What is Global Busbar Trunking Systems Market?

The Global Busbar Trunking Systems Market refers to the worldwide industry focused on the production, distribution, and utilization of busbar trunking systems. These systems are essential components in electrical power distribution, providing a compact and efficient method for transmitting electricity across various sectors. Busbar trunking systems are preferred over traditional cabling due to their flexibility, ease of installation, and ability to handle high power loads. They consist of a series of busbars, which are metallic strips or bars, enclosed in a protective casing. This setup allows for the efficient distribution of electrical power in buildings, factories, and other large structures. The market for these systems is driven by the increasing demand for reliable and efficient power distribution solutions, especially in rapidly urbanizing regions and industrial sectors. As infrastructure development continues to grow globally, the need for advanced electrical distribution systems like busbar trunking is expected to rise, making this market a critical component of the broader electrical equipment industry. The systems are also gaining popularity due to their ability to reduce energy losses and improve safety in power distribution networks.

Copper, Aluminum in the Global Busbar Trunking Systems Market:

In the Global Busbar Trunking Systems Market, copper and aluminum are the primary materials used for manufacturing busbars. Copper is highly favored due to its excellent electrical conductivity, which ensures efficient power transmission with minimal energy loss. This characteristic makes copper busbars ideal for applications where high efficiency and reliability are paramount. Additionally, copper's superior thermal conductivity helps in dissipating heat effectively, reducing the risk of overheating and enhancing the overall safety of the electrical system. Copper busbars are also known for their durability and resistance to corrosion, which contributes to their long lifespan and low maintenance requirements. However, the high cost of copper can be a limiting factor for its widespread adoption, especially in cost-sensitive projects. On the other hand, aluminum busbars offer a cost-effective alternative to copper. Although aluminum has lower electrical conductivity compared to copper, it is significantly lighter and less expensive, making it an attractive option for large-scale projects where budget constraints are a concern. Aluminum's lightweight nature also simplifies the installation process, reducing labor costs and time. Despite its lower conductivity, aluminum busbars can be designed with larger cross-sectional areas to compensate for the difference, ensuring adequate power transmission. However, aluminum is more susceptible to corrosion, particularly in environments with high humidity or exposure to chemicals. To mitigate this, aluminum busbars are often coated or treated to enhance their resistance to environmental factors. The choice between copper and aluminum in busbar trunking systems often depends on the specific requirements of the project, including budget, environmental conditions, and performance expectations. In applications where high performance and reliability are critical, such as in data centers or industrial facilities, copper is typically preferred. Conversely, in projects where cost savings are a priority, aluminum may be the material of choice. The ongoing advancements in material science and engineering continue to improve the performance and cost-effectiveness of both copper and aluminum busbars, ensuring their relevance in the evolving Global Busbar Trunking Systems Market. As the demand for efficient and sustainable power distribution solutions grows, the role of these materials in shaping the future of electrical infrastructure remains significant.

Industrial, Commercial, Large Residential, Transportation in the Global Busbar Trunking Systems Market:

The Global Busbar Trunking Systems Market finds extensive usage across various sectors, including industrial, commercial, large residential, and transportation. In the industrial sector, busbar trunking systems are crucial for distributing power efficiently in manufacturing plants, refineries, and other large facilities. These systems support the high power demands of industrial machinery and equipment, ensuring reliable and uninterrupted power supply. The flexibility and modularity of busbar trunking systems allow for easy reconfiguration and expansion, accommodating the dynamic needs of industrial operations. Additionally, their ability to handle high current loads and reduce energy losses makes them an ideal choice for energy-intensive industries. In the commercial sector, busbar trunking systems are widely used in office buildings, shopping malls, and other commercial establishments. They provide a streamlined and efficient solution for distributing power across multiple floors and areas, supporting the diverse electrical needs of commercial spaces. The aesthetic appeal of busbar trunking systems, with their compact and neat design, is an added advantage in commercial settings where space and appearance are important considerations. Moreover, the ease of installation and maintenance of these systems contributes to reduced operational costs for commercial building owners. Large residential complexes also benefit from the use of busbar trunking systems. As residential buildings become more complex and technologically advanced, the demand for efficient power distribution solutions increases. Busbar trunking systems offer a reliable and safe method for distributing electricity throughout large residential buildings, supporting the growing number of electrical appliances and smart home technologies. Their ability to integrate with renewable energy sources, such as solar panels, further enhances their appeal in residential applications, promoting energy efficiency and sustainability. In the transportation sector, busbar trunking systems play a vital role in powering infrastructure such as airports, railway stations, and ports. These systems ensure the efficient distribution of electricity to support the various operations and services within transportation hubs. The robustness and reliability of busbar trunking systems make them well-suited for the demanding environments of transportation facilities, where continuous power supply is critical. As the transportation sector continues to evolve with the integration of electric vehicles and smart technologies, the demand for advanced power distribution solutions like busbar trunking systems is expected to grow, highlighting their importance in modern infrastructure development.

Global Busbar Trunking Systems Market Outlook:

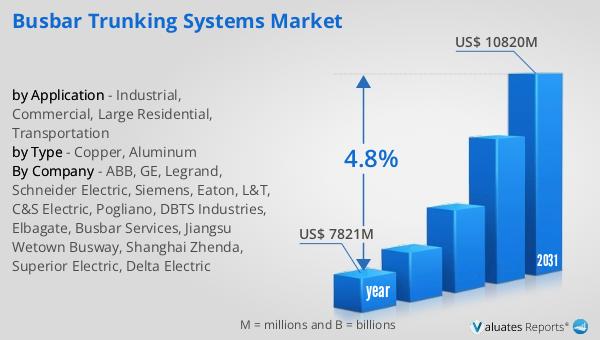

The worldwide market for Busbar Trunking Systems was estimated to be worth $7,821 million in 2024. It is anticipated to expand to a revised valuation of $10,820 million by the year 2031, reflecting a compound annual growth rate (CAGR) of 4.8% over the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable power distribution solutions across various sectors globally. The market's expansion is driven by factors such as rapid urbanization, industrialization, and the growing need for sustainable energy solutions. As more regions invest in infrastructure development and modernization, the adoption of busbar trunking systems is expected to rise, contributing to the market's growth. The systems' advantages, including reduced energy losses, enhanced safety, and ease of installation, make them a preferred choice for power distribution in diverse applications. The projected growth of the market highlights the critical role of busbar trunking systems in supporting the evolving needs of modern infrastructure and energy management. As the market continues to expand, it presents opportunities for innovation and advancement in the design and functionality of busbar trunking systems, ensuring their relevance in the future of electrical power distribution.

| Report Metric | Details |

| Report Name | Busbar Trunking Systems Market |

| Accounted market size in year | US$ 7821 million |

| Forecasted market size in 2031 | US$ 10820 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABB, GE, Legrand, Schneider Electric, Siemens, Eaton, L&T, C&S Electric, Pogliano, DBTS Industries, Elbagate, Busbar Services, Jiangsu Wetown Busway, Shanghai Zhenda, Superior Electric, Delta Electric |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |