What is Global Inductive Proximity Switches Market?

The Global Inductive Proximity Switches Market is a dynamic and rapidly evolving sector within the broader field of industrial automation and control systems. Inductive proximity switches are sensors used to detect the presence of metal objects without physical contact. They operate on the principle of electromagnetic induction, making them highly reliable and durable in various industrial environments. These switches are integral to automation processes, providing precise and efficient control in manufacturing, automotive, packaging, and other industries. The market is driven by the increasing demand for automation and the need for efficient and reliable sensing solutions. With advancements in technology, inductive proximity switches have become more sophisticated, offering enhanced sensitivity, longer sensing ranges, and improved resistance to environmental factors such as dust, moisture, and temperature variations. As industries continue to embrace automation to improve productivity and reduce operational costs, the demand for inductive proximity switches is expected to grow. This market is characterized by a diverse range of products catering to different applications, with manufacturers focusing on innovation and customization to meet specific industry needs. The global market for inductive proximity switches is poised for significant growth, driven by technological advancements and the increasing adoption of automation across various sectors.

DC Type, AC Type in the Global Inductive Proximity Switches Market:

Inductive proximity switches are categorized into two main types based on their power supply requirements: DC type and AC type. The DC type inductive proximity switches are widely used due to their compatibility with low-voltage applications and their ability to provide precise and reliable sensing in various industrial environments. These switches are typically powered by a direct current (DC) source, making them suitable for applications where low power consumption is essential. DC type switches are known for their fast response times and high sensitivity, making them ideal for detecting small metal objects with precision. They are commonly used in applications such as conveyor systems, packaging machinery, and automated assembly lines, where quick and accurate detection is crucial for efficient operation. On the other hand, AC type inductive proximity switches are designed to operate with alternating current (AC) power sources. These switches are often used in applications where higher power levels are required, such as in heavy machinery and industrial equipment. AC type switches are known for their robustness and durability, making them suitable for harsh industrial environments where they may be exposed to dust, moisture, and temperature fluctuations. They are commonly used in industries such as automotive manufacturing, where they play a critical role in ensuring the smooth operation of production lines. Both DC and AC type inductive proximity switches offer unique advantages and are chosen based on the specific requirements of the application. Manufacturers in the global inductive proximity switches market are continuously innovating to enhance the performance and reliability of these switches, catering to the diverse needs of industries worldwide. The choice between DC and AC type switches depends on factors such as power availability, environmental conditions, and the specific sensing requirements of the application. As industries continue to embrace automation and seek efficient sensing solutions, the demand for both DC and AC type inductive proximity switches is expected to grow, driving the overall growth of the global market.

Automobile, Packing, CNC / NC Machines, Conveyor Equipment, Others in the Global Inductive Proximity Switches Market:

The Global Inductive Proximity Switches Market finds extensive usage across various industries, including the automobile, packaging, CNC/NC machines, conveyor equipment, and others. In the automobile industry, inductive proximity switches are used for various applications such as detecting the position of components, monitoring the movement of parts, and ensuring the proper functioning of automated systems. These switches play a crucial role in enhancing the efficiency and safety of automotive manufacturing processes by providing accurate and reliable sensing solutions. In the packaging industry, inductive proximity switches are used to detect the presence and position of packaging materials, ensuring precise and efficient packaging operations. They help in automating the packaging process, reducing manual intervention, and improving overall productivity. In CNC/NC machines, inductive proximity switches are used to detect the position of machine components, ensuring accurate and precise machining operations. These switches help in automating the machining process, reducing errors, and improving the quality of the final product. In conveyor equipment, inductive proximity switches are used to detect the presence and position of materials on the conveyor belt, ensuring smooth and efficient material handling operations. They help in automating the material handling process, reducing manual intervention, and improving overall productivity. In addition to these industries, inductive proximity switches are also used in various other applications such as robotics, material handling, and industrial automation. The versatility and reliability of inductive proximity switches make them an essential component in modern industrial processes, driving their demand across various sectors. As industries continue to embrace automation and seek efficient sensing solutions, the usage of inductive proximity switches is expected to grow, contributing to the overall growth of the global market.

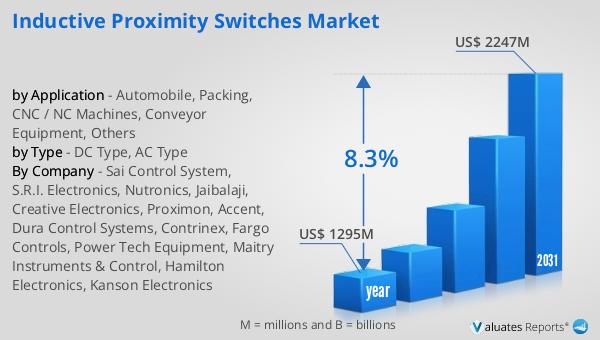

Global Inductive Proximity Switches Market Outlook:

The global market for inductive proximity switches was valued at approximately $1,295 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $2,247 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.3% over the forecast period. The increasing demand for automation and efficient sensing solutions across various industries is a key driver of this growth. Inductive proximity switches are essential components in modern industrial processes, providing reliable and precise sensing capabilities. As industries continue to embrace automation to improve productivity and reduce operational costs, the demand for these switches is expected to rise. The market is characterized by a diverse range of products catering to different applications, with manufacturers focusing on innovation and customization to meet specific industry needs. The choice between DC and AC type switches depends on factors such as power availability, environmental conditions, and the specific sensing requirements of the application. As industries continue to seek efficient sensing solutions, the demand for both DC and AC type inductive proximity switches is expected to grow, driving the overall growth of the global market. The versatility and reliability of inductive proximity switches make them an essential component in modern industrial processes, contributing to the overall growth of the global market.

| Report Metric | Details |

| Report Name | Inductive Proximity Switches Market |

| Accounted market size in year | US$ 1295 million |

| Forecasted market size in 2031 | US$ 2247 million |

| CAGR | 8.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sai Control System, S.R.I. Electronics, Nutronics, Jaibalaji, Creative Electronics, Proximon, Accent, Dura Control Systems, Contrinex, Fargo Controls, Power Tech Equipment, Maitry Instruments & Control, Hamilton Electronics, Kanson Electronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |