What is High Chromium Steel Ball - Global Market?

High chromium steel balls are a crucial component in various industrial applications due to their exceptional hardness, wear resistance, and durability. These balls are primarily made from high chromium steel, which contains a significant percentage of chromium, enhancing their resistance to corrosion and abrasion. The global market for high chromium steel balls is driven by their extensive use in industries such as mining, cement, and thermal power, where they are employed in grinding and milling processes. These balls are essential in reducing the size of materials, improving efficiency, and ensuring the longevity of equipment. The demand for high chromium steel balls is influenced by the growth of these industries, technological advancements, and the need for high-performance materials that can withstand harsh operating conditions. As industries continue to expand and modernize, the global market for high chromium steel balls is expected to grow, driven by the need for reliable and efficient grinding solutions. The market's growth is also supported by the increasing focus on sustainability and energy efficiency, as high chromium steel balls contribute to reducing energy consumption and operational costs in various industrial processes.

10%-12%, 12%-15%, Above 15% in the High Chromium Steel Ball - Global Market:

High chromium steel balls are categorized based on their chromium content, which significantly influences their performance and application. The first category, containing 10%-12% chromium, offers a balance between cost and performance. These balls are suitable for applications where moderate wear resistance is required, such as in certain mining and cement operations. They provide a cost-effective solution for industries that do not require the highest levels of wear resistance but still need reliable performance. The second category, with 12%-15% chromium, offers enhanced wear resistance and durability. These balls are ideal for more demanding applications where higher levels of abrasion and impact resistance are necessary. Industries such as thermal power and metallurgical operations often prefer this category due to its ability to withstand harsh conditions and extend the lifespan of equipment. The third category, containing above 15% chromium, represents the highest level of wear resistance and durability. These balls are used in the most demanding applications, where maximum performance is required. They are particularly suitable for industries that operate under extreme conditions, such as mining operations with high levels of abrasion and impact. The high chromium content ensures that these balls maintain their integrity and performance over extended periods, reducing the need for frequent replacements and minimizing downtime. The choice of chromium content in steel balls depends on the specific requirements of the application, balancing cost, performance, and longevity. As industries continue to evolve and demand more efficient and durable materials, the market for high chromium steel balls with varying chromium content is expected to grow, driven by the need for tailored solutions that meet specific operational needs.

Metallurgical, Cement Industry, Thermal Power, Magnetic Material, Others in the High Chromium Steel Ball - Global Market:

High chromium steel balls are widely used across various industries due to their exceptional properties, making them indispensable in several applications. In the metallurgical industry, these balls are used in grinding and milling processes to reduce the size of ores and other materials. Their high wear resistance and durability ensure efficient grinding, reducing energy consumption and operational costs. In the cement industry, high chromium steel balls are employed in ball mills to grind clinker and other raw materials. Their ability to withstand high temperatures and abrasive conditions makes them ideal for this application, ensuring consistent and efficient production of cement. In thermal power plants, these balls are used in coal pulverizers to grind coal into fine powder for efficient combustion. The high wear resistance of these balls ensures long service life and reduces maintenance costs, contributing to the overall efficiency of power generation. In the production of magnetic materials, high chromium steel balls are used in the milling process to achieve the desired particle size and distribution. Their durability and resistance to wear ensure consistent quality and performance of the final product. Additionally, high chromium steel balls find applications in other industries, such as chemical processing and construction, where their properties contribute to improved efficiency and reduced operational costs. The versatility and performance of high chromium steel balls make them a preferred choice in various industrial applications, driving their demand in the global market.

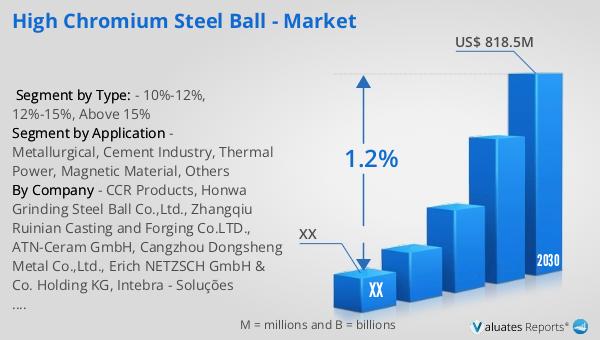

High Chromium Steel Ball - Global Market Outlook:

The global market for high chromium steel balls was valued at approximately $751 million in 2023. It is projected to grow to a revised size of $818.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 1.2% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high-performance grinding solutions across various industries. In North America, the market for high chromium steel balls was valued at a significant amount in 2023, with expectations of reaching a higher value by 2030. The growth in this region is driven by the expansion of industries such as mining, cement, and thermal power, which require efficient and durable grinding solutions. The steady growth rate in the global market highlights the importance of high chromium steel balls in enhancing operational efficiency and reducing costs in industrial processes. As industries continue to evolve and demand more efficient materials, the market for high chromium steel balls is expected to expand, driven by the need for reliable and high-performance grinding solutions.

| Report Metric | Details |

| Report Name | High Chromium Steel Ball - Market |

| Forecasted market size in 2030 | US$ 818.5 million |

| CAGR | 1.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | CCR Products, Honwa Grinding Steel Ball Co.,Ltd., Zhangqiu Ruinian Casting and Forging Co.LTD., ATN-Ceram GmbH, Cangzhou Dongsheng Metal Co.,Ltd., Erich NETZSCH GmbH & Co. Holding KG, Intebra - Soluções complestas em Esferas, KGM Kugelfabrik GmbH & Co. KG, Litzkuhn & Niederwipper GmbH, Mg technical ceramics e.K, Mühlmeier GmbH & Co. KG, Preciball SA, Saluc s.a., Tsubaki Hoover Polska Sp. z o.o. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |