What is Global Wheel Balancing Weight Market?

The Global Wheel Balancing Weight Market is a crucial segment within the automotive industry, focusing on the production and distribution of weights used to balance vehicle wheels. These weights are essential for ensuring smooth and safe driving experiences by preventing vibrations that can occur when wheels are not balanced properly. The market encompasses various types of wheel balancing weights, including clip-on and adhesive types, which cater to different vehicle needs and preferences. As vehicles travel, the distribution of weight around the wheel can become uneven, leading to imbalances that affect the vehicle's handling and tire wear. Wheel balancing weights are applied to the wheel rim to counteract these imbalances, promoting even weight distribution and enhancing vehicle performance. The market is driven by the increasing demand for vehicles globally, advancements in automotive technology, and the need for improved vehicle safety and efficiency. Manufacturers in this market are continually innovating to produce weights that are more durable, environmentally friendly, and compatible with a wide range of vehicles. The Global Wheel Balancing Weight Market is expected to grow steadily as the automotive industry expands and evolves, highlighting the importance of these small yet significant components in vehicle maintenance and safety.

Clip-On Type, Adhesive Type in the Global Wheel Balancing Weight Market:

In the Global Wheel Balancing Weight Market, two primary types of weights are prevalent: Clip-On and Adhesive. Clip-On weights are traditionally used and are favored for their ease of application and removal. They are designed to be clipped onto the wheel rim, making them a quick solution for balancing needs. These weights are typically made from materials like steel, lead, or zinc, each offering different benefits in terms of cost, weight, and environmental impact. Steel is often preferred for its durability and cost-effectiveness, while zinc is chosen for its environmental benefits, as it is less harmful than lead. Lead, although effective, is being phased out in many regions due to environmental concerns. Clip-On weights are particularly popular in regions where labor costs are high, as their quick application reduces the time and cost associated with wheel balancing. On the other hand, Adhesive weights are gaining popularity due to their versatility and aesthetic appeal. These weights are applied using a strong adhesive backing, allowing them to be placed on the inside of the wheel rim, making them less visible and more suitable for alloy wheels where appearance is a concern. Adhesive weights are also made from materials like steel and zinc, with manufacturers focusing on producing weights that offer strong adhesion and resistance to environmental factors such as moisture and temperature changes. The choice between Clip-On and Adhesive weights often depends on the type of vehicle, the wheel design, and the specific requirements of the vehicle owner or service provider. For instance, high-performance vehicles or those with custom wheels may prefer adhesive weights for their discreet appearance and precision. The market for these weights is influenced by factors such as regional regulations, environmental considerations, and advancements in wheel and tire technology. As the automotive industry continues to innovate, the demand for more efficient and environmentally friendly wheel balancing solutions is expected to rise, driving further development and diversification within the Global Wheel Balancing Weight Market. Manufacturers are investing in research and development to create weights that not only meet regulatory standards but also offer enhanced performance and ease of use. This includes exploring new materials and technologies that can provide better balance, reduce environmental impact, and cater to the evolving needs of the automotive industry. The competition between Clip-On and Adhesive weights is likely to continue, with each type offering distinct advantages that appeal to different segments of the market. As consumer preferences and industry standards evolve, the Global Wheel Balancing Weight Market will continue to adapt, providing innovative solutions that enhance vehicle safety, performance, and aesthetics.

Passenger Vehicle, Commercial Vehicle, Motorcycle in the Global Wheel Balancing Weight Market:

The usage of wheel balancing weights is critical across various types of vehicles, including passenger vehicles, commercial vehicles, and motorcycles, each with unique requirements and challenges. In passenger vehicles, wheel balancing weights are essential for ensuring a smooth and comfortable ride. These vehicles, which include cars and SUVs, are primarily used for personal transportation and are expected to provide a high level of comfort and safety. Imbalances in the wheels can lead to vibrations that not only affect the driving experience but also contribute to uneven tire wear and reduced fuel efficiency. By using wheel balancing weights, these issues can be mitigated, leading to improved vehicle performance and longevity. In commercial vehicles, which include trucks, buses, and vans, the need for wheel balancing weights is even more pronounced. These vehicles often carry heavy loads and travel long distances, making them more susceptible to wheel imbalances. Proper wheel balancing is crucial for maintaining stability, safety, and efficiency, as imbalances can lead to increased tire wear, higher fuel consumption, and potential safety hazards. The use of wheel balancing weights in commercial vehicles helps ensure that these vehicles can operate safely and efficiently, reducing maintenance costs and downtime. Motorcycles, while smaller in size, also benefit significantly from wheel balancing weights. Given their two-wheeled design, motorcycles are particularly sensitive to imbalances, which can affect handling and stability. Wheel balancing weights are used to ensure that the wheels rotate evenly, providing a smoother ride and enhancing safety. For motorcycles, the choice of wheel balancing weights is often influenced by factors such as weight, size, and aesthetic considerations, as riders often seek solutions that do not detract from the bike's appearance. Across all these vehicle types, the Global Wheel Balancing Weight Market plays a vital role in enhancing vehicle performance, safety, and efficiency. As the automotive industry continues to grow and evolve, the demand for effective wheel balancing solutions is expected to increase, driving innovation and development within the market. Manufacturers are focusing on creating weights that are not only effective but also environmentally friendly and compatible with a wide range of vehicles. This includes exploring new materials and technologies that can provide better balance, reduce environmental impact, and cater to the evolving needs of the automotive industry. The importance of wheel balancing weights in maintaining vehicle safety and performance cannot be overstated, making them an essential component in the maintenance and operation of passenger vehicles, commercial vehicles, and motorcycles.

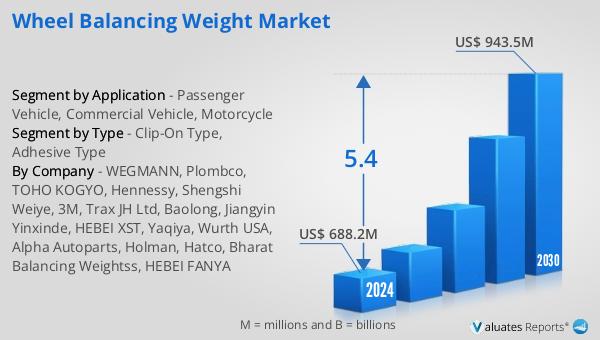

Global Wheel Balancing Weight Market Outlook:

The outlook for the Global Wheel Balancing Weight Market indicates a promising growth trajectory, with the market expected to expand from $688.2 million in 2024 to $943.5 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 5.4% during this period. This growth is driven by several factors, including the increasing demand for vehicles, advancements in automotive technology, and the need for improved vehicle safety and efficiency. Key players in the industry, such as WEGMANN, Plombco, TOHO KOGYO, Hennessy, and Shengshi Weiye, dominate the market, collectively holding about 42% of the market share. These companies are at the forefront of innovation, developing new and improved wheel balancing solutions that cater to the evolving needs of the automotive industry. The Asia Pacific region is the largest consumer of wheel balancing weights, driven by the rapid growth of the automotive industry in countries like China and India. Following closely is Europe, which holds a 22% share of the consumption market. The demand in these regions is fueled by the increasing number of vehicles on the road and the growing awareness of the importance of wheel balancing for vehicle safety and performance. As the market continues to grow, manufacturers are focusing on creating weights that are not only effective but also environmentally friendly and compatible with a wide range of vehicles. This includes exploring new materials and technologies that can provide better balance, reduce environmental impact, and cater to the evolving needs of the automotive industry. The Global Wheel Balancing Weight Market is poised for significant growth, driven by the increasing demand for vehicles and the need for improved vehicle safety and efficiency.

| Report Metric | Details |

| Report Name | Wheel Balancing Weight Market |

| Accounted market size in 2024 | US$ 688.2 million |

| Forecasted market size in 2030 | US$ 943.5 million |

| CAGR | 5.4 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | WEGMANN, Plombco, TOHO KOGYO, Hennessy, Shengshi Weiye, 3M, Trax JH Ltd, Baolong, Jiangyin Yinxinde, HEBEI XST, Yaqiya, Wurth USA, Alpha Autoparts, Holman, Hatco, Bharat Balancing Weightss, HEBEI FANYA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |