What is Global Semi-automatic Stacking Machine Market?

The Global Semi-automatic Stacking Machine Market is an essential segment within the broader machinery and equipment industry. These machines are designed to automate the stacking process, which is a crucial step in various manufacturing and packaging operations. Semi-automatic stacking machines offer a blend of manual and automated functions, providing flexibility and efficiency in handling materials. They are particularly valuable in industries where precision and speed are necessary but full automation is not feasible due to cost or complexity. These machines help in reducing labor costs, minimizing errors, and increasing productivity by streamlining the stacking process. The market for these machines is driven by the growing demand for efficient production processes across industries such as food and beverage, pharmaceuticals, and consumer goods. As companies strive to enhance operational efficiency and reduce downtime, the adoption of semi-automatic stacking machines is expected to rise. The market is characterized by technological advancements, with manufacturers focusing on developing machines that offer improved performance, ease of use, and adaptability to different production environments. Overall, the Global Semi-automatic Stacking Machine Market plays a vital role in supporting industrial growth and operational efficiency.

Desktop Type, Floor-standing Type in the Global Semi-automatic Stacking Machine Market:

In the Global Semi-automatic Stacking Machine Market, there are two primary types of machines: Desktop Type and Floor-standing Type. Each type serves distinct purposes and is suited to different operational needs. Desktop Type semi-automatic stacking machines are compact and designed for smaller-scale operations. They are ideal for environments where space is limited, such as small workshops or laboratories. These machines are often used for tasks that require precision and careful handling of materials, making them suitable for industries like electronics, where components need to be stacked with high accuracy. The compact nature of Desktop Type machines allows them to be easily integrated into existing workflows without requiring significant changes to the workspace layout. On the other hand, Floor-standing Type semi-automatic stacking machines are larger and more robust, designed for high-volume operations. These machines are typically used in industrial settings where large quantities of materials need to be stacked quickly and efficiently. Floor-standing machines are equipped with advanced features that enable them to handle heavy loads and operate continuously for extended periods. They are commonly found in industries such as automotive, packaging, and logistics, where speed and reliability are critical. The choice between Desktop Type and Floor-standing Type machines depends on several factors, including the scale of operations, available space, and specific industry requirements. Companies must carefully assess their needs and choose the type of machine that best aligns with their production goals. Both types of machines offer unique advantages and can significantly enhance productivity when used appropriately. As the demand for efficient production processes continues to grow, the Global Semi-automatic Stacking Machine Market is expected to see increased adoption of both Desktop and Floor-standing Type machines. Manufacturers are likely to focus on developing machines that offer greater flexibility, ease of use, and adaptability to meet the evolving needs of various industries.

R&D Test, Small Batch Production in the Global Semi-automatic Stacking Machine Market:

The Global Semi-automatic Stacking Machine Market finds significant usage in areas such as Research and Development (R&D) Testing and Small Batch Production. In R&D Testing, semi-automatic stacking machines play a crucial role in facilitating the development and testing of new products. These machines allow researchers to efficiently stack and organize materials, enabling them to focus on experimentation and innovation. The precision and control offered by semi-automatic machines are particularly valuable in R&D settings, where accuracy is paramount. By automating the stacking process, these machines help reduce the risk of human error, ensuring that test results are reliable and consistent. This is especially important in industries like pharmaceuticals and electronics, where even minor discrepancies can have significant implications. In Small Batch Production, semi-automatic stacking machines offer a cost-effective solution for manufacturers looking to produce limited quantities of products. These machines provide the flexibility needed to handle varying production volumes without the need for extensive manual labor. Small Batch Production is common in industries such as food and beverage, where seasonal products or limited-edition items are produced. Semi-automatic stacking machines enable manufacturers to efficiently manage these smaller production runs, ensuring that products are stacked and packaged with precision and care. The ability to quickly switch between different product types and sizes is another advantage of using semi-automatic machines in Small Batch Production. This adaptability allows manufacturers to respond swiftly to changing market demands and customer preferences. Overall, the use of semi-automatic stacking machines in R&D Testing and Small Batch Production highlights their versatility and importance in modern manufacturing processes. As industries continue to seek ways to improve efficiency and reduce costs, the adoption of these machines is likely to increase, further driving the growth of the Global Semi-automatic Stacking Machine Market.

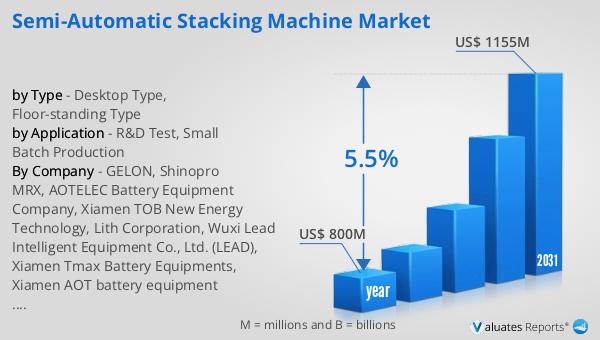

Global Semi-automatic Stacking Machine Market Outlook:

The outlook for the Global Semi-automatic Stacking Machine Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 800 million. By 2031, it is anticipated to expand to a revised size of US$ 1155 million, reflecting a compound annual growth rate (CAGR) of 5.5% over the forecast period. This growth is driven by several factors, including the increasing demand for efficient and cost-effective production solutions across various industries. As companies strive to enhance their operational efficiency and reduce labor costs, the adoption of semi-automatic stacking machines is expected to rise. These machines offer a balance between manual and automated processes, providing the flexibility needed to adapt to different production environments. The market is also benefiting from technological advancements, with manufacturers focusing on developing machines that offer improved performance, ease of use, and adaptability. As a result, the Global Semi-automatic Stacking Machine Market is poised for significant growth, supported by the ongoing demand for efficient production processes and the continuous evolution of machine technology.

| Report Metric | Details |

| Report Name | Semi-automatic Stacking Machine Market |

| Accounted market size in year | US$ 800 million |

| Forecasted market size in 2031 | US$ 1155 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GELON, Shinopro MRX, AOTELEC Battery Equipment Company, Xiamen TOB New Energy Technology, Lith Corporation, Wuxi Lead Intelligent Equipment Co., Ltd. (LEAD), Xiamen Tmax Battery Equipments, Xiamen AOT battery equipment Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |