption of FRP rebars is particularly prominent in regions with harsh environmental conditions, where traditional materials may fail over time. As the construction industry continues to evolve, the demand for innovative materials like FRP rebars is expected to rise, offering new opportunities for manufacturers and suppliers in the market. The global market for FRP rebars is characterized by a diverse range of applications, from bridges and highways to marine structures and water treatment plants, highlighting the versatility and adaptability of these advanced materials. As awareness of the benefits of FRP rebars grows, the market is poised for continued expansion, driven by technological advancements and increasing investment in infrastructure projects worldwide.

Vinyl Ester, Polyester, Others in the Global Fiber Reinforced Polymer (FRP) Rebars Market:

Vinyl ester, polyester, and other resins play a crucial role in the Global Fiber Reinforced Polymer (FRP) Rebars Market, each offering unique properties that cater to specific applications and requirements. Vinyl ester resins are known for their excellent corrosion resistance, making them ideal for use in environments exposed to harsh chemicals and moisture. This property makes vinyl ester-based FRP rebars particularly suitable for applications in marine structures, chemical plants, and wastewater treatment facilities, where exposure to corrosive elements is a significant concern. Additionally, vinyl ester resins offer good mechanical properties and thermal stability, ensuring the durability and longevity of the structures they reinforce. Polyester resins, on the other hand, are widely used in the FRP rebars market due to their cost-effectiveness and versatility. While they may not offer the same level of corrosion resistance as vinyl ester resins, polyester-based FRP rebars are still suitable for a wide range of applications, including residential and commercial construction, where the exposure to corrosive elements is less severe. The affordability of polyester resins makes them an attractive option for projects with budget constraints, allowing for the widespread adoption of FRP technology in various construction sectors. Other resins, such as epoxy and phenolic, also contribute to the diversity of the FRP rebars market. Epoxy resins are known for their exceptional mechanical properties and adhesion, making them suitable for high-performance applications where strength and durability are paramount. Phenolic resins, on the other hand, offer excellent fire resistance and low smoke emission, making them ideal for use in applications where fire safety is a critical concern. The choice of resin in FRP rebars depends on several factors, including the specific requirements of the application, environmental conditions, and budget considerations. Manufacturers in the FRP rebars market continue to innovate and develop new resin formulations to enhance the performance and expand the range of applications for these advanced materials. As the demand for sustainable and durable construction materials grows, the role of resins in the FRP rebars market becomes increasingly important, driving further research and development in this field. The ongoing advancements in resin technology are expected to contribute to the continued growth and diversification of the FRP rebars market, offering new opportunities for manufacturers and end-users alike. By understanding the unique properties and applications of different resins, stakeholders in the FRP rebars market can make informed decisions and optimize the performance of their construction projects.

Marine Structures & Waterfronts, Highways Bridges & Buildings, Water Treatment Plants, MRI Rooms, Others in the Global Fiber Reinforced Polymer (FRP) Rebars Market:

The usage of Global Fiber Reinforced Polymer (FRP) Rebars Market in various sectors highlights the versatility and adaptability of these advanced materials. In marine structures and waterfronts, FRP rebars are increasingly used due to their excellent resistance to corrosion and harsh environmental conditions. Traditional steel rebars are prone to rust and degradation when exposed to saltwater and marine environments, leading to costly repairs and maintenance. FRP rebars, with their non-corrosive properties, offer a long-lasting and cost-effective solution for reinforcing marine structures such as piers, docks, and seawalls. In highways, bridges, and buildings, FRP rebars provide a lightweight yet strong alternative to steel, reducing the overall weight of the structures and enhancing their load-bearing capacity. The use of FRP rebars in these applications not only extends the lifespan of the infrastructure but also reduces maintenance costs and improves safety. Water treatment plants benefit from the use of FRP rebars due to their resistance to chemicals and moisture, ensuring the structural integrity of the facilities over time. The non-conductive nature of FRP rebars also makes them suitable for use in MRI rooms, where electromagnetic interference must be minimized. In addition to these specific applications, FRP rebars are also used in a variety of other sectors, including industrial facilities, power plants, and transportation infrastructure. The growing awareness of the benefits of FRP rebars, coupled with advancements in manufacturing technology, is driving their adoption across a wide range of industries. As the demand for sustainable and durable construction materials continues to rise, the use of FRP rebars is expected to expand further, offering new opportunities for innovation and growth in the market. The versatility of FRP rebars allows them to be tailored to meet the specific needs of different applications, ensuring optimal performance and longevity. By leveraging the unique properties of FRP rebars, industries can enhance the durability and sustainability of their infrastructure, contributing to a more resilient and efficient built environment.

Global Fiber Reinforced Polymer (FRP) Rebars Market Outlook:

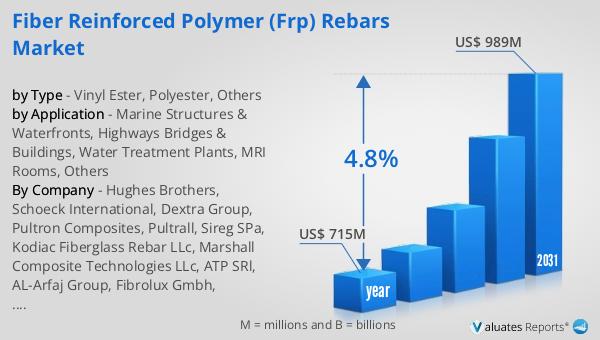

The global market for Fiber Reinforced Polymer (FRP) Rebars was valued at approximately $715 million in 2024. This market is anticipated to grow significantly, reaching an estimated size of $989 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.8% over the forecast period. The increasing demand for durable and corrosion-resistant construction materials is a key driver of this market expansion. As industries and governments worldwide invest in infrastructure development, the need for innovative materials like FRP rebars is becoming more pronounced. These materials offer a sustainable and long-lasting alternative to traditional steel rebars, which are prone to corrosion and degradation over time. The projected growth of the FRP rebars market reflects the growing awareness and adoption of these advanced materials across various sectors, including construction, marine, and industrial applications. As the market continues to evolve, manufacturers and suppliers are expected to capitalize on the opportunities presented by the increasing demand for FRP rebars, driving further innovation and development in this field. The positive market outlook for FRP rebars underscores the potential for continued growth and expansion, as industries seek to enhance the durability and sustainability of their infrastructure projects.

| Report Metric | Details |

| Report Name | Fiber Reinforced Polymer (FRP) Rebars Market |

| Accounted market size in year | US$ 715 million |

| Forecasted market size in 2031 | US$ 989 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hughes Brothers, Schoeck International, Dextra Group, Pultron Composites, Pultrall, Sireg SPa, Kodiac Fiberglass Rebar LLc, Marshall Composite Technologies LLc, ATP SRl, AL-Arfaj Group, Fibrolux Gmbh, International Grating, BP Composites, Armastek, Firep |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |