What is Global Cu Pilliar Bump Market?

The Global Cu Pillar Bump Market is a specialized segment within the semiconductor industry that focuses on the use of copper (Cu) pillar bumps in integrated circuits and electronic devices. These copper pillars are tiny, cylindrical structures that serve as interconnects between different layers of a semiconductor device, facilitating electrical connections. The use of copper, as opposed to traditional solder bumps, offers several advantages, including improved electrical conductivity, better thermal performance, and enhanced mechanical stability. This makes Cu pillar bumps particularly suitable for advanced packaging technologies, such as flip-chip and 3D stacking, which are essential for modern electronic devices that demand higher performance and miniaturization. The market for Cu pillar bumps is driven by the increasing demand for consumer electronics, automotive electronics, and telecommunications equipment, all of which require high-performance and reliable semiconductor components. As technology continues to evolve, the need for efficient and effective interconnect solutions like Cu pillar bumps is expected to grow, making this market a critical component of the broader semiconductor industry. The market is characterized by continuous innovation and development, as manufacturers strive to meet the ever-increasing demands for smaller, faster, and more efficient electronic devices.

Cu Bar Type, Standard Cu Pillar, Fine pitch Cu Pillar, Micro-bumps, Others in the Global Cu Pilliar Bump Market:

In the Global Cu Pillar Bump Market, various types of copper pillar bumps are utilized, each serving distinct purposes and applications. The Cu Bar Type is one such variant, characterized by its elongated, bar-like structure. This type is typically used in applications where a larger contact area is required, providing enhanced mechanical support and electrical connectivity. The Standard Cu Pillar, on the other hand, is the most commonly used type, featuring a cylindrical shape that balances performance and cost-effectiveness. It is widely employed in a range of electronic devices, from smartphones to computers, due to its versatility and reliability. Fine Pitch Cu Pillars are designed for applications requiring high-density interconnections, such as advanced microprocessors and memory chips. These pillars have a smaller diameter and are spaced closer together, allowing for more connections in a limited space, which is crucial for miniaturized devices. Micro-bumps are even smaller than fine pitch pillars and are used in cutting-edge technologies like 3D integrated circuits and system-in-package (SiP) solutions. They enable the stacking of multiple semiconductor dies, significantly enhancing performance and reducing the overall footprint of electronic devices. Other types of Cu pillar bumps may include custom-designed structures tailored for specific applications or emerging technologies. These innovations are driven by the need for higher performance, greater efficiency, and reduced power consumption in modern electronics. As the demand for more compact and powerful devices continues to rise, the development and adoption of various Cu pillar bump types are expected to play a pivotal role in the advancement of semiconductor packaging technologies.

in the Global Cu Pilliar Bump Market:

The Global Cu Pillar Bump Market finds applications across a wide range of industries, each leveraging the unique benefits of copper pillar technology to enhance the performance and reliability of electronic devices. In the consumer electronics sector, Cu pillar bumps are integral to the production of smartphones, tablets, and laptops, where they facilitate high-speed data transfer and efficient power management. The miniaturization trend in consumer electronics necessitates the use of advanced packaging solutions like Cu pillar bumps to accommodate more functionality in smaller form factors. In the automotive industry, the increasing integration of electronic components in vehicles, such as advanced driver-assistance systems (ADAS), infotainment systems, and electric powertrains, drives the demand for reliable and high-performance interconnect solutions. Cu pillar bumps provide the necessary thermal and electrical performance to support these applications, ensuring the safe and efficient operation of automotive electronics. The telecommunications sector also benefits from Cu pillar bump technology, particularly in the development of 5G infrastructure and devices. The high-frequency and high-speed requirements of 5G networks demand robust interconnect solutions that can handle increased data loads and power levels, making Cu pillar bumps an ideal choice. Additionally, the industrial and medical sectors are increasingly adopting Cu pillar bump technology for applications such as industrial automation, medical imaging, and wearable health devices. These applications require high reliability and precision, which Cu pillar bumps can provide through their superior electrical and thermal properties. As technology continues to advance and the demand for more sophisticated electronic devices grows, the applications of Cu pillar bumps are expected to expand further, solidifying their role as a critical component in the semiconductor industry.

Global Cu Pilliar Bump Market Outlook:

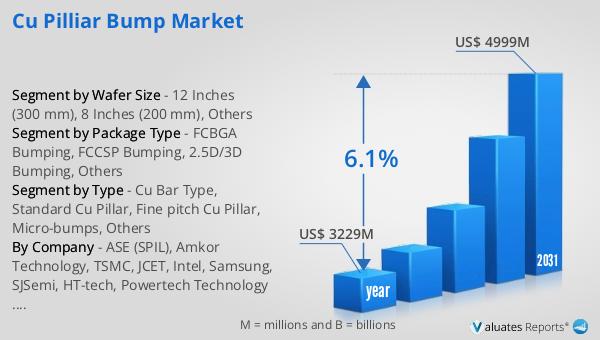

In 2024, the global market for Cu Pillar Bumps was valued at approximately US$ 3,229 million. This market is anticipated to grow significantly, reaching an estimated size of US$ 4,999 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.1% over the forecast period. The market's expansion is driven by the increasing demand for advanced semiconductor packaging solutions across various industries, including consumer electronics, automotive, telecommunications, and industrial applications. The Cu Pillar Bump Market is characterized by a high level of concentration, with the top ten players accounting for over 83 percent of the global market share. This indicates a competitive landscape where leading companies are continuously innovating and investing in research and development to maintain their market positions. The dominance of these key players underscores the importance of technological advancements and strategic partnerships in driving market growth. As the demand for more compact, efficient, and high-performance electronic devices continues to rise, the Cu Pillar Bump Market is poised for sustained growth, offering significant opportunities for both established players and new entrants. The market's outlook reflects the critical role that Cu pillar bumps play in the advancement of semiconductor technology, as they enable the development of next-generation electronic devices that meet the evolving needs of consumers and industries worldwide.

| Report Metric | Details |

| Report Name | Cu Pilliar Bump Market |

| Accounted market size in year | US$ 3229 million |

| Forecasted market size in 2031 | US$ 4999 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Package Type |

|

| Segment by Wafer Size |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ASE (SPIL), Amkor Technology, TSMC, JCET, Intel, Samsung, SJSemi, HT-tech, Powertech Technology Inc. (PTI), Tongfu Microelectronics (TFME), Nepes, LB Semicon Inc, SFA Semicon, International Micro Industries, Inc. (IMI), Raytek Semiconductor, Winstek Semiconductor, Hana Micron, ChipMOS TECHNOLOGIES, Chipbond Technology Corporation, Hefei Chipmore Technology, Ningbo ChipEx Semiconductor Co., Ltd, UTAC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |