What is Global Pneumatic Rotary Table Market?

The Global Pneumatic Rotary Table Market refers to the industry focused on the production and distribution of pneumatic rotary tables, which are devices used to rotate objects around a fixed axis. These tables are powered by compressed air and are widely used in various industrial applications due to their precision, reliability, and ease of use. The market encompasses a range of products designed to meet different needs, from small-scale operations to large industrial applications. Pneumatic rotary tables are essential in automation processes, where they help in positioning, indexing, and rotating components with high accuracy. The market is driven by the increasing demand for automation in manufacturing and other sectors, as well as the need for efficient and cost-effective solutions. As industries continue to evolve and seek more advanced technologies, the Global Pneumatic Rotary Table Market is expected to grow, offering new opportunities for innovation and development. The market's growth is also supported by advancements in technology, which have led to the development of more sophisticated and versatile pneumatic rotary tables. These advancements have made it possible for manufacturers to offer products that are not only more efficient but also more adaptable to different industrial needs.

Horizontal, Vertical, Tilting in the Global Pneumatic Rotary Table Market:

In the Global Pneumatic Rotary Table Market, products are often categorized based on their orientation and functionality, namely horizontal, vertical, and tilting rotary tables. Horizontal pneumatic rotary tables are designed to rotate objects in a plane parallel to the ground. They are commonly used in applications where stability and precision are crucial, such as in machining and assembly processes. These tables provide a stable platform for workpieces, allowing for accurate positioning and rotation. Horizontal tables are particularly useful in operations that require repetitive and precise movements, making them a staple in manufacturing environments. Vertical pneumatic rotary tables, on the other hand, rotate objects in a plane perpendicular to the ground. They are ideal for applications where space is limited or where the workpiece needs to be rotated vertically. Vertical tables are often used in conjunction with other machinery, such as milling machines or drilling equipment, to enhance their functionality and improve efficiency. They are also favored in applications that require vertical alignment or where the workpiece needs to be accessed from different angles. Tilting pneumatic rotary tables offer the best of both worlds, providing the ability to rotate objects in both horizontal and vertical planes. These versatile tables are designed to tilt at various angles, allowing for greater flexibility in positioning and orientation. Tilting tables are particularly useful in complex machining operations where multiple angles and orientations are required. They enable operators to perform intricate tasks with ease, reducing the need for manual adjustments and improving overall productivity. The choice between horizontal, vertical, and tilting pneumatic rotary tables depends on the specific requirements of the application, including the size and weight of the workpiece, the desired orientation, and the available space. Each type of table offers unique advantages and can be customized to meet the needs of different industries. As the Global Pneumatic Rotary Table Market continues to grow, manufacturers are focusing on developing more advanced and versatile products to cater to the diverse needs of their customers. This includes the integration of smart technologies, such as sensors and automation systems, to enhance the performance and functionality of pneumatic rotary tables. These innovations are expected to drive further growth in the market, providing new opportunities for businesses to improve their operations and achieve greater efficiency.

Industrial, Sicentific Research in the Global Pneumatic Rotary Table Market:

The Global Pneumatic Rotary Table Market finds extensive usage in various areas, including industrial applications and scientific research. In industrial settings, pneumatic rotary tables are indispensable tools for automation and precision tasks. They are widely used in manufacturing processes, where they facilitate the accurate positioning and rotation of workpieces. This is particularly important in industries such as automotive, aerospace, and electronics, where precision and efficiency are paramount. Pneumatic rotary tables help streamline production processes, reduce manual labor, and improve overall productivity. They are also used in assembly lines, where they enable the precise alignment and positioning of components, ensuring that each part is correctly placed and secured. In scientific research, pneumatic rotary tables play a crucial role in experiments and testing procedures that require precise movement and positioning. They are used in laboratories and research facilities to rotate samples, instruments, or equipment with high accuracy. This is essential in fields such as materials science, physics, and chemistry, where precise control over the orientation and position of samples is necessary for accurate measurements and observations. Pneumatic rotary tables provide researchers with the ability to conduct experiments with greater precision and reliability, leading to more accurate and reproducible results. Additionally, these tables are used in testing and calibration processes, where they help ensure that instruments and equipment are properly aligned and functioning correctly. The versatility and reliability of pneumatic rotary tables make them valuable tools in both industrial and scientific settings, where they contribute to improved efficiency, accuracy, and productivity. As the demand for automation and precision continues to grow, the Global Pneumatic Rotary Table Market is expected to expand, offering new opportunities for innovation and development in various fields.

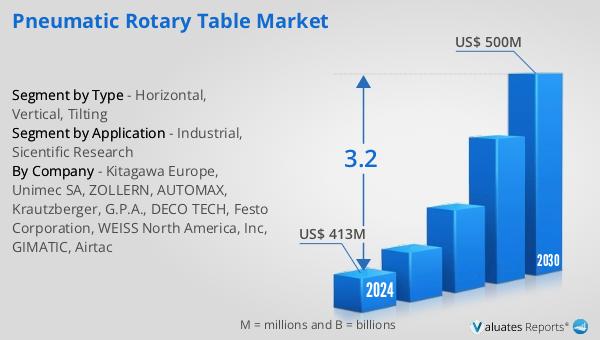

Global Pneumatic Rotary Table Market Outlook:

The outlook for the Global Pneumatic Rotary Table Market indicates a promising growth trajectory over the coming years. The market is anticipated to expand from a valuation of $413 million in 2024 to approximately $500 million by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of 3.2% during the forecast period. This steady increase in market size reflects the rising demand for pneumatic rotary tables across various industries, driven by the need for automation and precision in manufacturing and other sectors. The market's growth is also supported by technological advancements that have led to the development of more sophisticated and versatile pneumatic rotary tables. These innovations have enabled manufacturers to offer products that are not only more efficient but also more adaptable to different industrial needs. As industries continue to evolve and seek more advanced technologies, the Global Pneumatic Rotary Table Market is poised to capitalize on these trends, providing new opportunities for businesses to improve their operations and achieve greater efficiency. The market's expansion is also likely to be fueled by the increasing adoption of smart technologies, such as sensors and automation systems, which enhance the performance and functionality of pneumatic rotary tables. These advancements are expected to drive further growth in the market, offering new possibilities for innovation and development. Overall, the Global Pneumatic Rotary Table Market is set to experience significant growth in the coming years, driven by the increasing demand for automation and precision in various industries.

| Report Metric | Details |

| Report Name | Pneumatic Rotary Table Market |

| Accounted market size in 2024 | US$ 413 million |

| Forecasted market size in 2030 | US$ 500 million |

| CAGR | 3.2 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Kitagawa Europe, Unimec SA, ZOLLERN, AUTOMAX, Krautzberger, G.P.A., DECO TECH, Festo Corporation, WEISS North America, Inc, GIMATIC, Airtac |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |