What is Global No Clean Cored Solder Wire Market?

The Global No Clean Cored Solder Wire Market is a specialized segment within the electronics manufacturing industry, focusing on solder wires that do not require post-soldering cleaning. These solder wires are infused with a flux core that facilitates the soldering process by cleaning and preparing the metal surfaces to be joined. The "no clean" aspect refers to the flux residues left behind after soldering, which are non-corrosive and non-conductive, eliminating the need for additional cleaning processes. This feature is particularly advantageous in high-volume manufacturing environments where efficiency and cost-effectiveness are paramount. The market for no clean cored solder wire is driven by the increasing demand for electronic devices, advancements in soldering technology, and the push for more environmentally friendly manufacturing processes. As industries continue to innovate and expand, the need for reliable and efficient soldering solutions like no clean cored solder wire is expected to grow, making it a critical component in the production of modern electronic devices. The market is characterized by a variety of products tailored to different applications, including lead-free and leaded options, catering to diverse industry requirements and regulatory standards.

Lead-Free, Leaded in the Global No Clean Cored Solder Wire Market:

In the Global No Clean Cored Solder Wire Market, the distinction between lead-free and leaded solder wires is significant, as it addresses both environmental concerns and technical requirements. Lead-free solder wires are increasingly favored due to stringent environmental regulations and health concerns associated with lead exposure. These solder wires typically contain a combination of tin, silver, and copper, known as SAC alloys, which provide a suitable melting point and mechanical strength for various applications. The transition to lead-free soldering has been driven by legislation such as the Restriction of Hazardous Substances (RoHS) directive in the European Union, which limits the use of certain hazardous materials in electronic equipment. Despite the environmental benefits, lead-free solder wires can present challenges, such as higher melting temperatures and potential reliability issues in certain applications. On the other hand, leaded solder wires, which traditionally consist of a tin-lead alloy, are still used in specific applications where their lower melting point and superior wetting properties are advantageous. These solder wires are often preferred in industries where reliability and performance are critical, such as aerospace and military applications. However, the use of leaded solder is declining due to environmental concerns and regulatory pressures. Manufacturers in the Global No Clean Cored Solder Wire Market are continually innovating to improve the performance of lead-free solder wires, addressing issues such as joint reliability, thermal fatigue, and mechanical strength. This innovation is crucial as industries demand soldering solutions that meet both performance and environmental standards. The market is also witnessing the development of new alloy compositions and flux formulations to enhance the properties of lead-free solder wires, making them more competitive with their leaded counterparts. As the industry evolves, the choice between lead-free and leaded solder wires will depend on a balance of regulatory compliance, performance requirements, and cost considerations. Companies operating in this market must navigate these complexities to provide solutions that meet the diverse needs of their customers while adhering to global environmental standards.

Consumer Electronics, Automotive, Telecommunication, Others in the Global No Clean Cored Solder Wire Market:

The Global No Clean Cored Solder Wire Market plays a vital role in various industries, including consumer electronics, automotive, telecommunication, and others, by providing efficient and reliable soldering solutions. In the consumer electronics sector, no clean cored solder wires are essential for assembling a wide range of devices, from smartphones and tablets to laptops and home appliances. The demand for miniaturized and multifunctional electronic devices drives the need for precise and reliable soldering techniques, making no clean cored solder wires an ideal choice due to their efficiency and reduced cleaning requirements. In the automotive industry, the increasing integration of electronic components in vehicles, such as advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle (EV) components, necessitates the use of high-quality soldering materials. No clean cored solder wires offer the reliability and performance needed to ensure the durability and functionality of these critical electronic systems. The telecommunication industry also relies heavily on no clean cored solder wires for the assembly of communication devices and infrastructure, including smartphones, routers, and base stations. The rapid advancement of 5G technology and the growing demand for high-speed internet connectivity further drive the need for efficient soldering solutions. Additionally, other industries, such as medical devices, aerospace, and industrial electronics, benefit from the use of no clean cored solder wires due to their ability to provide strong and reliable solder joints without the need for additional cleaning processes. This versatility and efficiency make no clean cored solder wires a preferred choice across various applications, supporting the ongoing innovation and development of electronic technologies.

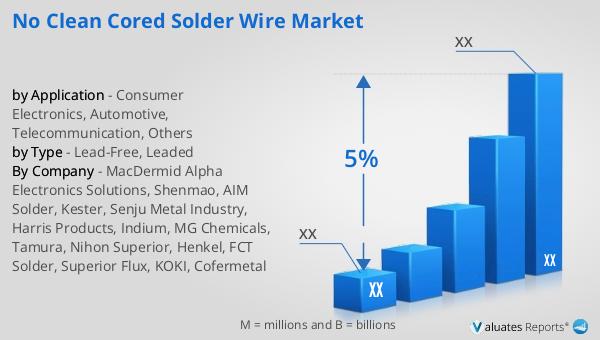

Global No Clean Cored Solder Wire Market Outlook:

The outlook for the Global No Clean Cored Solder Wire Market can be contextualized by examining trends in related industries, such as pharmaceuticals and chemicals. In 2022, the global pharmaceutical market was valued at 1,475 billion USD, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth reflects the increasing demand for healthcare products and innovations in drug development. In comparison, the chemical drug market experienced growth from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. These figures highlight the dynamic nature of global markets and the continuous evolution of industries in response to technological advancements and consumer demands. The Global No Clean Cored Solder Wire Market is similarly influenced by these factors, as the demand for electronic devices and the push for environmentally friendly manufacturing processes drive the need for efficient soldering solutions. As industries continue to innovate and expand, the market for no clean cored solder wire is expected to grow, supported by advancements in soldering technology and the development of new alloy compositions and flux formulations. Companies operating in this market must navigate the complexities of regulatory compliance, performance requirements, and cost considerations to provide solutions that meet the diverse needs of their customers while adhering to global environmental standards.

| Report Metric | Details |

| Report Name | No Clean Cored Solder Wire Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MacDermid Alpha Electronics Solutions, Shenmao, AIM Solder, Kester, Senju Metal Industry, Harris Products, Indium, MG Chemicals, Tamura, Nihon Superior, Henkel, FCT Solder, Superior Flux, KOKI, Cofermetal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |