What is Global Wireless Power Transfer and Charge Systems for Industrial Applications Market?

Global Wireless Power Transfer and Charge Systems for Industrial Applications Market refers to the innovative technology that enables the transfer of electrical energy from a power source to a device without the need for physical connectors or wires. This technology is particularly significant in industrial settings where traditional wired connections can be cumbersome, costly, and prone to wear and tear. Wireless power transfer systems utilize various methods such as electromagnetic induction, magnetic resonance, and magneto-dynamic coupling to efficiently transmit power over short to medium distances. These systems are increasingly being adopted in industries to power automated guided vehicles (AGVs), autonomous mobile robots (AMRs), electric forklifts, and other industrial equipment. The adoption of wireless power transfer systems in industrial applications is driven by the need for increased operational efficiency, reduced maintenance costs, and enhanced safety. By eliminating the need for physical connectors, these systems reduce the risk of electrical faults and improve the reliability of industrial operations. As industries continue to embrace automation and smart technologies, the demand for wireless power transfer systems is expected to grow, offering a promising solution for powering the next generation of industrial equipment.

Electromagnetic Induction, Magnetic Resonance, Magneto-Dynamic Coupling in the Global Wireless Power Transfer and Charge Systems for Industrial Applications Market:

Electromagnetic induction, magnetic resonance, and magneto-dynamic coupling are three key technologies that underpin the Global Wireless Power Transfer and Charge Systems for Industrial Applications Market. Electromagnetic induction is the most widely used method for wireless power transfer. It operates on the principle of Faraday's law of electromagnetic induction, which states that a change in magnetic flux through a coil induces an electromotive force (EMF) in the coil. In practical terms, this means that when an alternating current flows through a primary coil, it creates a changing magnetic field that induces a current in a nearby secondary coil. This method is highly efficient for short-range power transfer and is commonly used in applications such as charging electric vehicles and powering industrial equipment. Magnetic resonance, on the other hand, extends the range of wireless power transfer by using resonant inductive coupling. In this method, both the transmitter and receiver coils are tuned to resonate at the same frequency, allowing for efficient energy transfer over greater distances. This technology is particularly useful in industrial settings where equipment may need to be powered across larger areas without the constraints of physical connectors. Magnetic resonance is also less sensitive to misalignment between the transmitter and receiver, making it a versatile solution for dynamic industrial environments. Magneto-dynamic coupling is a more advanced method that combines elements of both electromagnetic induction and magnetic resonance. It involves the use of dynamic magnetic fields to transfer energy between a transmitter and receiver. This method is still in the experimental stages but holds promise for applications that require high power transfer over long distances. In the context of industrial applications, magneto-dynamic coupling could potentially enable the wireless powering of large machinery and equipment, reducing the need for complex wiring systems. Each of these technologies offers unique advantages and challenges, and their adoption in industrial applications depends on factors such as the required power transfer distance, efficiency, and cost. As the Global Wireless Power Transfer and Charge Systems for Industrial Applications Market continues to evolve, these technologies are expected to play a crucial role in shaping the future of industrial power solutions.

AGVs, AMRs, Electric Forklifts, Cross Belt Sorters, Electrifoed Monorail Systems, Others in the Global Wireless Power Transfer and Charge Systems for Industrial Applications Market:

The usage of Global Wireless Power Transfer and Charge Systems for Industrial Applications Market is particularly prominent in areas such as Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), Electric Forklifts, Cross Belt Sorters, Electrified Monorail Systems, and other industrial equipment. AGVs and AMRs are increasingly being used in manufacturing and warehousing environments to automate material handling processes. Wireless power transfer systems enable these vehicles to operate continuously without the need for manual recharging, thereby increasing their operational efficiency and reducing downtime. Electric forklifts, which are commonly used in warehouses and distribution centers, also benefit from wireless charging systems. By eliminating the need for physical charging connectors, wireless power transfer systems reduce the wear and tear on charging contacts and improve the reliability of forklift operations. Cross belt sorters, which are used in logistics and distribution centers to sort packages and parcels, can also be powered wirelessly. This allows for greater flexibility in the design and layout of sorting systems, as there is no need for complex wiring or physical connectors. Electrified monorail systems, which are used to transport goods and materials within factories and warehouses, can also benefit from wireless power transfer systems. By eliminating the need for physical power rails, these systems reduce maintenance costs and improve the reliability of monorail operations. In addition to these applications, wireless power transfer systems are also being used in other industrial equipment such as conveyor systems, robotic arms, and automated storage and retrieval systems. The adoption of wireless power transfer systems in these areas is driven by the need for increased operational efficiency, reduced maintenance costs, and enhanced safety. As industries continue to embrace automation and smart technologies, the demand for wireless power transfer systems is expected to grow, offering a promising solution for powering the next generation of industrial equipment.

Global Wireless Power Transfer and Charge Systems for Industrial Applications Market Outlook:

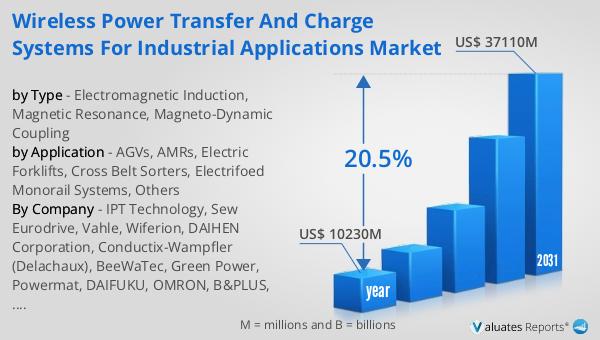

The global market for Wireless Power Transfer and Charge Systems for Industrial Applications was valued at $10,230 million in 2024 and is anticipated to expand significantly, reaching an estimated $37,110 million by 2031. This growth represents a compound annual growth rate (CAGR) of 20.5% over the forecast period. The substantial increase in market size reflects the growing adoption of wireless power transfer systems across various industrial sectors. As industries continue to automate and integrate smart technologies, the demand for efficient and reliable power solutions is on the rise. Wireless power transfer systems offer a compelling alternative to traditional wired connections, providing numerous benefits such as reduced maintenance costs, increased operational efficiency, and enhanced safety. The ability to power industrial equipment without physical connectors not only simplifies the design and layout of industrial systems but also reduces the risk of electrical faults and improves the reliability of operations. As a result, more industries are expected to invest in wireless power transfer systems, driving the market's growth over the coming years. The projected growth of the market underscores the importance of wireless power transfer systems in shaping the future of industrial power solutions, offering a promising avenue for innovation and development in the industrial sector.

| Report Metric | Details |

| Report Name | Wireless Power Transfer and Charge Systems for Industrial Applications Market |

| Accounted market size in year | US$ 10230 million |

| Forecasted market size in 2031 | US$ 37110 million |

| CAGR | 20.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | IPT Technology, Sew Eurodrive, Vahle, Wiferion, DAIHEN Corporation, Conductix-Wampfler (Delachaux), BeeWaTec, Green Power, Powermat, DAIFUKU, OMRON, B&PLUS, WiBotic, etatronix GmbH, In2Power, Delta Electronics, Casun Intellingent Robot, Huachuang Intelligence, Xnergy, Qdzkrx, Nanjing Hery Electric, Boeone Technology, Hertz Innovations Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |