What is Global Noncontact Level Sensors Market?

The Global Noncontact Level Sensors Market is a rapidly evolving sector that focuses on the development and deployment of sensors capable of measuring the level of substances without making physical contact. These sensors are crucial in various industries where contact with the material being measured could lead to contamination, damage, or inaccurate readings. Noncontact level sensors utilize different technologies such as ultrasonic, radar, optical, and laser to detect the level of liquids, solids, or slurries in a container or environment. The demand for these sensors is driven by their ability to provide accurate measurements in challenging conditions, such as extreme temperatures, high pressure, or corrosive environments. They are widely used in industries like oil and gas, chemicals, pharmaceuticals, and wastewater management, where maintaining the integrity of the material being measured is paramount. The market is characterized by continuous innovation, with companies investing in research and development to enhance sensor accuracy, reliability, and ease of integration into existing systems. As industries increasingly prioritize automation and precision, the adoption of noncontact level sensors is expected to grow, making them an integral component of modern industrial processes.

Ultrasonic, Microwave/Radar, Optical, Laser, Micro-Electro-Mechanical Systems (MEMS), Other in the Global Noncontact Level Sensors Market:

Ultrasonic sensors in the Global Noncontact Level Sensors Market operate by emitting sound waves at frequencies beyond human hearing. These waves travel through the air and reflect off the surface of the material being measured. The sensor then calculates the distance based on the time it takes for the waves to return. Ultrasonic sensors are popular due to their versatility and ability to measure levels in both liquids and solids. They are particularly useful in applications where the material's surface is uneven or where there is a risk of contamination from physical contact. However, their performance can be affected by environmental factors such as temperature and humidity, which can alter the speed of sound. Microwave or radar sensors, on the other hand, use electromagnetic waves to detect the level of materials. These sensors are highly effective in harsh environments, as they are not influenced by temperature, pressure, or dust. Radar sensors are ideal for measuring levels in large tanks or silos, where other sensor types might struggle. They offer high accuracy and reliability, making them a preferred choice in industries like oil and gas, where precise measurements are critical. Optical sensors use light to detect the level of a material. They are often used in applications where transparency is required, such as in the food and beverage industry. Optical sensors can provide highly accurate measurements and are not affected by electromagnetic interference, making them suitable for environments with high levels of electrical noise. However, they can be sensitive to dirt or dust on the sensor lens, which can affect their performance. Laser sensors, similar to optical sensors, use light to measure levels but with a laser beam. They offer high precision and are capable of measuring over long distances. Laser sensors are often used in applications where accuracy is paramount, such as in pharmaceuticals or high-value chemical production. They can be more expensive than other sensor types but offer unparalleled accuracy and speed. Micro-Electro-Mechanical Systems (MEMS) sensors are a newer technology in the noncontact level sensor market. These sensors integrate mechanical and electrical components at a microscopic scale, offering compact and highly sensitive solutions. MEMS sensors are used in applications where space is limited, and precision is required. They are increasingly being adopted in consumer electronics and automotive industries due to their small size and low power consumption. Other technologies in the noncontact level sensor market include capacitive and inductive sensors, which use changes in capacitance or inductance to detect material levels. These sensors are often used in specialized applications where other sensor types may not be suitable. Each type of noncontact level sensor offers unique advantages and is chosen based on the specific requirements of the application, such as the type of material being measured, the environmental conditions, and the desired level of accuracy.

Consumer Goods, Industrial Manufacturing, Chemicals, Pharmaceuticals, Wastewater, Oil and Gas, Energy and Power, Healthcare, Others in the Global Noncontact Level Sensors Market:

The Global Noncontact Level Sensors Market finds extensive applications across various industries, each benefiting from the unique capabilities of these sensors. In the consumer goods sector, noncontact level sensors are used to ensure the accurate filling of products such as beverages, detergents, and personal care items. These sensors help maintain product consistency and quality by providing precise measurements without contaminating the product. In industrial manufacturing, noncontact level sensors play a crucial role in monitoring and controlling the levels of raw materials and finished products. They help optimize production processes by ensuring that materials are available when needed, reducing downtime and waste. In the chemicals industry, these sensors are essential for handling hazardous or corrosive substances, where contact with the material could pose safety risks or affect the integrity of the product. Noncontact level sensors provide accurate measurements in challenging environments, ensuring safe and efficient operations. The pharmaceutical industry relies on noncontact level sensors to maintain the purity and quality of products. These sensors are used in the production of drugs and vaccines, where contamination must be avoided at all costs. They provide precise measurements in sterile environments, ensuring compliance with strict regulatory standards. In wastewater management, noncontact level sensors are used to monitor the levels of liquids and solids in treatment plants. They help optimize the treatment process by providing real-time data on the levels of waste materials, ensuring efficient and effective operations. In the oil and gas industry, noncontact level sensors are used to measure the levels of crude oil, refined products, and other materials in tanks and pipelines. They provide accurate measurements in harsh environments, where temperature, pressure, and corrosive substances can affect sensor performance. In the energy and power sector, noncontact level sensors are used to monitor the levels of fuels and other materials in power plants. They help ensure the efficient operation of power generation equipment by providing accurate and reliable measurements. In healthcare, noncontact level sensors are used in medical devices and equipment to monitor fluid levels, ensuring the safe and effective delivery of treatments. These sensors provide accurate measurements without the risk of contamination, making them ideal for use in sterile environments. Other industries, such as food and beverage, mining, and agriculture, also benefit from the use of noncontact level sensors, which provide accurate and reliable measurements in a wide range of applications.

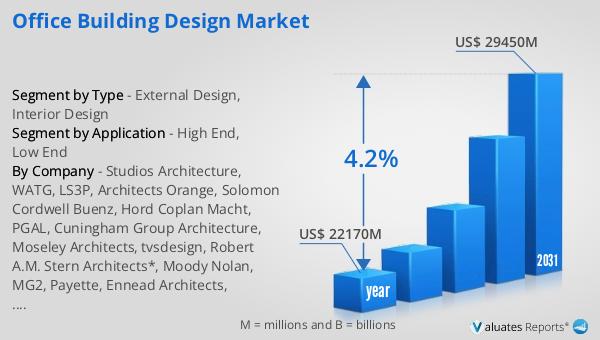

Global Noncontact Level Sensors Market Outlook:

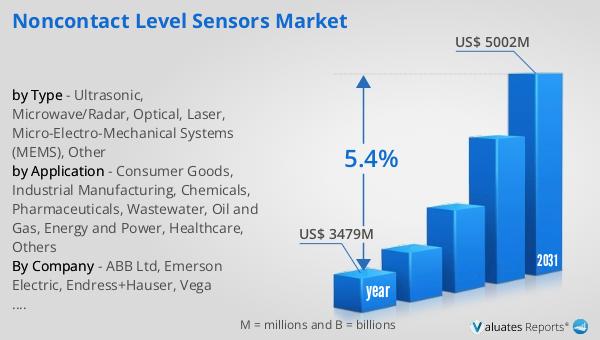

The global market for Noncontact Level Sensors was valued at approximately $3.479 billion in 2024. This market is anticipated to grow significantly, reaching an estimated value of $5.002 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.4% over the forecast period. The increasing demand for precision and automation in various industries is a key driver of this growth. Noncontact level sensors are becoming increasingly important in sectors such as oil and gas, chemicals, pharmaceuticals, and wastewater management, where accurate and reliable measurements are critical. The market is also benefiting from advancements in sensor technology, which are enhancing the accuracy, reliability, and ease of integration of these sensors into existing systems. As industries continue to prioritize efficiency and safety, the adoption of noncontact level sensors is expected to increase, driving further growth in the market. The market's expansion is also supported by the growing trend towards automation and digitalization in industrial processes, which is creating new opportunities for the deployment of noncontact level sensors. Overall, the global noncontact level sensors market is poised for significant growth in the coming years, driven by increasing demand for precision and automation in various industries.

| Report Metric | Details |

| Report Name | Noncontact Level Sensors Market |

| Accounted market size in year | US$ 3479 million |

| Forecasted market size in 2031 | US$ 5002 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB Ltd, Emerson Electric, Endress+Hauser, Vega Grieshaber, Siemens, AMETEK, Honeywell International, First Sensor, Fortive Corporation, KROHNE Messtechnik, Pepperl+Fuchs, Nohken, Texas Instruments, TE Connectivity |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |