What is Global TMBPF-DGE Market?

The Global TMBPF-DGE Market refers to the worldwide industry focused on the production, distribution, and application of TMBPF-DGE, a specialized chemical compound. TMBPF-DGE, or Tetramethyl Bisphenol F Diglycidyl Ether, is a type of epoxy resin known for its high-performance characteristics. This compound is primarily used in industries that require materials with excellent thermal stability, chemical resistance, and mechanical strength. The market for TMBPF-DGE is driven by its applications in various sectors, including electronics, coatings, and adhesives. As industries continue to demand materials that can withstand harsh conditions and provide long-lasting performance, the need for TMBPF-DGE is expected to grow. The market is characterized by ongoing research and development efforts aimed at enhancing the properties of TMBPF-DGE and expanding its applications. Companies operating in this market are focused on innovation and sustainability, seeking to develop products that meet the evolving needs of their customers while minimizing environmental impact. The Global TMBPF-DGE Market is a dynamic and competitive landscape, with key players striving to gain a competitive edge through product differentiation and strategic partnerships.

98% Purity, 99% Purity in the Global TMBPF-DGE Market:

In the Global TMBPF-DGE Market, the purity levels of TMBPF-DGE, specifically 98% and 99%, play a crucial role in determining the quality and performance of the end products. The purity of TMBPF-DGE is a significant factor because it directly impacts the material's effectiveness in various applications. A higher purity level, such as 99%, typically indicates fewer impurities, which can enhance the performance characteristics of the compound. For instance, in applications where high thermal stability and chemical resistance are critical, a 99% purity level may be preferred to ensure optimal performance. On the other hand, a 98% purity level, while slightly lower, still offers substantial benefits and may be suitable for applications where the highest purity is not as critical. The choice between 98% and 99% purity levels often depends on the specific requirements of the application and the cost considerations. Higher purity levels generally come with increased production costs, which can affect the pricing of the final product. Therefore, manufacturers and end-users must carefully evaluate the trade-offs between purity, performance, and cost to make informed decisions. In the electronics industry, for example, where precision and reliability are paramount, a 99% purity level may be essential to ensure the longevity and efficiency of electronic components. Similarly, in the coatings industry, where durability and resistance to environmental factors are crucial, a higher purity level can contribute to the overall quality and lifespan of the coatings. However, in some cases, a 98% purity level may be sufficient to meet the desired performance standards while offering cost savings. The demand for different purity levels of TMBPF-DGE is influenced by various factors, including technological advancements, regulatory requirements, and market trends. As industries continue to evolve and innovate, the need for high-purity materials is likely to increase, driving the demand for 99% purity TMBPF-DGE. However, the 98% purity level will also remain relevant, particularly in applications where cost-effectiveness is a priority. Overall, the choice between 98% and 99% purity levels in the Global TMBPF-DGE Market is a critical consideration for manufacturers and end-users alike, as it directly impacts the performance, cost, and competitiveness of their products.

Food Contact Coatings, Epoxy Resin Synthesis, Electronic Encapsulation Materials, Other in the Global TMBPF-DGE Market:

The Global TMBPF-DGE Market finds its applications in various areas, including food contact coatings, epoxy resin synthesis, electronic encapsulation materials, and others. In the realm of food contact coatings, TMBPF-DGE is utilized to create protective layers that prevent food from coming into direct contact with packaging materials. This application is crucial for ensuring food safety and extending the shelf life of packaged goods. The compound's excellent chemical resistance and thermal stability make it an ideal choice for coatings that must withstand exposure to different food substances and temperature variations. In epoxy resin synthesis, TMBPF-DGE serves as a key component in the formulation of high-performance epoxy resins. These resins are widely used in industries such as construction, automotive, and aerospace due to their strong adhesive properties, durability, and resistance to environmental factors. The use of TMBPF-DGE in epoxy resin synthesis enhances the mechanical strength and thermal stability of the resins, making them suitable for demanding applications. In the electronics industry, TMBPF-DGE is employed in the production of electronic encapsulation materials. These materials are used to protect electronic components from moisture, dust, and other environmental factors that could compromise their functionality. The compound's excellent insulating properties and resistance to thermal and chemical degradation make it an ideal choice for encapsulating sensitive electronic components. Additionally, TMBPF-DGE is used in other applications where high-performance materials are required. This includes the production of adhesives, sealants, and coatings for various industrial and consumer applications. The versatility of TMBPF-DGE, combined with its superior performance characteristics, makes it a valuable material in a wide range of industries. As the demand for high-performance materials continues to grow, the Global TMBPF-DGE Market is expected to expand, driven by its applications in these key areas.

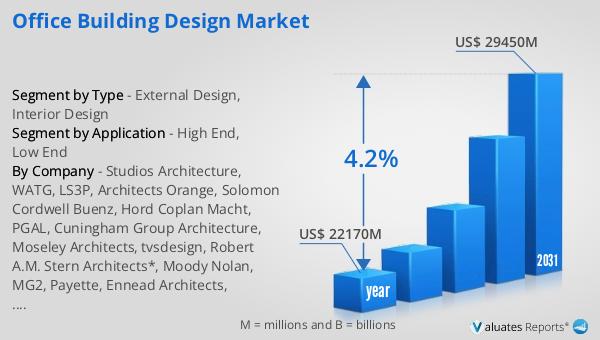

Global TMBPF-DGE Market Outlook:

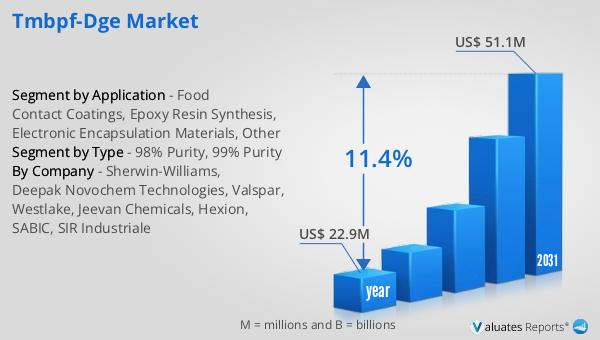

The global market for TMBPF-DGE was valued at $22.9 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $51.1 million by 2031. This growth represents a compound annual growth rate (CAGR) of 11.4% over the forecast period. The market's expansion can be attributed to the increasing demand for high-performance materials across various industries, including electronics, coatings, and adhesives. As industries continue to evolve and innovate, the need for materials that offer superior thermal stability, chemical resistance, and mechanical strength is expected to drive the demand for TMBPF-DGE. The market's growth is also supported by ongoing research and development efforts aimed at enhancing the properties of TMBPF-DGE and expanding its applications. Companies operating in this market are focused on innovation and sustainability, seeking to develop products that meet the evolving needs of their customers while minimizing environmental impact. The competitive landscape of the Global TMBPF-DGE Market is characterized by key players striving to gain a competitive edge through product differentiation and strategic partnerships. As the market continues to grow, companies are likely to invest in new technologies and processes to improve the quality and performance of TMBPF-DGE, further driving its adoption across various industries.

| Report Metric | Details |

| Report Name | TMBPF-DGE Market |

| Accounted market size in year | US$ 22.9 million |

| Forecasted market size in 2031 | US$ 51.1 million |

| CAGR | 11.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sherwin-Williams, Deepak Novochem Technologies, Valspar, Westlake, Jeevan Chemicals, Hexion, SABIC, SIR Industriale |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |