What is Thermal Protective Coating - Global Market?

Thermal protective coatings are specialized materials applied to surfaces to shield them from extreme temperatures, corrosion, and wear. These coatings are crucial in industries where equipment and structures are exposed to high heat, such as aerospace, automotive, and construction. By forming a protective barrier, these coatings help extend the lifespan of components, reduce maintenance costs, and improve safety. The global market for thermal protective coatings is driven by the increasing demand for durable and efficient materials that can withstand harsh environmental conditions. As industries continue to innovate and push the boundaries of technology, the need for advanced thermal protective solutions grows. These coatings are not only essential for protecting assets but also play a significant role in enhancing energy efficiency and reducing environmental impact. With advancements in material science, the development of more effective and sustainable thermal protective coatings is expected to continue, catering to the evolving needs of various sectors. The market's growth is further supported by stringent regulations and standards that require industries to adopt protective measures to ensure safety and compliance. Overall, thermal protective coatings are a vital component in modern industrial applications, offering a blend of protection, performance, and sustainability.

Diffusion Coating, Cover Coating, Thermal Barrier Coating in the Thermal Protective Coating - Global Market:

Diffusion coating, cover coating, and thermal barrier coating are three key types of thermal protective coatings, each serving distinct purposes in the global market. Diffusion coating involves the application of a protective layer through a process that allows the coating material to penetrate the substrate, forming a bond at the molecular level. This type of coating is particularly effective in enhancing the resistance of metals to oxidation and corrosion, making it ideal for components exposed to high temperatures and aggressive environments. Diffusion coatings are commonly used in the aerospace and power generation industries, where the integrity of metal parts is critical for safety and performance. Cover coatings, on the other hand, are designed to provide a physical barrier on the surface of a material. These coatings are typically thicker and are applied to protect against mechanical wear, chemical exposure, and thermal degradation. Cover coatings are versatile and can be used in a wide range of applications, from protecting structural steel in construction to enhancing the durability of automotive parts. Thermal barrier coatings are specialized materials that provide insulation against extreme heat. These coatings are often used in high-temperature environments, such as gas turbines and jet engines, to protect components from thermal fatigue and failure. By reducing the heat transfer to the underlying material, thermal barrier coatings help maintain the structural integrity and performance of critical components. The global market for these coatings is driven by the need for advanced materials that can withstand increasingly demanding conditions. As industries continue to evolve, the demand for diffusion, cover, and thermal barrier coatings is expected to grow, driven by the need for enhanced performance, durability, and efficiency. The development of new coating technologies and materials is also contributing to the market's expansion, offering solutions that are more effective, environmentally friendly, and cost-efficient. Overall, diffusion coating, cover coating, and thermal barrier coating play a vital role in the global thermal protective coating market, providing essential protection and performance benefits across various industries.

Aerospace, Construction, Automobile, Others in the Thermal Protective Coating - Global Market:

Thermal protective coatings are extensively used across several industries, including aerospace, construction, and automotive, due to their ability to protect materials from extreme temperatures and environmental damage. In the aerospace industry, these coatings are crucial for ensuring the safety and performance of aircraft components. They are applied to engine parts, airframes, and other critical components to protect against high temperatures, oxidation, and corrosion. By enhancing the durability and reliability of these parts, thermal protective coatings help reduce maintenance costs and improve the overall efficiency of aircraft. In the construction industry, thermal protective coatings are used to protect buildings and infrastructure from the damaging effects of heat and weather. These coatings are applied to structural steel, concrete, and other materials to prevent thermal degradation and extend the lifespan of buildings. They also play a role in improving energy efficiency by reducing heat transfer and maintaining comfortable indoor temperatures. In the automotive industry, thermal protective coatings are used to protect engine components, exhaust systems, and other parts from high temperatures and wear. By reducing heat transfer and improving thermal management, these coatings help enhance the performance and efficiency of vehicles. Beyond these industries, thermal protective coatings are also used in other sectors, such as power generation, oil and gas, and manufacturing, where equipment and structures are exposed to extreme conditions. The versatility and effectiveness of these coatings make them an essential component in modern industrial applications, providing protection, performance, and sustainability benefits across a wide range of sectors.

Thermal Protective Coating - Global Market Outlook:

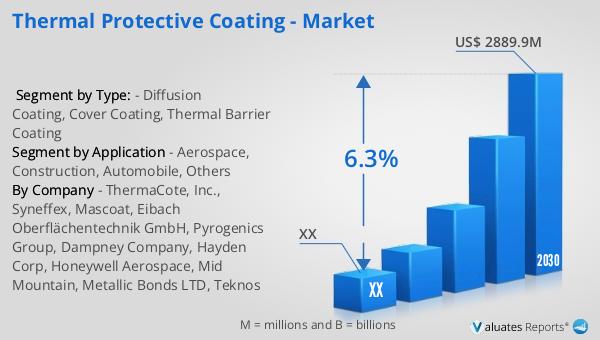

The global market for thermal protective coatings was valued at approximately $1,880 million in 2023. It is projected to grow to a revised size of around $2,889.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for advanced materials that can withstand harsh environmental conditions and enhance the performance and durability of industrial components. In North America, the market for thermal protective coatings was valued at a significant amount in 2023 and is expected to continue its growth trajectory through 2030. The region's market dynamics are influenced by the presence of key industries such as aerospace, automotive, and construction, which require high-performance coatings to protect their assets. The adoption of thermal protective coatings in North America is also supported by stringent regulations and standards that mandate the use of protective measures to ensure safety and compliance. As industries continue to innovate and push the boundaries of technology, the demand for thermal protective coatings is expected to grow, driven by the need for enhanced performance, durability, and efficiency. Overall, the global market for thermal protective coatings is poised for significant growth, offering opportunities for innovation and development in the coming years.

| Report Metric | Details |

| Report Name | Thermal Protective Coating - Market |

| Forecasted market size in 2030 | US$ 2889.9 million |

| CAGR | 6.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ThermaCote, Inc., Syneffex, Mascoat, Eibach Oberflächentechnik GmbH, Pyrogenics Group, Dampney Company, Hayden Corp, Honeywell Aerospace, Mid Mountain, Metallic Bonds LTD, Teknos |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |