What is Global Copper Pillar Bumping Market?

The Global Copper Pillar Bumping Market is a specialized segment within the semiconductor industry that focuses on the use of copper pillars in the manufacturing of integrated circuits. Copper pillar bumping is a process used to create electrical connections between different layers of a semiconductor device. This technique is particularly important in the production of advanced microchips, where the demand for smaller, faster, and more efficient devices is ever-increasing. Copper pillars offer several advantages over traditional solder bumps, including better electrical conductivity, improved thermal performance, and the ability to support finer pitches, which are essential for the miniaturization of electronic components. As technology continues to evolve, the need for high-performance semiconductor devices is driving the growth of the copper pillar bumping market. This market is characterized by continuous innovation and development, as manufacturers strive to meet the demands of various industries, including consumer electronics, telecommunications, automotive, and healthcare. The global copper pillar bumping market is poised for significant growth as it plays a crucial role in enabling the next generation of electronic devices.

in the Global Copper Pillar Bumping Market:

In the Global Copper Pillar Bumping Market, various types of copper pillars are utilized by different customers, each catering to specific needs and applications. One of the primary types is the standard copper pillar, which is widely used due to its excellent electrical and thermal conductivity. These pillars are typically employed in applications where high performance and reliability are crucial, such as in high-frequency devices and power management systems. Another type is the micro copper pillar, which is designed for applications requiring finer pitches and smaller form factors. These are particularly useful in the production of compact and lightweight electronic devices, such as smartphones and wearable technology. Additionally, there are customized copper pillars that are tailored to meet specific customer requirements. These can include variations in height, diameter, and composition to optimize performance for particular applications. For instance, some customers may require copper pillars with enhanced thermal dissipation properties for use in high-power applications, while others may need pillars with specific mechanical properties to withstand harsh environmental conditions. Furthermore, the market also sees the use of copper pillars with integrated under-bump metallization (UBM) layers, which enhance the adhesion and reliability of the connections. This type is particularly favored in applications where long-term durability and stability are paramount, such as in automotive and aerospace industries. The diversity in copper pillar types reflects the wide range of applications and industries that rely on this technology, highlighting its versatility and adaptability. As the demand for more advanced and efficient electronic devices continues to grow, the development and adoption of various copper pillar types are expected to expand, driving further innovation and growth in the market.

in the Global Copper Pillar Bumping Market:

The Global Copper Pillar Bumping Market finds applications across a multitude of industries, each leveraging the unique properties of copper pillars to enhance the performance and efficiency of their electronic devices. In the consumer electronics sector, copper pillar bumping is extensively used in the manufacturing of smartphones, tablets, and laptops. The need for compact, high-performance devices with extended battery life drives the adoption of copper pillars, which offer superior electrical and thermal conductivity compared to traditional solder bumps. This ensures that devices can operate at higher speeds and with greater efficiency, meeting the ever-increasing demands of consumers. In the telecommunications industry, copper pillar bumping plays a critical role in the production of high-frequency devices, such as 5G infrastructure and network equipment. The ability of copper pillars to support finer pitches and higher interconnect densities is essential for the development of advanced communication technologies that require fast and reliable data transmission. Additionally, the automotive industry is increasingly adopting copper pillar bumping in the production of electronic control units (ECUs) and other critical components. As vehicles become more reliant on electronic systems for functions such as navigation, safety, and entertainment, the need for robust and reliable interconnect solutions becomes paramount. Copper pillars provide the necessary performance and durability to withstand the harsh conditions often encountered in automotive environments. Furthermore, the healthcare sector is also benefiting from the advancements in copper pillar bumping technology. Medical devices, such as imaging equipment and portable diagnostic tools, require high-performance electronic components to deliver accurate and reliable results. Copper pillars enable the miniaturization and enhancement of these devices, improving their functionality and usability. Overall, the diverse applications of copper pillar bumping across various industries underscore its importance in the advancement of modern technology, driving innovation and growth in the market.

Global Copper Pillar Bumping Market Outlook:

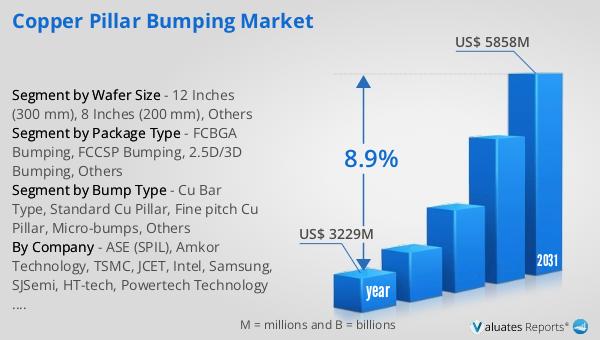

The global market for Copper Pillar Bumping was valued at $3,229 million in 2024, and it is anticipated to expand to a revised size of $5,858 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.9% during the forecast period. This growth trajectory highlights the increasing demand for copper pillar bumping technology across various industries, driven by the need for high-performance and efficient electronic devices. The market's expansion is fueled by continuous advancements in semiconductor manufacturing processes, which are essential for meeting the evolving requirements of modern electronic applications. As industries such as consumer electronics, telecommunications, automotive, and healthcare continue to innovate and develop new technologies, the demand for copper pillar bumping is expected to rise. This growth is further supported by the ongoing trend towards miniaturization and the integration of more functionalities into smaller devices, which necessitates the use of advanced interconnect solutions like copper pillars. The projected growth of the copper pillar bumping market underscores its critical role in enabling the next generation of electronic devices, as manufacturers strive to deliver products that are faster, more efficient, and capable of meeting the demands of an increasingly connected world.

| Report Metric | Details |

| Report Name | Copper Pillar Bumping Market |

| Accounted market size in year | US$ 3229 million |

| Forecasted market size in 2031 | US$ 5858 million |

| CAGR | 8.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Bump Type |

|

| Segment by Package Type |

|

| Segment by Wafer Size |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ASE (SPIL), Amkor Technology, TSMC, JCET, Intel, Samsung, SJSemi, HT-tech, Powertech Technology Inc. (PTI), Tongfu Microelectronics (TFME), Nepes, LB Semicon Inc, SFA Semicon, International Micro Industries, Inc. (IMI), Raytek Semiconductor, Winstek Semiconductor, Hana Micron, ChipMOS TECHNOLOGIES, Chipbond Technology Corporation, Hefei Chipmore Technology, Ningbo ChipEx Semiconductor Co., Ltd, UTAC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |