What is Global Polycarbonate (PC) Plastics Market?

The Global Polycarbonate (PC) Plastics Market is a significant segment within the broader plastics industry, characterized by its versatile applications and robust growth potential. Polycarbonate plastics are a type of thermoplastic polymer known for their high impact resistance, optical clarity, and thermal stability. These properties make them ideal for a wide range of applications across various industries. The market is driven by the increasing demand for lightweight and durable materials in sectors such as automotive, electronics, and construction. Additionally, the growing emphasis on sustainability and recyclability in materials is propelling the demand for polycarbonate plastics, which can be recycled and reused. The market is also influenced by technological advancements that enhance the properties of polycarbonate plastics, making them more efficient and cost-effective. As industries continue to innovate and seek materials that offer both performance and environmental benefits, the Global Polycarbonate (PC) Plastics Market is poised for continued expansion. The market's growth is further supported by the rising urbanization and industrialization in emerging economies, which are increasing the demand for high-performance materials. Overall, the Global Polycarbonate (PC) Plastics Market represents a dynamic and evolving sector with significant opportunities for growth and innovation.

Phosgene, Non-Phosgene in the Global Polycarbonate (PC) Plastics Market:

Phosgene and non-phosgene processes are two primary methods used in the production of polycarbonate plastics, each with distinct characteristics and implications for the Global Polycarbonate (PC) Plastics Market. The phosgene-based process, traditionally the most common method, involves the reaction of bisphenol A (BPA) with phosgene, a toxic gas. This method is known for producing high-quality polycarbonate with excellent optical and mechanical properties. However, the use of phosgene poses significant environmental and safety concerns due to its toxicity and the potential for hazardous emissions. As a result, there has been a growing shift towards non-phosgene processes, which are considered more environmentally friendly and safer. The non-phosgene process, also known as the melt process, involves the transesterification of BPA with diphenyl carbonate (DPC). This method eliminates the need for phosgene, reducing the environmental impact and improving safety. The non-phosgene process is gaining traction in the market due to its advantages in terms of sustainability and regulatory compliance. It also offers cost benefits by simplifying the production process and reducing the need for complex safety measures associated with phosgene handling. The shift towards non-phosgene processes is further driven by increasing regulatory pressures and consumer demand for greener products. As companies strive to meet these demands, the adoption of non-phosgene processes is expected to increase, influencing the dynamics of the Global Polycarbonate (PC) Plastics Market. The transition to non-phosgene processes also aligns with the broader industry trend towards sustainable manufacturing practices, which prioritize reducing environmental impact and enhancing resource efficiency. This shift is supported by advancements in technology that have improved the efficiency and quality of non-phosgene processes, making them a viable alternative to traditional methods. The growing preference for non-phosgene processes is also reflected in the strategic initiatives of major market players, who are investing in research and development to enhance their non-phosgene production capabilities. These efforts are aimed at improving the performance and cost-effectiveness of non-phosgene polycarbonate plastics, thereby increasing their competitiveness in the market. The transition to non-phosgene processes is not without challenges, as it requires significant investment in new technologies and infrastructure. However, the long-term benefits in terms of sustainability, safety, and cost savings make it an attractive option for companies looking to enhance their market position and meet evolving consumer and regulatory demands. Overall, the shift from phosgene to non-phosgene processes represents a significant trend in the Global Polycarbonate (PC) Plastics Market, with implications for production methods, market dynamics, and competitive strategies. As the industry continues to evolve, the adoption of non-phosgene processes is expected to play a crucial role in shaping the future of the market, driving innovation and growth in the polycarbonate plastics sector.

Consumer Electronics, Automotive, Construction, Packaging, Others in the Global Polycarbonate (PC) Plastics Market:

The Global Polycarbonate (PC) Plastics Market finds extensive usage across various sectors, including consumer electronics, automotive, construction, packaging, and others, each leveraging the unique properties of polycarbonate plastics to enhance product performance and functionality. In the consumer electronics sector, polycarbonate plastics are widely used due to their excellent impact resistance, optical clarity, and thermal stability. These properties make them ideal for manufacturing components such as smartphone cases, laptop casings, and optical discs, where durability and aesthetic appeal are crucial. The lightweight nature of polycarbonate plastics also contributes to the development of portable and user-friendly electronic devices. In the automotive industry, polycarbonate plastics are increasingly used to replace traditional materials like glass and metal, driven by the need for lightweight and fuel-efficient vehicles. Polycarbonate is used in applications such as headlamp lenses, interior components, and glazing, offering benefits such as reduced weight, improved safety, and enhanced design flexibility. The construction sector also benefits from the use of polycarbonate plastics, particularly in applications requiring transparency and impact resistance, such as roofing, glazing, and skylights. Polycarbonate's ability to withstand harsh weather conditions and its excellent thermal insulation properties make it a preferred choice for modern architectural designs. In the packaging industry, polycarbonate plastics are used for their durability and clarity, making them suitable for high-end packaging solutions that require both protection and visual appeal. Additionally, polycarbonate's recyclability aligns with the growing demand for sustainable packaging materials. Beyond these sectors, polycarbonate plastics are used in various other applications, including medical devices, optical lenses, and safety equipment, where their unique combination of properties offers significant advantages. The versatility and performance of polycarbonate plastics continue to drive their adoption across diverse industries, contributing to the growth and expansion of the Global Polycarbonate (PC) Plastics Market. As industries continue to innovate and seek materials that offer both performance and environmental benefits, the demand for polycarbonate plastics is expected to increase, further solidifying their position as a critical material in modern manufacturing and design.

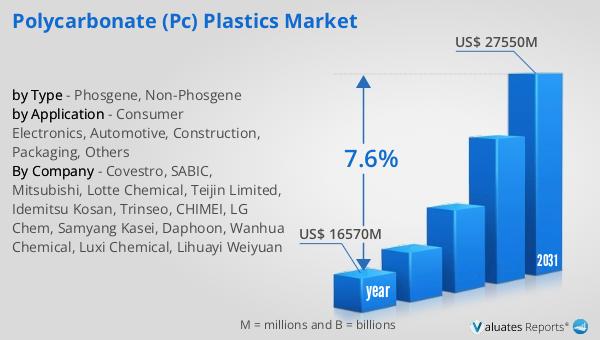

Global Polycarbonate (PC) Plastics Market Outlook:

The global market for Polycarbonate (PC) Plastics was valued at $16,570 million in 2024, with projections indicating a substantial growth trajectory. By 2031, the market is expected to reach a revised size of $27,550 million, reflecting a compound annual growth rate (CAGR) of 7.6% during the forecast period. This growth is driven by the increasing demand for polycarbonate plastics across various industries, including automotive, electronics, and construction, where their unique properties offer significant advantages. The market's expansion is also supported by technological advancements that enhance the performance and cost-effectiveness of polycarbonate plastics, making them more attractive to manufacturers and consumers alike. Additionally, the growing emphasis on sustainability and recyclability in materials is propelling the demand for polycarbonate plastics, which can be recycled and reused. As industries continue to innovate and seek materials that offer both performance and environmental benefits, the Global Polycarbonate (PC) Plastics Market is poised for continued growth and development. The market's growth is further supported by the rising urbanization and industrialization in emerging economies, which are increasing the demand for high-performance materials. Overall, the Global Polycarbonate (PC) Plastics Market represents a dynamic and evolving sector with significant opportunities for growth and innovation.

| Report Metric | Details |

| Report Name | Polycarbonate (PC) Plastics Market |

| Accounted market size in year | US$ 16570 million |

| Forecasted market size in 2031 | US$ 27550 million |

| CAGR | 7.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Covestro, SABIC, Mitsubishi, Lotte Chemical, Teijin Limited, Idemitsu Kosan, Trinseo, CHIMEI, LG Chem, Samyang Kasei, Daphoon, Wanhua Chemical, Luxi Chemical, Lihuayi Weiyuan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |