What is Global Self-Pierce Riveting System (SPR) Market?

The Global Self-Pierce Riveting System (SPR) Market is a specialized segment within the manufacturing and automotive industries, focusing on a unique fastening technology. Self-pierce riveting is a method used to join two or more layers of material without the need for pre-drilled holes. This technique is particularly valuable in industries where traditional welding or bolting might not be feasible or efficient. The SPR system is widely adopted in the automotive sector, especially with the increasing use of lightweight materials like aluminum and composites, which are difficult to weld. The system involves a rivet that pierces through the top layer of material and flares out to join the layers securely. This method is not only efficient but also enhances the structural integrity of the assembly. As industries continue to seek ways to improve efficiency and reduce weight, the demand for SPR systems is expected to grow. The market is characterized by technological advancements and innovations aimed at improving the speed, precision, and reliability of the riveting process. Companies in this market are continually investing in research and development to enhance their offerings and meet the evolving needs of their customers.

Corded, Cordless in the Global Self-Pierce Riveting System (SPR) Market:

In the Global Self-Pierce Riveting System (SPR) Market, the choice between corded and cordless systems is a significant consideration for manufacturers and users. Corded SPR systems are traditionally favored in environments where consistent power supply and high-volume production are critical. These systems are typically more powerful and can handle larger and more demanding riveting tasks without the need for frequent recharging. They are ideal for assembly lines in large manufacturing plants where the equipment can be permanently stationed. The reliability of a constant power source ensures that production can continue uninterrupted, which is crucial for meeting tight deadlines and maintaining productivity. On the other hand, cordless SPR systems offer flexibility and mobility, which are increasingly important in today's dynamic manufacturing environments. These systems are powered by rechargeable batteries, allowing operators to move freely without being tethered to a power outlet. This mobility is particularly beneficial in applications where the riveting needs to be done in tight or hard-to-reach spaces. Cordless systems are also advantageous in situations where the assembly line layout changes frequently, or where the riveting needs to be done on-site or in remote locations. The advancements in battery technology have significantly improved the performance and longevity of cordless SPR systems, making them a viable option for many applications. However, they may not yet match the power output of corded systems, which can be a limitation for some heavy-duty tasks. The choice between corded and cordless SPR systems ultimately depends on the specific needs of the application, including factors such as the volume of production, the nature of the materials being joined, and the working environment. Manufacturers must weigh the benefits of mobility and flexibility against the need for power and consistency to determine the best solution for their operations. As the market continues to evolve, it is likely that both corded and cordless systems will coexist, each serving distinct niches within the broader SPR market.

Passenger Car, Commercial Vehicle in the Global Self-Pierce Riveting System (SPR) Market:

The Global Self-Pierce Riveting System (SPR) Market finds significant application in the automotive industry, particularly in the production of passenger cars and commercial vehicles. In the passenger car segment, the use of SPR systems is driven by the industry's shift towards lightweight materials to improve fuel efficiency and reduce emissions. Traditional welding methods are often unsuitable for materials like aluminum and composites, which are increasingly used in car bodies and frames. SPR systems provide a reliable and efficient solution for joining these materials, ensuring strong and durable connections without compromising the integrity of the materials. The ability to join dissimilar materials is another advantage of SPR systems, allowing manufacturers to combine different materials to optimize the performance and safety of the vehicle. In commercial vehicles, the demand for SPR systems is similarly influenced by the need for lightweight construction. Commercial vehicles, such as trucks and buses, require robust and durable assemblies to withstand the rigors of heavy-duty use. SPR systems offer a solution that not only meets these durability requirements but also contributes to weight reduction, which is crucial for improving fuel efficiency and payload capacity. The use of SPR systems in commercial vehicles also supports the industry's move towards more sustainable and environmentally friendly manufacturing practices. By enabling the use of lightweight and recyclable materials, SPR systems help manufacturers reduce the environmental impact of their vehicles. Additionally, the efficiency and speed of the SPR process can lead to cost savings in production, making it an attractive option for manufacturers looking to optimize their operations. As the automotive industry continues to evolve, the role of SPR systems in both passenger cars and commercial vehicles is likely to expand, driven by the ongoing pursuit of efficiency, sustainability, and innovation.

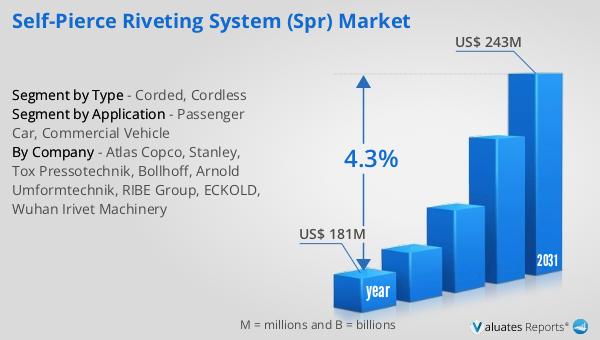

Global Self-Pierce Riveting System (SPR) Market Outlook:

The global market for Self-Pierce Riveting System (SPR) was valued at $181 million in 2024 and is anticipated to grow to a revised size of $243 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% over the forecast period. This growth trajectory underscores the increasing adoption of SPR systems across various industries, driven by the demand for efficient and reliable fastening solutions. The market's expansion is fueled by technological advancements that enhance the performance and capabilities of SPR systems, making them more appealing to manufacturers seeking to improve their production processes. The projected growth also highlights the importance of SPR systems in addressing the challenges associated with joining lightweight and dissimilar materials, which are becoming more prevalent in modern manufacturing. As industries continue to prioritize efficiency, sustainability, and innovation, the SPR market is poised to play a crucial role in supporting these objectives. The steady growth rate indicates a robust demand for SPR systems, reflecting their value in enhancing the structural integrity and performance of assemblies across various applications. This positive market outlook suggests that SPR systems will remain a key component of the manufacturing landscape, offering solutions that align with the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Self-Pierce Riveting System (SPR) Market |

| Accounted market size in year | US$ 181 million |

| Forecasted market size in 2031 | US$ 243 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Atlas Copco, Stanley, Tox Pressotechnik, Bollhoff, Arnold Umformtechnik, RIBE Group, ECKOLD, Wuhan Irivet Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |