What is SMT Automated X-ray Inspection (AXI) - Global Market?

SMT Automated X-ray Inspection (AXI) is a sophisticated technology used in the global market to ensure the quality and reliability of electronic components and printed circuit boards (PCBs). This technology is crucial in the Surface Mount Technology (SMT) industry, where precision and accuracy are paramount. SMT AXI systems use X-ray imaging to inspect the internal structure of electronic components, allowing manufacturers to detect defects that are not visible to the naked eye. These defects can include solder joint issues, component misalignments, and other anomalies that could affect the performance of electronic devices. By using X-ray inspection, manufacturers can ensure that their products meet high-quality standards, reducing the risk of failures and recalls. The global market for SMT AXI is growing as more industries recognize the importance of quality assurance in electronics manufacturing. This growth is driven by the increasing complexity of electronic devices and the need for more reliable inspection methods. As a result, SMT AXI systems are becoming an integral part of the manufacturing process, helping companies maintain their competitive edge in the global market.

2D AXI, 3D AXI in the SMT Automated X-ray Inspection (AXI) - Global Market:

2D and 3D Automated X-ray Inspection (AXI) systems are two primary technologies used in the SMT industry to inspect electronic components and PCBs. 2D AXI systems provide a two-dimensional view of the inspected object, which is useful for identifying surface-level defects and ensuring that components are correctly placed on the PCB. These systems are typically faster and less expensive than their 3D counterparts, making them a popular choice for high-volume production environments where speed and cost are critical factors. However, 2D AXI systems have limitations when it comes to inspecting complex assemblies with multiple layers, as they cannot provide a complete view of the internal structure. On the other hand, 3D AXI systems offer a three-dimensional view, allowing for a more comprehensive inspection of the internal features of electronic components. This capability is particularly important for detecting hidden defects, such as voids in solder joints or misalignments in multi-layer PCBs. 3D AXI systems use advanced imaging techniques, such as computed tomography (CT), to create detailed cross-sectional images of the inspected object. While these systems are generally more expensive and slower than 2D AXI systems, they provide a higher level of accuracy and reliability, making them ideal for applications where quality is paramount. The choice between 2D and 3D AXI systems depends on various factors, including the complexity of the assembly, the required inspection speed, and the budget constraints of the manufacturer. In the global market, both 2D and 3D AXI systems are widely used, with manufacturers often employing a combination of both technologies to achieve optimal inspection results. As electronic devices become more complex and miniaturized, the demand for advanced inspection solutions like 3D AXI is expected to increase, driving further innovation and development in this field. The integration of artificial intelligence and machine learning into AXI systems is also enhancing their capabilities, enabling more accurate defect detection and reducing the need for manual intervention. This technological advancement is helping manufacturers improve their production efficiency and product quality, ultimately benefiting consumers with more reliable electronic devices.

Automotive Electronics, Consumer Electronics, Industrial Electronics, Telecommunications, Aerospace & Military, Others in the SMT Automated X-ray Inspection (AXI) - Global Market:

SMT Automated X-ray Inspection (AXI) systems are used across various industries to ensure the quality and reliability of electronic components and PCBs. In the automotive electronics sector, AXI systems play a crucial role in inspecting components used in safety-critical applications, such as airbags, anti-lock braking systems, and engine control units. These systems help manufacturers detect defects that could lead to failures, ensuring that vehicles meet stringent safety standards. In the consumer electronics industry, AXI systems are used to inspect a wide range of products, from smartphones and tablets to home appliances and wearable devices. As consumer electronics become more complex and feature-rich, the need for reliable inspection methods like AXI is increasing. In the industrial electronics sector, AXI systems are used to inspect components used in automation equipment, power supplies, and other industrial applications. These systems help manufacturers maintain high-quality standards, reducing the risk of equipment failures and downtime. In the telecommunications industry, AXI systems are used to inspect components used in network infrastructure, such as routers, switches, and base stations. These systems help ensure the reliability and performance of communication networks, which are critical for modern society. In the aerospace and military sectors, AXI systems are used to inspect components used in aircraft, satellites, and defense systems. These industries require the highest levels of quality and reliability, making AXI systems an essential part of the manufacturing process. Finally, in other industries, such as medical devices and renewable energy, AXI systems are used to inspect components used in life-saving equipment and sustainable energy solutions. The versatility and effectiveness of AXI systems make them a valuable tool for manufacturers across various sectors, helping them meet the increasing demands for quality and reliability in today's competitive market.

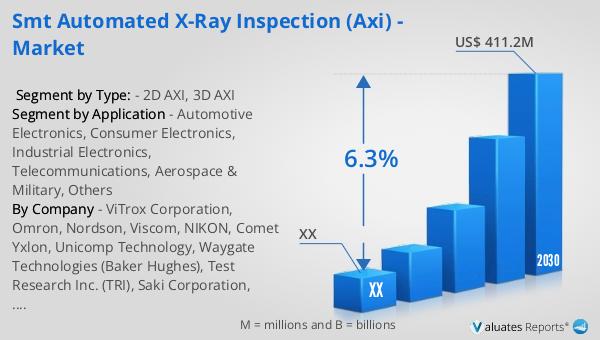

SMT Automated X-ray Inspection (AXI) - Global Market Outlook:

The global market for SMT Automated X-ray Inspection (AXI) was valued at approximately $302 million in 2023. It is projected to grow to a revised size of $411.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.3% during the forecast period from 2024 to 2030. This growth underscores the critical role that AXI technology plays in the Surface Mount Technology (SMT) industry, where it is used to inspect electronic components and printed circuit boards (PCBs). The increasing complexity of electronic devices and the demand for higher quality standards are driving the adoption of AXI systems in various industries. As manufacturers strive to improve product reliability and reduce the risk of defects, the need for advanced inspection solutions like AXI is becoming more apparent. The integration of artificial intelligence and machine learning into AXI systems is further enhancing their capabilities, enabling more accurate defect detection and reducing the need for manual intervention. This technological advancement is helping manufacturers improve their production efficiency and product quality, ultimately benefiting consumers with more reliable electronic devices. As the global market for SMT AXI continues to grow, it is expected to play an increasingly important role in the electronics manufacturing industry, helping companies maintain their competitive edge and meet the evolving demands of consumers.

| Report Metric | Details |

| Report Name | SMT Automated X-ray Inspection (AXI) - Market |

| Forecasted market size in 2030 | US$ 411.2 million |

| CAGR | 6.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ViTrox Corporation, Omron, Nordson, Viscom, NIKON, Comet Yxlon, Unicomp Technology, Waygate Technologies (Baker Hughes), Test Research Inc. (TRI), Saki Corporation, Techvalley, SEC, Seamark ZM, Goepel Electronic, Scienscope |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |