What is Global Tape for Photoelectric Display Market?

The Global Tape for Photoelectric Display Market is a specialized segment within the broader electronics and materials industry. This market focuses on the production and distribution of various types of tapes used in photoelectric displays, which are essential components in devices like smartphones, tablets, televisions, and other electronic displays. These tapes play a crucial role in the assembly and functionality of displays, providing necessary support, insulation, and protection to the delicate electronic components. The market is driven by the increasing demand for advanced display technologies, such as OLED and LCD, which require high-performance materials to ensure optimal performance and longevity. As consumer electronics continue to evolve, the need for specialized tapes that can withstand various environmental conditions and enhance display quality is becoming more pronounced. This market is characterized by continuous innovation, with manufacturers striving to develop tapes that offer better adhesion, flexibility, and thermal management properties. The growth of this market is also influenced by the expanding applications of photoelectric displays in various sectors, including automotive and industrial electronics, where durability and reliability are paramount. Overall, the Global Tape for Photoelectric Display Market is poised for significant growth as technology advances and the demand for high-quality displays increases.

PET Substrate Tape, Non-woven Substrate Tape, Foam Tape, Other in the Global Tape for Photoelectric Display Market:

In the Global Tape for Photoelectric Display Market, several types of tapes are utilized, each serving distinct purposes and offering unique properties. PET Substrate Tape is one of the most commonly used tapes in this market. Made from polyethylene terephthalate, this tape is known for its excellent dimensional stability, high tensile strength, and resistance to moisture and chemicals. These properties make PET Substrate Tape ideal for use in environments where durability and reliability are critical. It is often used in the assembly of displays to provide structural support and insulation, ensuring that the delicate electronic components are protected from external factors that could compromise their performance. Non-woven Substrate Tape, on the other hand, is made from fibers bonded together to form a cohesive material. This type of tape is valued for its flexibility, breathability, and ability to conform to irregular surfaces. In the context of photoelectric displays, Non-woven Substrate Tape is used to provide cushioning and protection, particularly in applications where the display may be subject to mechanical stress or impact. Its soft texture and ability to absorb shock make it an excellent choice for protecting sensitive components. Foam Tape is another important type of tape in this market. Composed of a foam core with adhesive on one or both sides, Foam Tape is used for its excellent cushioning properties and ability to fill gaps between components. This tape is particularly useful in applications where vibration damping and sound insulation are required, such as in automotive displays. The foam core provides a barrier that absorbs vibrations and reduces noise, enhancing the overall performance and longevity of the display. Other types of tapes used in the Global Tape for Photoelectric Display Market include adhesive transfer tapes, double-sided tapes, and conductive tapes. Adhesive transfer tapes are used for bonding applications where a thin, uniform layer of adhesive is required. These tapes are often used in the lamination of display components, providing a strong bond without adding bulk. Double-sided tapes are used for mounting and assembly applications, offering strong adhesion on both sides to securely hold components in place. Conductive tapes, which contain conductive particles or layers, are used in applications where electrical conductivity is required, such as in grounding or shielding electronic components. Each type of tape in the Global Tape for Photoelectric Display Market is designed to meet specific requirements, ensuring that displays function optimally and reliably in various applications.

Consumer Electronics, Automotive Electronics, Industrial, Other in the Global Tape for Photoelectric Display Market:

The usage of Global Tape for Photoelectric Display Market extends across several key areas, including consumer electronics, automotive electronics, industrial applications, and others. In the realm of consumer electronics, these tapes are indispensable in the manufacturing and assembly of devices such as smartphones, tablets, laptops, and televisions. The tapes provide essential functions such as bonding, insulation, and protection, ensuring that the displays are securely assembled and protected from environmental factors that could affect their performance. As consumer electronics continue to evolve with thinner and more flexible displays, the demand for advanced tapes that can accommodate these changes is increasing. In automotive electronics, the use of tapes for photoelectric displays is becoming more prevalent as vehicles incorporate more advanced display technologies. These tapes are used in the assembly of infotainment systems, instrument clusters, and heads-up displays, providing the necessary support and protection to ensure that these components function reliably in the demanding automotive environment. The tapes must withstand temperature fluctuations, vibrations, and exposure to various chemicals, making their performance critical to the overall reliability of the vehicle's electronic systems. In industrial applications, tapes for photoelectric displays are used in a variety of settings, including control panels, monitoring systems, and other display-based equipment. These tapes provide the necessary adhesion and protection to ensure that the displays function reliably in harsh industrial environments. The tapes must be able to withstand exposure to dust, moisture, and chemicals, as well as mechanical stress, making their durability and performance essential to the overall reliability of the equipment. Other areas where tapes for photoelectric displays are used include medical devices, aerospace applications, and signage. In medical devices, these tapes are used in the assembly of display-based equipment, providing the necessary support and protection to ensure that the displays function reliably in critical healthcare settings. In aerospace applications, the tapes are used in the assembly of display systems for aircraft, providing the necessary support and protection to ensure that the displays function reliably in the demanding aerospace environment. In signage, the tapes are used in the assembly of display-based signs, providing the necessary support and protection to ensure that the displays function reliably in various environmental conditions. Overall, the usage of Global Tape for Photoelectric Display Market is diverse and continues to expand as new applications for photoelectric displays emerge.

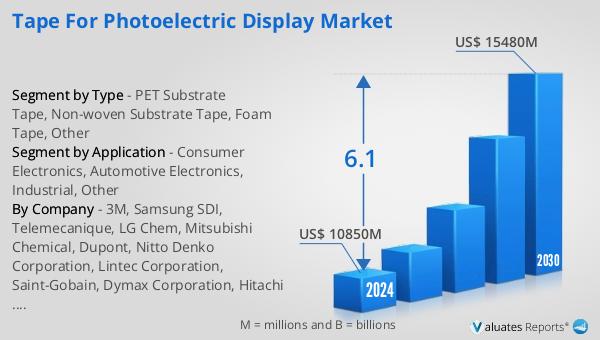

Global Tape for Photoelectric Display Market Outlook:

The outlook for the Global Tape for Photoelectric Display Market indicates a promising growth trajectory over the coming years. The market is anticipated to expand from a valuation of approximately $10,850 million in 2024 to around $15,480 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 6.1% throughout the forecast period. This upward trend is driven by several factors, including the increasing demand for advanced display technologies in consumer electronics, automotive, and industrial sectors. As technology continues to advance, the need for high-performance tapes that can enhance the functionality and durability of photoelectric displays is becoming more pronounced. Manufacturers are focusing on developing innovative tape solutions that offer improved adhesion, flexibility, and thermal management properties to meet the evolving needs of the market. Additionally, the expanding applications of photoelectric displays in various sectors are contributing to the growth of the market. As more industries adopt advanced display technologies, the demand for specialized tapes that can support these applications is expected to rise. Overall, the Global Tape for Photoelectric Display Market is poised for significant growth, driven by technological advancements and the increasing demand for high-quality displays across various sectors.

| Report Metric | Details |

| Report Name | Tape for Photoelectric Display Market |

| Accounted market size in 2024 | US$ 10850 million |

| Forecasted market size in 2030 | US$ 15480 million |

| CAGR | 6.1 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | 3M, Samsung SDI, Telemecanique, LG Chem, Mitsubishi Chemical, Dupont, Nitto Denko Corporation, Lintec Corporation, Saint-Gobain, Dymax Corporation, Hitachi Chemical, Scotch, Oralite, TMS, Bando, Dexerials, OJI, Xinlun New Materials, Highbroad Advanced Material, Keystonetechnology, Jiangsu Sidike New Materials Science & Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |