What is Global Pharmaceutical Manufacturing Software Market?

The Global Pharmaceutical Manufacturing Software Market is a specialized segment within the broader pharmaceutical industry that focuses on the development and implementation of software solutions tailored to the unique needs of pharmaceutical manufacturing. This market encompasses a wide range of software applications designed to streamline and optimize various aspects of pharmaceutical production, including research and development, quality control, regulatory compliance, supply chain management, and production scheduling. These software solutions are crucial for ensuring that pharmaceutical products are manufactured efficiently, safely, and in compliance with stringent industry regulations. By leveraging advanced technologies such as artificial intelligence, machine learning, and data analytics, pharmaceutical manufacturing software helps companies enhance productivity, reduce operational costs, and improve product quality. The market is driven by the increasing demand for innovative and efficient pharmaceutical products, the need for stringent regulatory compliance, and the growing adoption of digital technologies in the pharmaceutical industry. As pharmaceutical companies strive to meet the ever-evolving demands of the global healthcare market, the role of manufacturing software becomes increasingly vital in ensuring that they can deliver high-quality products in a timely and cost-effective manner.

On Cloud, On Premise in the Global Pharmaceutical Manufacturing Software Market:

In the Global Pharmaceutical Manufacturing Software Market, two primary deployment models are prevalent: On Cloud and On Premise. Each model offers distinct advantages and challenges, catering to different organizational needs and preferences. On Cloud deployment refers to software solutions hosted on remote servers and accessed via the internet. This model offers several benefits, including scalability, flexibility, and cost-effectiveness. Pharmaceutical companies can easily scale their operations up or down based on demand without the need for significant upfront investments in hardware or infrastructure. Additionally, cloud-based solutions facilitate seamless collaboration and data sharing across geographically dispersed teams, enhancing productivity and innovation. The cloud model also ensures automatic software updates and maintenance, reducing the burden on internal IT teams. However, concerns about data security and compliance with industry regulations can pose challenges for some organizations considering cloud deployment. On the other hand, On Premise deployment involves installing software solutions directly on a company's local servers and infrastructure. This model provides greater control over data security and compliance, as organizations can implement their own security protocols and ensure that sensitive information remains within their premises. On Premise solutions are often preferred by large enterprises with substantial IT resources and stringent regulatory requirements. However, this model requires significant upfront investments in hardware and ongoing maintenance costs, which can be a barrier for smaller organizations. Additionally, On Premise solutions may lack the flexibility and scalability offered by cloud-based alternatives, making it challenging for companies to adapt to changing market conditions. Despite these challenges, some pharmaceutical companies opt for a hybrid approach, combining the benefits of both On Cloud and On Premise models to create a tailored solution that meets their specific needs. This approach allows organizations to leverage the scalability and flexibility of the cloud while maintaining control over critical data and processes. Ultimately, the choice between On Cloud and On Premise deployment depends on various factors, including organizational size, budget, regulatory requirements, and strategic goals. As the pharmaceutical industry continues to evolve, companies must carefully evaluate their options and select the deployment model that best aligns with their operational needs and long-term objectives.

Large Enterprises, SMEs in the Global Pharmaceutical Manufacturing Software Market:

The usage of Global Pharmaceutical Manufacturing Software Market solutions varies significantly between large enterprises and small to medium-sized enterprises (SMEs), reflecting their distinct operational needs and resource capabilities. Large enterprises, with their extensive resources and complex operations, often require comprehensive software solutions that can integrate seamlessly across multiple departments and locations. These organizations benefit from advanced features such as predictive analytics, real-time monitoring, and automated reporting, which enable them to optimize production processes, enhance quality control, and ensure compliance with stringent regulatory standards. Large enterprises typically have the financial capacity to invest in robust On Premise solutions, providing them with greater control over data security and customization. However, many are also embracing cloud-based solutions to leverage their scalability and flexibility, allowing them to respond swiftly to market changes and global demands. In contrast, SMEs often face budget constraints and may lack the extensive IT infrastructure of larger organizations. As a result, they tend to favor cloud-based solutions, which offer a cost-effective and scalable alternative to traditional On Premise systems. Cloud-based software allows SMEs to access advanced manufacturing capabilities without the need for significant upfront investments, enabling them to compete more effectively in the market. These solutions also facilitate collaboration and data sharing, helping SMEs streamline their operations and improve efficiency. Despite their smaller size, SMEs are increasingly recognizing the importance of digital transformation and are investing in software solutions to enhance their competitiveness and meet regulatory requirements. Both large enterprises and SMEs face unique challenges and opportunities in the pharmaceutical manufacturing sector, and the choice of software solutions plays a critical role in determining their success. By selecting the right software and deployment model, organizations can optimize their operations, reduce costs, and deliver high-quality pharmaceutical products to the market.

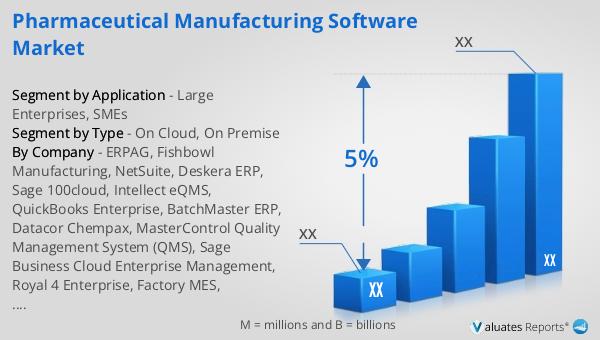

Global Pharmaceutical Manufacturing Software Market Outlook:

The outlook for the Global Pharmaceutical Manufacturing Software Market is closely tied to the broader trends in the pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with a projected compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products and the need for efficient manufacturing processes to meet this demand. In comparison, the chemical drug market experienced growth from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth trajectory highlights the expanding role of pharmaceutical manufacturing software in supporting the production of chemical drugs and other pharmaceutical products. As the industry continues to evolve, companies are increasingly turning to advanced software solutions to enhance their manufacturing capabilities, improve product quality, and ensure compliance with regulatory standards. The adoption of digital technologies, such as artificial intelligence and machine learning, is expected to further drive the growth of the pharmaceutical manufacturing software market, enabling companies to optimize their operations and deliver innovative products to the market. As a result, the demand for specialized software solutions is likely to increase, providing significant opportunities for software providers and pharmaceutical companies alike.

| Report Metric | Details |

| Report Name | Pharmaceutical Manufacturing Software Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ERPAG, Fishbowl Manufacturing, NetSuite, Deskera ERP, Sage 100cloud, Intellect eQMS, QuickBooks Enterprise, BatchMaster ERP, Datacor Chempax, MasterControl Quality Management System (QMS), Sage Business Cloud Enterprise Management, Royal 4 Enterprise, Factory MES, Columbus Manufacturing, Prodsmart, Process Force, S2K Manufacturing Management Software, Aquilon ERP, MRPeasy |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |