What is Global Piston Check Valves Market?

The Global Piston Check Valves Market is a significant segment within the broader industrial valves industry. Piston check valves are essential components used to control the flow of fluids in various industrial applications. These valves are designed to allow fluid to flow in one direction while preventing backflow, which is crucial for maintaining system integrity and efficiency. The market for piston check valves is driven by the increasing demand for efficient flow control solutions across various industries, including oil and gas, chemicals, power generation, and water treatment. The growth of these industries, particularly in emerging economies, has led to a rise in the adoption of piston check valves. Additionally, technological advancements in valve design and materials have enhanced the performance and durability of these valves, further boosting their market demand. The global market for piston check valves is characterized by a diverse range of products, catering to different industrial needs and specifications. Manufacturers are focusing on developing innovative solutions to meet the evolving requirements of end-users, thereby driving market growth. Overall, the Global Piston Check Valves Market is poised for steady expansion, supported by the ongoing industrialization and infrastructure development worldwide.

in the Global Piston Check Valves Market:

The Global Piston Check Valves Market offers a variety of types to cater to the diverse needs of its customers. These types are primarily differentiated based on their design, material, and application suitability. One of the most common types is the swing check valve, which uses a disc that swings on a hinge or shaft to block reverse flow. This type is widely used due to its simple design and ease of maintenance. Another popular type is the lift check valve, which operates by lifting a disc off its seat to allow flow and dropping it back to prevent reverse flow. Lift check valves are known for their reliability and are often used in high-pressure applications. Piston check valves, specifically, are a subtype of lift check valves where the disc is replaced by a piston. This design provides a more controlled and stable flow, making it suitable for applications requiring precise flow regulation. Dual plate check valves, also known as wafer check valves, are another type that features two spring-loaded plates that open with forward flow and close against reverse flow. These valves are compact and lightweight, making them ideal for space-constrained installations. Ball check valves use a ball to block reverse flow and are commonly used in applications where a tight seal is required. Each type of piston check valve is designed to meet specific operational requirements, and the choice of valve depends on factors such as the nature of the fluid, pressure, temperature, and installation environment. For instance, in the oil and gas industry, where harsh conditions and high pressures are common, robust and corrosion-resistant materials like stainless steel or alloy are preferred. In contrast, for water treatment applications, where the focus is on preventing contamination, materials like PVC or other non-corrosive substances are often used. The versatility of piston check valves in terms of design and material selection makes them suitable for a wide range of applications, ensuring their continued demand across various industries. Manufacturers are continually innovating to enhance the performance and efficiency of these valves, incorporating features such as noise reduction, energy efficiency, and smart monitoring capabilities. As industries evolve and new challenges emerge, the Global Piston Check Valves Market is expected to adapt and grow, offering solutions that meet the changing needs of its customers.

Chemicals, Oil & Gas, Power, Other in the Global Piston Check Valves Market:

The Global Piston Check Valves Market finds extensive usage across several key industries, including chemicals, oil and gas, power generation, and others. In the chemical industry, piston check valves are crucial for ensuring the safe and efficient handling of various chemicals. These valves help prevent backflow, which can lead to contamination or hazardous situations. The ability to withstand corrosive substances and high temperatures makes piston check valves an ideal choice for chemical processing applications. In the oil and gas sector, piston check valves play a vital role in maintaining the integrity of pipelines and processing systems. They are used to prevent the reverse flow of oil, gas, and other fluids, ensuring smooth and uninterrupted operations. The harsh conditions and high pressures typical of this industry require valves that are robust and reliable, and piston check valves meet these demands effectively. In power generation, piston check valves are used in steam and water systems to prevent backflow and ensure efficient energy production. These valves help maintain the stability and safety of power plants by regulating the flow of fluids and preventing potential damage to equipment. Other industries, such as water treatment and pharmaceuticals, also rely on piston check valves for their flow control needs. In water treatment, these valves help prevent contamination and ensure the safe distribution of clean water. In the pharmaceutical industry, where precision and cleanliness are paramount, piston check valves are used to maintain the integrity of fluid handling systems. The versatility and reliability of piston check valves make them indispensable across these diverse applications, contributing to their widespread adoption and market growth. As industries continue to evolve and face new challenges, the demand for efficient and reliable flow control solutions like piston check valves is expected to remain strong.

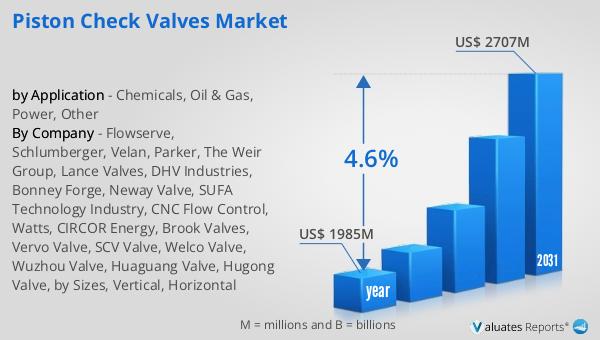

Global Piston Check Valves Market Outlook:

The global market for piston check valves was valued at approximately $1,985 million in 2024. Looking ahead, this market is anticipated to grow significantly, reaching an estimated value of $2,707 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. This steady increase in market size reflects the rising demand for piston check valves across various industries, driven by the need for efficient and reliable flow control solutions. The projected growth is supported by factors such as industrialization, infrastructure development, and technological advancements in valve design and materials. As industries continue to expand and modernize, the demand for high-performance piston check valves is expected to rise, contributing to the market's positive outlook. Manufacturers are likely to focus on innovation and product development to meet the evolving needs of end-users, further driving market growth. Overall, the global piston check valves market is poised for steady expansion, offering opportunities for industry players to capitalize on the growing demand for efficient flow control solutions.

| Report Metric | Details |

| Report Name | Piston Check Valves Market |

| Accounted market size in year | US$ 1985 million |

| Forecasted market size in 2031 | US$ 2707 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Flowserve, Schlumberger, Velan, Parker, The Weir Group, Lance Valves, DHV Industries, Bonney Forge, Neway Valve, SUFA Technology Industry, CNC Flow Control, Watts, CIRCOR Energy, Brook Valves, Vervo Valve, SCV Valve, Welco Valve, Wuzhou Valve, Huaguang Valve, Hugong Valve, by Sizes, Vertical, Horizontal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |