What is Global Micro Electric Gripper Market?

The Global Micro Electric Gripper Market is an emerging sector that focuses on the development and application of small, electrically powered gripping devices used in various industries. These grippers are designed to handle delicate and precise tasks, making them ideal for automation processes that require high accuracy and efficiency. Unlike traditional pneumatic or hydraulic grippers, micro electric grippers offer advantages such as reduced energy consumption, quieter operation, and enhanced control over gripping force and speed. They are particularly useful in environments where space is limited and precision is paramount. The market for these devices is expanding rapidly due to the increasing demand for automation in industries like electronics, automotive, and healthcare. As technology advances, micro electric grippers are becoming more sophisticated, with features such as programmable control systems and sensors that enhance their functionality. This growth is driven by the need for more efficient production processes and the rising trend of miniaturization in manufacturing. Companies are investing in research and development to create innovative gripper solutions that can meet the specific needs of different applications, thereby fueling the market's expansion. Overall, the Global Micro Electric Gripper Market is poised for significant growth as industries continue to seek advanced automation solutions.

6 mm, 12 mm, Others in the Global Micro Electric Gripper Market:

In the Global Micro Electric Gripper Market, the size and specifications of grippers play a crucial role in determining their suitability for various applications. Among the most common sizes are 6 mm and 12 mm grippers, along with other variations that cater to specific needs. The 6 mm micro electric grippers are typically used in applications where space is extremely limited, and precision is of utmost importance. These grippers are ideal for handling small components in industries such as electronics and medical devices, where delicate and precise manipulation is required. Their compact size allows them to fit into tight spaces, making them perfect for intricate assembly tasks. On the other hand, 12 mm grippers are slightly larger and are used in applications that require a bit more force and reach. They are commonly found in the automotive and aerospace industries, where they handle components that are larger and heavier than those managed by 6 mm grippers. The increased size of 12 mm grippers allows for a greater range of motion and the ability to exert more force, making them suitable for tasks that involve assembling larger parts or materials. In addition to these standard sizes, the market also offers a variety of other grippers designed to meet specific industry requirements. These may include grippers with specialized jaws or those made from materials that can withstand harsh environments. For instance, in the food and beverage industry, grippers may need to be made from materials that are resistant to corrosion and easy to clean. Similarly, in the pharmaceutical industry, grippers may need to be designed to handle sterile environments and delicate products. The versatility of micro electric grippers is further enhanced by their ability to be customized according to the specific needs of an application. Manufacturers often offer options for customizing the gripping force, speed, and jaw design to ensure that the gripper can perform optimally in its intended environment. This level of customization is particularly important in industries where precision and reliability are critical. As the demand for automation continues to grow, the Global Micro Electric Gripper Market is expected to see an increase in the variety and sophistication of grippers available. Companies are investing in research and development to create innovative solutions that can address the unique challenges faced by different industries. This includes the development of grippers with advanced features such as integrated sensors and programmable control systems that enhance their functionality and adaptability. Overall, the Global Micro Electric Gripper Market is characterized by a wide range of products that cater to the diverse needs of various industries. Whether it's the compact 6 mm grippers for delicate tasks or the more robust 12 mm grippers for heavier applications, the market offers solutions that can meet the demands of modern manufacturing and automation processes. As technology continues to advance, the capabilities of micro electric grippers are expected to expand, further driving their adoption across different sectors.

Aerospace, Automotive, Packaging, Consumer Electronics, Robotics, Others in the Global Micro Electric Gripper Market:

The Global Micro Electric Gripper Market finds its applications across a wide range of industries, each benefiting from the precision and efficiency these devices offer. In the aerospace industry, micro electric grippers are used for assembling intricate components of aircraft and spacecraft. Their ability to handle delicate parts with high precision makes them invaluable in ensuring the reliability and safety of aerospace assemblies. These grippers are often employed in tasks such as wiring, component placement, and fastening, where accuracy is critical. In the automotive sector, micro electric grippers play a crucial role in the automation of assembly lines. They are used for tasks such as picking and placing components, fastening parts, and handling delicate electronic components. The precision and control offered by these grippers help in improving the efficiency and quality of automotive manufacturing processes. In the packaging industry, micro electric grippers are used for handling products of various shapes and sizes. Their ability to adapt to different packaging materials and configurations makes them ideal for tasks such as sorting, packing, and palletizing. These grippers help in streamlining packaging operations, reducing manual labor, and increasing throughput. In the consumer electronics industry, micro electric grippers are used for assembling small and delicate components such as circuit boards, connectors, and displays. Their precision and control are essential in ensuring the quality and reliability of electronic products. These grippers are often used in tasks such as soldering, component placement, and testing, where accuracy is paramount. In the field of robotics, micro electric grippers are used as end-effectors for robotic arms. They enable robots to perform a wide range of tasks, from simple pick-and-place operations to complex assembly processes. The versatility and adaptability of these grippers make them suitable for various robotic applications, including manufacturing, logistics, and healthcare. In addition to these industries, micro electric grippers are also used in other sectors such as healthcare, food and beverage, and pharmaceuticals. In healthcare, they are used for handling delicate medical instruments and devices, while in the food and beverage industry, they are used for packaging and handling food products. In the pharmaceutical industry, micro electric grippers are used for tasks such as filling, capping, and labeling of pharmaceutical products. Overall, the Global Micro Electric Gripper Market is characterized by its wide range of applications across different industries. The precision, efficiency, and adaptability of these grippers make them an essential component of modern automation processes. As industries continue to seek ways to improve their production processes and reduce costs, the demand for micro electric grippers is expected to grow, driving further innovation and development in this market.

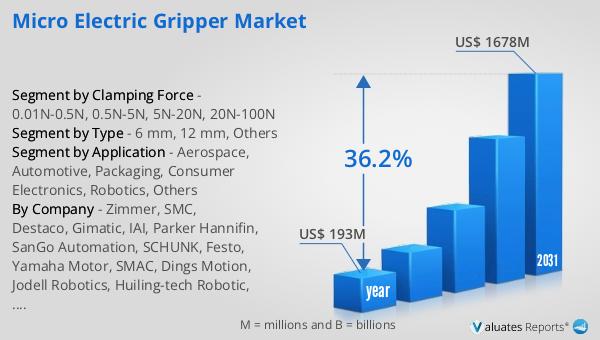

Global Micro Electric Gripper Market Outlook:

The outlook for the Global Micro Electric Gripper Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately $193 million, reflecting the increasing demand for automation solutions across various industries. This demand is driven by the need for more efficient and precise manufacturing processes, as well as the growing trend of miniaturization in product design. As industries continue to adopt automation technologies, the market for micro electric grippers is expected to expand rapidly. By 2031, the market is projected to reach a revised size of $1,678 million, representing a substantial increase from its 2024 valuation. This growth is expected to occur at a compound annual growth rate (CAGR) of 36.2% during the forecast period. The rapid expansion of the market can be attributed to several factors, including advancements in technology, increasing investments in research and development, and the growing adoption of automation solutions in emerging markets. As companies strive to improve their production processes and reduce costs, the demand for micro electric grippers is expected to rise, driving further innovation and development in this sector. Overall, the Global Micro Electric Gripper Market is poised for significant growth, with a promising outlook for the future.

| Report Metric | Details |

| Report Name | Micro Electric Gripper Market |

| Accounted market size in year | US$ 193 million |

| Forecasted market size in 2031 | US$ 1678 million |

| CAGR | 36.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Clamping Force |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Zimmer, SMC, Destaco, Gimatic, IAI, Parker Hannifin, SanGo Automation, SCHUNK, Festo, Yamaha Motor, SMAC, Dings Motion, Jodell Robotics, Huiling-tech Robotic, ElephantRobotics, Hiwin, Daken Tech, DH-Robotics, Foshan Augmented Intelligence, Inspire Robots, Fuyu Automation, WOMMER |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |