What is Metallocene Low-density Polyethylene for Food Packaging - Global Market?

Metallocene low-density polyethylene (m-LDPE) is a specialized form of polyethylene that is gaining traction in the global food packaging market. This material is produced using metallocene catalysts, which allow for precise control over the polymer structure, resulting in enhanced properties compared to conventional low-density polyethylene (LDPE). m-LDPE is known for its superior clarity, toughness, and sealability, making it an ideal choice for food packaging applications where product visibility and protection are crucial. Its flexibility and strength ensure that packaging can withstand the rigors of transportation and handling while maintaining the integrity of the contents. Additionally, m-LDPE is recyclable, aligning with the growing demand for sustainable packaging solutions. As consumer preferences shift towards more eco-friendly options, the use of m-LDPE in food packaging is expected to rise. This material's ability to provide a reliable barrier against moisture and contaminants further enhances its appeal in preserving food quality and extending shelf life. The global market for m-LDPE in food packaging is poised for growth as manufacturers and consumers alike recognize its benefits in delivering safe, attractive, and sustainable packaging solutions.

Films & Sheets, Injection Moldings, Other in the Metallocene Low-density Polyethylene for Food Packaging - Global Market:

Films and sheets made from metallocene low-density polyethylene (m-LDPE) are pivotal in the food packaging industry due to their exceptional properties. These films and sheets offer excellent clarity, allowing consumers to easily view the product inside, which is a significant advantage for retail displays. The toughness and flexibility of m-LDPE films ensure that they can withstand the stresses of packaging, transportation, and storage without tearing or puncturing. This durability is crucial for maintaining the quality and safety of food products. Moreover, m-LDPE films provide an effective barrier against moisture and contaminants, helping to preserve the freshness and extend the shelf life of packaged foods. The sealability of these films is another key feature, as it ensures that packages remain airtight, preventing spoilage and leakage. In addition to films and sheets, m-LDPE is also used in injection molding applications for food packaging. Injection molding allows for the creation of complex shapes and designs, making it possible to produce a wide range of packaging solutions, from containers and lids to trays and utensils. The precision and consistency offered by m-LDPE in injection molding processes result in high-quality products that meet the stringent requirements of the food industry. Furthermore, m-LDPE's recyclability makes it an attractive option for manufacturers looking to reduce their environmental impact. As sustainability becomes a more pressing concern, the demand for recyclable materials like m-LDPE is expected to increase. Beyond films, sheets, and injection moldings, m-LDPE is also utilized in other food packaging applications, such as coatings and laminations. These applications benefit from the material's excellent adhesion properties, which enhance the performance and durability of the packaging. The versatility of m-LDPE allows it to be used in a variety of packaging formats, catering to the diverse needs of the food industry. As the global market for m-LDPE in food packaging continues to expand, its role in delivering innovative, sustainable, and effective packaging solutions is set to grow.

Bottled Water and Beverages, Food, Health Products, Other in the Metallocene Low-density Polyethylene for Food Packaging - Global Market:

Metallocene low-density polyethylene (m-LDPE) is widely used in the food packaging industry, particularly in areas such as bottled water and beverages, food, health products, and other applications. In the bottled water and beverages sector, m-LDPE is valued for its clarity and strength, which ensure that bottles are both visually appealing and durable. The material's excellent sealability is crucial for maintaining the carbonation and freshness of beverages, preventing leaks and contamination. Additionally, m-LDPE's recyclability aligns with the industry's push towards more sustainable packaging solutions. In the food sector, m-LDPE is used for a variety of packaging formats, including bags, wraps, and containers. Its flexibility and toughness make it ideal for packaging fresh produce, meats, and dairy products, where protection against moisture and contaminants is essential. The material's ability to form airtight seals helps preserve the freshness and quality of food, reducing waste and extending shelf life. For health products, m-LDPE offers a reliable barrier against external elements, ensuring that products remain safe and effective. Its clarity allows consumers to easily identify products, while its strength and durability provide protection during transportation and storage. The recyclability of m-LDPE is also a significant advantage in this sector, as it supports the growing demand for environmentally friendly packaging options. Beyond these specific areas, m-LDPE is used in a range of other food packaging applications, such as coatings and laminations. Its versatility and performance make it a popular choice for manufacturers looking to enhance the functionality and appeal of their packaging. As the global market for m-LDPE in food packaging continues to grow, its usage in these areas is expected to increase, driven by the material's ability to meet the evolving needs of consumers and the industry.

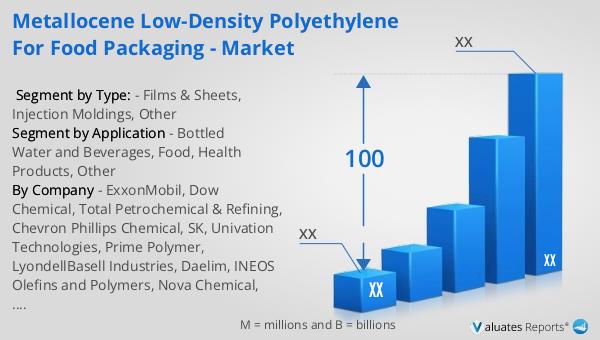

Metallocene Low-density Polyethylene for Food Packaging - Global Market Outlook:

Low-density polyethylene (LDPE) is a versatile, odorless, and transparent thermoplastic polymer that is 100% recyclable, making it a popular choice for various products such as grocery bags, garbage bags, juice containers, and cling wrap. The global market for metallocene low-density polyethylene (m-LDPE) specifically for food packaging was valued at several million US dollars in 2023. It is projected to reach a revised size of several million US dollars by 2030, with a compound annual growth rate (CAGR) over the forecast period from 2024 to 2030. This growth is driven by the increasing demand for sustainable and high-performance packaging materials that can meet the stringent requirements of the food industry. m-LDPE's superior properties, such as clarity, toughness, and sealability, make it an attractive option for manufacturers looking to enhance the quality and appeal of their packaging solutions. As consumer preferences shift towards more eco-friendly options, the market for m-LDPE in food packaging is expected to expand, offering new opportunities for innovation and development in this sector.

| Report Metric | Details |

| Report Name | Metallocene Low-density Polyethylene for Food Packaging - Market |

| CAGR | 100 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ExxonMobil, Dow Chemical, Total Petrochemical & Refining, Chevron Phillips Chemical, SK, Univation Technologies, Prime Polymer, LyondellBasell Industries, Daelim, INEOS Olefins and Polymers, Nova Chemical, Borealis, UBE, Qilu Petrochemical, PTT Global, CNPC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |