What is Global Contact Level Sensors Market?

The Global Contact Level Sensors Market is a dynamic and essential segment within the broader sensor industry, focusing on devices that measure the level of liquids or solids within a container or space. These sensors are crucial in various industries, providing accurate and reliable data that helps in maintaining optimal operational efficiency. Contact level sensors work by physically touching the substance they measure, offering precise readings that are vital for processes where exact measurements are necessary. They are used in a wide range of applications, from simple household appliances to complex industrial systems, ensuring that levels are maintained within desired parameters. The market for these sensors is driven by the increasing demand for automation and control in industries such as oil and gas, chemicals, and pharmaceuticals. As industries continue to evolve and require more sophisticated monitoring systems, the demand for contact level sensors is expected to grow. These sensors are integral to maintaining safety, efficiency, and productivity across various sectors, making them a critical component in modern industrial operations. The market's growth is also supported by technological advancements that enhance sensor accuracy, durability, and functionality, catering to the diverse needs of different industries.

Ultrasonic, Microwave/Radar, Optical, Laser, Micro-Electro-Mechanical Systems (MEMS), Other in the Global Contact Level Sensors Market:

Ultrasonic, microwave/radar, optical, laser, micro-electro-mechanical systems (MEMS), and other technologies form the backbone of the Global Contact Level Sensors Market, each offering unique advantages and applications. Ultrasonic sensors use sound waves to detect the level of a substance, making them ideal for applications where non-contact measurement is preferred. They are widely used in industries such as water treatment and food processing, where hygiene and non-intrusive measurement are critical. Microwave or radar sensors, on the other hand, use electromagnetic waves to measure levels, offering high accuracy and reliability even in harsh environments. These sensors are particularly useful in the oil and gas industry, where they can withstand extreme temperatures and pressures. Optical sensors use light to detect levels, providing precise measurements in applications where transparency and cleanliness are essential, such as in pharmaceuticals and chemicals. Laser sensors offer high precision and are used in applications requiring exact measurements, such as in manufacturing processes where even slight deviations can lead to significant issues. MEMS technology, which involves miniaturized mechanical and electro-mechanical elements, is increasingly being used in level sensors due to its compact size and high sensitivity. These sensors are suitable for applications where space is limited, and precision is paramount. Other technologies in the market include capacitive and conductive sensors, which are used in specific applications where their unique properties are advantageous. Capacitive sensors, for example, are used in applications where the dielectric properties of the material being measured are significant, while conductive sensors are used in applications where the material's conductivity is a key factor. Each of these technologies offers distinct benefits, and the choice of sensor depends on the specific requirements of the application, such as the type of material being measured, the environmental conditions, and the desired level of accuracy. As technology continues to advance, the capabilities of these sensors are expected to improve, offering even greater precision and reliability in a wider range of applications.

Consumer Goods, Industrial Manufacturing, Chemicals, Pharmaceuticals, Wastewater, Oil and Gas, Energy and Power, Healthcare, Others in the Global Contact Level Sensors Market:

The Global Contact Level Sensors Market finds extensive usage across various sectors, each with unique requirements and challenges. In the consumer goods industry, these sensors are used in household appliances such as washing machines and refrigerators to ensure optimal performance and efficiency. They help in maintaining the correct levels of water, detergent, and other substances, enhancing the functionality and reliability of these appliances. In industrial manufacturing, contact level sensors are crucial for maintaining the correct levels of raw materials and finished products, ensuring smooth and efficient production processes. They help in reducing waste and improving productivity by providing accurate and reliable data on material levels. In the chemicals industry, these sensors are used to monitor the levels of various chemicals in storage tanks and reactors, ensuring safety and compliance with regulatory standards. They help in preventing overflows and leaks, which can have serious environmental and safety implications. In the pharmaceuticals industry, contact level sensors are used to ensure the correct levels of ingredients in drug manufacturing processes, maintaining the quality and efficacy of the final product. They are also used in packaging processes to ensure the correct fill levels of liquid medications. In the wastewater industry, these sensors are used to monitor the levels of water and sludge in treatment plants, ensuring efficient and effective treatment processes. They help in preventing overflows and ensuring compliance with environmental regulations. In the oil and gas industry, contact level sensors are used to monitor the levels of oil, gas, and other substances in storage tanks and pipelines, ensuring safe and efficient operations. They help in preventing spills and leaks, which can have serious environmental and safety implications. In the energy and power industry, these sensors are used to monitor the levels of various fuels and coolants in power plants, ensuring efficient and reliable operations. They help in maintaining optimal performance and preventing costly downtime. In the healthcare industry, contact level sensors are used in medical devices and equipment to ensure the correct levels of fluids and medications, enhancing patient safety and care. They are also used in laboratory equipment to ensure accurate and reliable test results. Other industries that use contact level sensors include food and beverage, agriculture, and mining, each with unique requirements and challenges. These sensors play a critical role in ensuring safety, efficiency, and productivity across various sectors, making them an essential component in modern industrial operations.

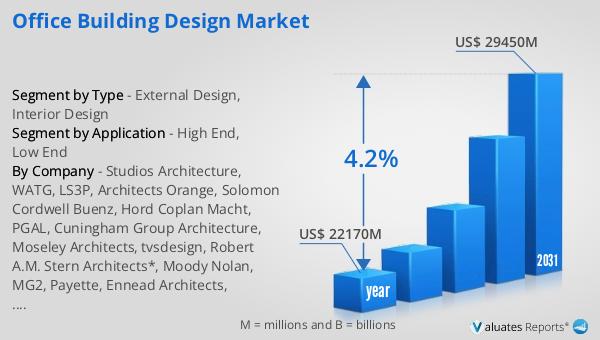

Global Contact Level Sensors Market Outlook:

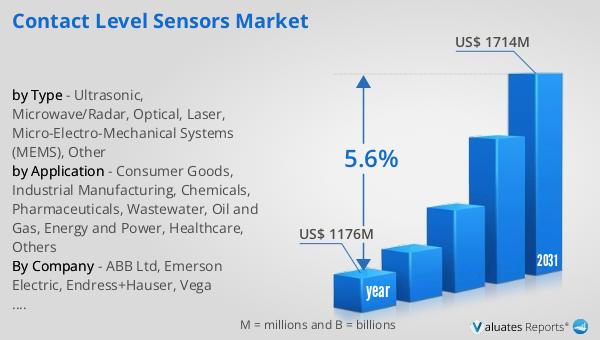

The global market for contact level sensors was valued at $1,176 million in 2024 and is anticipated to expand to a revised size of $1,714 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% over the forecast period. This growth trajectory underscores the increasing demand for these sensors across various industries, driven by the need for precise and reliable level measurement solutions. As industries continue to evolve and adopt more sophisticated technologies, the demand for contact level sensors is expected to rise, supporting their critical role in maintaining operational efficiency and safety. The market's expansion is also fueled by technological advancements that enhance sensor performance, offering improved accuracy, durability, and functionality to meet the diverse needs of different applications. With the growing emphasis on automation and control in industries such as oil and gas, chemicals, and pharmaceuticals, contact level sensors are becoming increasingly important in ensuring optimal performance and compliance with regulatory standards. As a result, the market for these sensors is poised for significant growth, driven by the increasing demand for reliable and accurate level measurement solutions across various sectors.

| Report Metric | Details |

| Report Name | Contact Level Sensors Market |

| Accounted market size in year | US$ 1176 million |

| Forecasted market size in 2031 | US$ 1714 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB Ltd, Emerson Electric, Endress+Hauser, Vega Grieshaber, Siemens, AMETEK, Honeywell International, First Sensor, Fortive Corporation, KROHNE Messtechnik, Pepperl+Fuchs, Nohken, Texas Instruments, TE Connectivity |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |