What is Global Ethylene Propylene Diene Monomer (EPDM) Rubber Sales Market?

The Global Ethylene Propylene Diene Monomer (EPDM) Rubber Sales Market is a significant segment within the broader rubber industry, characterized by its versatile applications and robust demand across various sectors. EPDM rubber is a type of synthetic rubber that is known for its excellent resistance to heat, weather, and ozone, making it an ideal choice for outdoor and automotive applications. This market is driven by the increasing demand for durable and high-performance materials in industries such as automotive, construction, and manufacturing. The global market for EPDM rubber is influenced by factors such as technological advancements, environmental regulations, and the growing need for sustainable materials. As industries continue to seek materials that offer longevity and reliability, EPDM rubber stands out due to its unique properties and adaptability. The market is also shaped by the competitive landscape, with key players investing in research and development to enhance product offerings and meet the evolving needs of consumers. Overall, the Global EPDM Rubber Sales Market is poised for steady growth, driven by its wide-ranging applications and the ongoing demand for high-quality synthetic rubber products.

in the Global Ethylene Propylene Diene Monomer (EPDM) Rubber Sales Market:

The Global Ethylene Propylene Diene Monomer (EPDM) Rubber Sales Market is characterized by a variety of types that cater to the diverse needs of customers across different industries. One of the primary types is solution polymerization EPDM, which is known for its superior quality and performance. This type is highly favored in applications requiring excellent weather resistance and durability, such as automotive weather-stripping and roofing membranes. Another type is suspension polymerization EPDM, which is often used in applications where a balance between cost and performance is essential. This type is commonly utilized in the manufacturing of hoses, seals, and gaskets, where flexibility and resilience are crucial. Additionally, there is the gas-phase polymerization EPDM, which is gaining popularity due to its environmentally friendly production process and enhanced material properties. This type is particularly suitable for applications in the automotive and construction industries, where sustainability and performance are key considerations. Customers in the Global EPDM Rubber Sales Market also benefit from customized formulations that are tailored to specific requirements, such as varying levels of hardness, elasticity, and color. These customized solutions are particularly important for industries that demand precision and consistency, such as the automotive and aerospace sectors. Furthermore, the market is witnessing a growing trend towards bio-based EPDM, which is derived from renewable resources and offers a more sustainable alternative to traditional synthetic rubbers. This type is increasingly being adopted by environmentally conscious companies looking to reduce their carbon footprint and enhance their sustainability credentials. Overall, the Global EPDM Rubber Sales Market offers a wide range of types that cater to the diverse needs of customers, driven by the demand for high-performance, durable, and sustainable materials.

in the Global Ethylene Propylene Diene Monomer (EPDM) Rubber Sales Market:

The Global Ethylene Propylene Diene Monomer (EPDM) Rubber Sales Market finds applications across a wide array of industries, each leveraging the unique properties of EPDM rubber to enhance product performance and durability. In the automotive industry, EPDM rubber is extensively used for weather-stripping, seals, and hoses due to its excellent resistance to heat, ozone, and weathering. This makes it an ideal material for components that are exposed to harsh environmental conditions, ensuring longevity and reliability. The construction industry also benefits significantly from EPDM rubber, particularly in roofing applications. EPDM roofing membranes are renowned for their durability, flexibility, and resistance to UV radiation, making them a popular choice for both residential and commercial buildings. Additionally, EPDM rubber is used in the manufacturing of window and door seals, providing effective insulation and energy efficiency. In the manufacturing sector, EPDM rubber is utilized in the production of various components such as belts, gaskets, and vibration dampeners. Its ability to withstand high temperatures and chemical exposure makes it suitable for demanding industrial applications. Furthermore, the electrical industry employs EPDM rubber for insulation purposes, taking advantage of its excellent electrical resistance and thermal stability. The versatility of EPDM rubber also extends to the consumer goods sector, where it is used in products such as garden hoses, appliance parts, and footwear. Its non-toxic nature and resistance to wear and tear make it a preferred material for consumer applications. Overall, the Global EPDM Rubber Sales Market serves a diverse range of applications, driven by the demand for high-performance materials that offer durability, flexibility, and resistance to environmental factors.

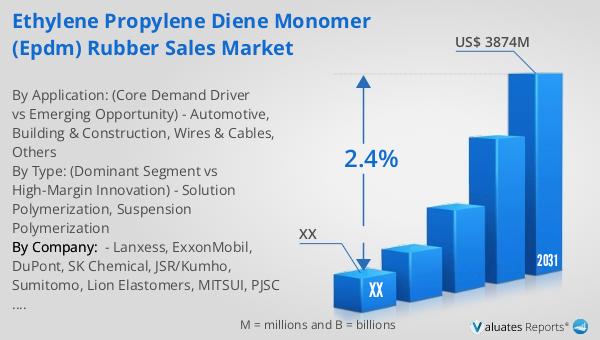

Global Ethylene Propylene Diene Monomer (EPDM) Rubber Sales Market Outlook:

The outlook for the Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market indicates a steady growth trajectory, with the market size projected to increase from US$ 3,289 million in 2024 to an adjusted size of US$ 3,874 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 2.4% during the forecast period from 2025 to 2031. The market is dominated by the top four manufacturers, who collectively hold a significant share of over 65%, highlighting the competitive nature of the industry. Among the various product segments, solution polymerization emerges as the largest, accounting for more than 85% of the market share. This dominance can be attributed to the superior quality and performance characteristics of solution polymerization EPDM, which make it a preferred choice for a wide range of applications. The market's growth is driven by the increasing demand for high-performance materials in industries such as automotive, construction, and manufacturing, where EPDM rubber's unique properties offer significant advantages. As the market continues to evolve, manufacturers are likely to focus on innovation and sustainability to meet the changing needs of consumers and maintain their competitive edge.

| Report Metric | Details |

| Report Name | Ethylene Propylene Diene Monomer (EPDM) Rubber Sales Market |

| Forecasted market size in 2031 | US$ 3874 million |

| CAGR | 2.4% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Lanxess, ExxonMobil, DuPont, SK Chemical, JSR/Kumho, Sumitomo, Lion Elastomers, MITSUI, PJSC Nizhnekamskneftekhim, SABIC, Eni, SSME, Jilin Xingyun Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |