What is Global Remote Machinery Monitoring and Diagnostics Service Market?

The Global Remote Machinery Monitoring and Diagnostics Service Market is a rapidly evolving sector that leverages advanced technologies to monitor and diagnose machinery performance across various industries. This market involves the use of sensors, data analytics, and communication technologies to remotely track the health and efficiency of machinery, ensuring optimal performance and minimizing downtime. By collecting real-time data, these services enable predictive maintenance, allowing companies to address potential issues before they lead to costly failures. This proactive approach not only enhances operational efficiency but also extends the lifespan of machinery. The market is driven by the increasing demand for automation and the need for efficient maintenance strategies in industries such as manufacturing, energy, and transportation. As industries continue to embrace digital transformation, the Global Remote Machinery Monitoring and Diagnostics Service Market is poised for significant growth, offering innovative solutions that enhance productivity and reduce operational costs.

PC-based Control System, PLC-based Control System, Embedded Computer in the Global Remote Machinery Monitoring and Diagnostics Service Market:

PC-based Control Systems, PLC-based Control Systems, and Embedded Computers are integral components of the Global Remote Machinery Monitoring and Diagnostics Service Market, each offering unique advantages and functionalities. PC-based Control Systems utilize personal computers to manage and control machinery operations. These systems are highly flexible, allowing for easy integration with various software applications and providing a user-friendly interface for operators. They are particularly beneficial in environments where complex data processing and visualization are required, as they can handle large volumes of data efficiently. The adaptability of PC-based systems makes them suitable for a wide range of industrial applications, from manufacturing to energy management. On the other hand, PLC-based Control Systems, or Programmable Logic Controllers, are designed for real-time control and automation of machinery processes. PLCs are known for their robustness and reliability, making them ideal for harsh industrial environments. They are capable of executing complex control algorithms and are often used in applications where precision and speed are critical. PLCs are widely used in industries such as automotive, food and beverage, and pharmaceuticals, where they ensure consistent product quality and operational efficiency. Embedded Computers, meanwhile, are specialized computing systems integrated into machinery to perform dedicated functions. These systems are compact, energy-efficient, and designed to operate in specific environments, providing real-time monitoring and control capabilities. Embedded Computers are essential in applications where space and power consumption are constraints, such as in remote monitoring devices and portable diagnostic tools. They offer high reliability and are often used in industries like aerospace, defense, and telecommunications. Each of these control systems plays a crucial role in the Global Remote Machinery Monitoring and Diagnostics Service Market, enabling industries to optimize their operations, enhance productivity, and reduce maintenance costs. By leveraging the strengths of PC-based, PLC-based, and Embedded Computer systems, companies can achieve a comprehensive and efficient approach to machinery monitoring and diagnostics.

Thermal, Water and Wind Power Plants, Chemical Facilities and Refineries, Metallurgy, Construction Industry, Others in the Global Remote Machinery Monitoring and Diagnostics Service Market:

The Global Remote Machinery Monitoring and Diagnostics Service Market finds extensive application across various sectors, including Thermal, Water, and Wind Power Plants, Chemical Facilities and Refineries, Metallurgy, Construction Industry, and others. In Thermal, Water, and Wind Power Plants, remote monitoring services are crucial for ensuring the efficient operation of turbines, generators, and other critical equipment. By continuously tracking performance metrics, these services help in identifying potential issues such as overheating, vibration, or wear and tear, allowing for timely maintenance and reducing the risk of unexpected breakdowns. This not only enhances the reliability of power generation but also contributes to energy efficiency and sustainability. In Chemical Facilities and Refineries, remote machinery monitoring plays a vital role in maintaining the safety and efficiency of complex processes. These facilities often operate under stringent regulatory requirements, and any equipment failure can lead to significant safety hazards and financial losses. Remote monitoring services provide real-time data on equipment health, enabling predictive maintenance and ensuring compliance with safety standards. This proactive approach minimizes downtime and enhances operational efficiency, ultimately leading to cost savings and improved productivity. The Metallurgy sector also benefits from remote machinery monitoring and diagnostics, as it involves heavy machinery and high-temperature processes that require constant supervision. By utilizing remote monitoring services, companies can optimize equipment performance, reduce energy consumption, and extend the lifespan of machinery. This is particularly important in metallurgy, where equipment failure can result in costly production delays and quality issues. In the Construction Industry, remote monitoring services are used to track the performance of construction equipment and machinery, ensuring they operate efficiently and safely. By providing real-time insights into equipment health, these services help in scheduling maintenance activities, reducing downtime, and improving project timelines. This leads to increased productivity and cost-effectiveness in construction projects. Other industries, such as transportation, mining, and manufacturing, also leverage remote machinery monitoring and diagnostics to enhance operational efficiency and reduce maintenance costs. By adopting these services, companies can achieve a competitive edge, improve asset management, and ensure the longevity of their machinery. Overall, the Global Remote Machinery Monitoring and Diagnostics Service Market offers significant benefits across various sectors, driving innovation and efficiency in industrial operations.

Global Remote Machinery Monitoring and Diagnostics Service Market Outlook:

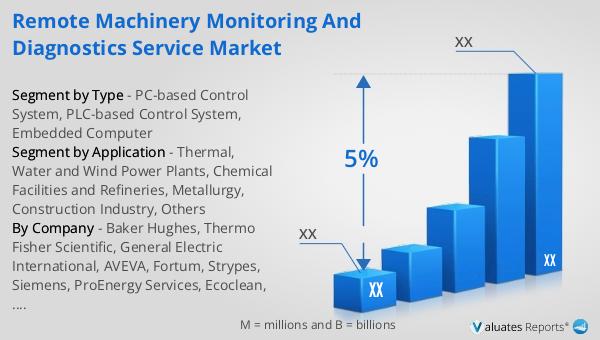

The outlook for the Global Remote Machinery Monitoring and Diagnostics Service Market is promising, with significant growth potential driven by technological advancements and increasing demand for efficient maintenance solutions. In comparison to the pharmaceutical market, which was valued at 1475 billion USD in 2022 and is projected to grow at a CAGR of 5% over the next six years, the chemical drug market has shown a steady increase from 1005 billion USD in 2018 to 1094 billion USD in 2022. This growth reflects the rising demand for innovative solutions and the adoption of advanced technologies across various industries. The Global Remote Machinery Monitoring and Diagnostics Service Market is expected to follow a similar trajectory, as industries continue to embrace digital transformation and seek ways to optimize their operations. By leveraging remote monitoring and diagnostics services, companies can achieve significant cost savings, enhance productivity, and improve asset management. This market is poised to play a crucial role in the future of industrial operations, offering innovative solutions that drive efficiency and sustainability. As industries continue to evolve, the demand for remote machinery monitoring and diagnostics services is expected to grow, providing new opportunities for innovation and growth in the market.

| Report Metric | Details |

| Report Name | Remote Machinery Monitoring and Diagnostics Service Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Baker Hughes, Thermo Fisher Scientific, General Electric International, AVEVA, Fortum, Strypes, Siemens, ProEnergy Services, Ecoclean, ABB, SKF, Eaton, Ferrate Treatment Technologies, Tech Mahindra, Acoem, SumaSoft, Brüel & Kjær Vibro, Nidec Industrial Solutions, Bell and Howell, AVE CARE, PTC, Dimiour, Fives, AMC VIBRO, GE Motors, Define Instruments, AES Reliability, Daikin, Atonix Digital, Sandvik |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |