What is Global Phenolic Resin Conductive Adhesive Market?

The Global Phenolic Resin Conductive Adhesive Market is a specialized segment within the broader adhesive industry, focusing on the use of phenolic resin as a key component in conductive adhesives. Phenolic resins are synthetic polymers obtained by the reaction of phenol with formaldehyde, known for their high mechanical strength, thermal stability, and resistance to chemicals. These properties make them ideal for use in conductive adhesives, which are essential in various electronic applications. Conductive adhesives are used to create electrical connections between components, offering an alternative to traditional soldering methods. The global market for these adhesives is driven by the increasing demand for miniaturized and more efficient electronic devices, as well as the growing trend towards environmentally friendly and lead-free manufacturing processes. The market is characterized by continuous innovation and development, with manufacturers focusing on enhancing the performance characteristics of phenolic resin conductive adhesives to meet the evolving needs of industries such as electronics, automotive, and renewable energy. As technology advances, the demand for these specialized adhesives is expected to grow, driven by their critical role in ensuring the reliability and performance of electronic devices.

Curing Reaction Type, Hot Melt, High Temperature Sintering in the Global Phenolic Resin Conductive Adhesive Market:

The curing reaction type, hot melt, and high-temperature sintering are crucial processes in the Global Phenolic Resin Conductive Adhesive Market, each offering unique benefits and applications. The curing reaction type involves a chemical process where the adhesive undergoes a transformation from a liquid or semi-liquid state to a solid state, forming a strong bond between surfaces. This process is essential for ensuring the durability and reliability of the adhesive in various applications. Curing can be achieved through different methods, including thermal curing, where heat is applied to accelerate the reaction, or through UV curing, which uses ultraviolet light to initiate the process. The choice of curing method depends on the specific requirements of the application, such as the desired bond strength, curing time, and environmental conditions. Hot melt adhesives, on the other hand, are thermoplastic materials that become liquid upon heating and solidify upon cooling. They offer several advantages, including fast setting times, ease of application, and the ability to bond a wide range of materials. Hot melt adhesives are particularly useful in applications where speed and efficiency are critical, such as in high-volume manufacturing processes. High-temperature sintering is a process that involves heating the adhesive to a temperature below its melting point, causing the particles to fuse together and form a solid mass. This method is often used in applications where high thermal stability and mechanical strength are required, such as in the automotive and aerospace industries. Each of these processes plays a vital role in the performance and application of phenolic resin conductive adhesives, allowing manufacturers to tailor their products to meet the specific needs of different industries. By understanding the unique characteristics and benefits of each process, manufacturers can optimize the performance of their adhesives and expand their applications in the global market.

Cameras, Displays, Photovoltaics, LEDs and OLEDs in the Global Phenolic Resin Conductive Adhesive Market:

The Global Phenolic Resin Conductive Adhesive Market finds extensive usage in various high-tech applications, including cameras, displays, photovoltaics, LEDs, and OLEDs. In the realm of cameras, these adhesives are crucial for ensuring reliable electrical connections between components, such as sensors and circuit boards. The miniaturization of camera components demands adhesives that can provide strong bonds while maintaining electrical conductivity, making phenolic resin conductive adhesives an ideal choice. In displays, these adhesives are used to connect flexible circuits and other components, ensuring seamless electrical connections that are essential for the functionality of modern screens. The demand for thinner and more flexible displays has driven the need for adhesives that can maintain performance under bending and flexing conditions. In the field of photovoltaics, phenolic resin conductive adhesives are used to connect solar cells and other components, playing a critical role in the efficiency and reliability of solar panels. These adhesives must withstand harsh environmental conditions, such as temperature fluctuations and UV exposure, while maintaining their conductive properties. In the lighting industry, LEDs and OLEDs rely on conductive adhesives for electrical connections between components, ensuring efficient energy transfer and long-lasting performance. The unique properties of phenolic resin conductive adhesives, such as thermal stability and chemical resistance, make them well-suited for these applications, where reliability and performance are paramount. As technology continues to advance, the demand for phenolic resin conductive adhesives in these areas is expected to grow, driven by the need for more efficient, reliable, and environmentally friendly solutions.

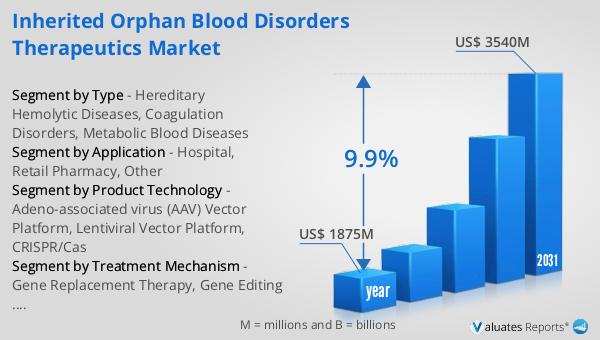

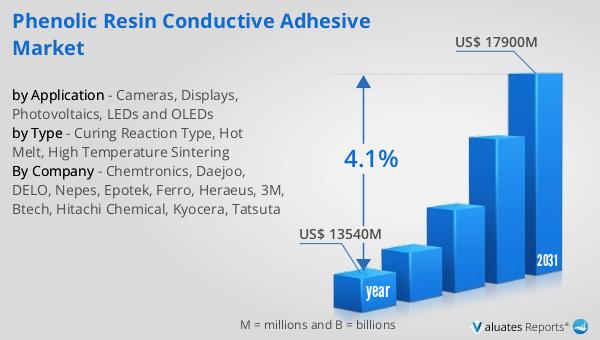

Global Phenolic Resin Conductive Adhesive Market Outlook:

The global market for Phenolic Resin Conductive Adhesive was valued at approximately $13.54 billion in 2024 and is anticipated to expand to a revised size of around $17.9 billion by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.1% over the forecast period. This steady increase underscores the rising demand for phenolic resin conductive adhesives across various industries, driven by the need for advanced materials that offer superior performance and environmental benefits. The market's expansion is fueled by the growing adoption of these adhesives in electronics, automotive, and renewable energy sectors, where they play a critical role in ensuring the reliability and efficiency of products. As industries continue to innovate and seek sustainable solutions, the demand for phenolic resin conductive adhesives is expected to rise, contributing to the market's growth. The projected increase in market size highlights the importance of these adhesives in modern manufacturing processes and their potential to drive advancements in technology and sustainability. With a focus on enhancing performance characteristics and meeting the evolving needs of various industries, the Global Phenolic Resin Conductive Adhesive Market is poised for continued growth and development in the coming years.

| Report Metric | Details |

| Report Name | Phenolic Resin Conductive Adhesive Market |

| Accounted market size in year | US$ 13540 million |

| Forecasted market size in 2031 | US$ 17900 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Chemtronics, Daejoo, DELO, Nepes, Epotek, Ferro, Heraeus, 3M, Btech, Hitachi Chemical, Kyocera, Tatsuta |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |