What is Global Pharmaceutical Capsule Filling Machines Market?

The Global Pharmaceutical Capsule Filling Machines Market is a crucial segment within the pharmaceutical manufacturing industry. These machines are designed to fill empty capsules with pharmaceutical powders, granules, or liquids, ensuring precise dosage and consistency. The market is driven by the increasing demand for efficient and high-speed capsule filling solutions, as pharmaceutical companies strive to meet the growing needs of healthcare systems worldwide. Technological advancements have led to the development of machines that offer enhanced accuracy, speed, and flexibility, catering to various capsule sizes and formulations. The market is characterized by a diverse range of machines, from fully automatic to semi-automatic models, each catering to different production scales and requirements. As the pharmaceutical industry continues to expand, driven by factors such as an aging population and the rise of chronic diseases, the demand for capsule filling machines is expected to grow, making it a vital component of the global pharmaceutical supply chain.

Fully Automatic, Semi-Automatic in the Global Pharmaceutical Capsule Filling Machines Market:

Fully automatic and semi-automatic capsule filling machines play a pivotal role in the Global Pharmaceutical Capsule Filling Machines Market, each offering distinct advantages and catering to different production needs. Fully automatic capsule filling machines are designed for high-volume production environments, where speed and efficiency are paramount. These machines can fill thousands of capsules per hour, significantly reducing labor costs and minimizing human error. They are equipped with advanced features such as touch-screen interfaces, automated cleaning systems, and precise dosing mechanisms, ensuring consistent product quality and compliance with stringent regulatory standards. The automation of the filling process not only enhances productivity but also allows for the seamless integration of quality control measures, such as weight checks and defect detection, ensuring that only capsules meeting the required specifications are packaged and distributed. On the other hand, semi-automatic capsule filling machines offer a more flexible and cost-effective solution for smaller-scale production or research and development settings. These machines require some level of manual intervention, such as loading empty capsules and monitoring the filling process, but they provide greater control over the production parameters. Semi-automatic machines are ideal for companies that produce a wide variety of products in smaller batches, as they allow for quick changeovers between different capsule sizes and formulations. They are also favored by companies that prioritize customization and experimentation, as operators can easily adjust the filling parameters to accommodate unique product characteristics. Despite their lower throughput compared to fully automatic machines, semi-automatic models offer a balance between efficiency and adaptability, making them a popular choice for many pharmaceutical manufacturers. Both fully automatic and semi-automatic capsule filling machines are integral to the pharmaceutical manufacturing process, enabling companies to produce high-quality products that meet the demands of the global healthcare market. As technology continues to evolve, these machines are expected to become even more sophisticated, offering enhanced capabilities and further driving the growth of the Global Pharmaceutical Capsule Filling Machines Market.

Pharmaceutical Factory, Medical Company, Other in the Global Pharmaceutical Capsule Filling Machines Market:

The usage of Global Pharmaceutical Capsule Filling Machines Market extends across various sectors, including pharmaceutical factories, medical companies, and other related industries. In pharmaceutical factories, these machines are essential for large-scale production of capsules, which are a popular dosage form due to their ease of administration and ability to mask unpleasant tastes. Capsule filling machines in these settings are often fully automated, allowing for high-speed production and ensuring that the capsules meet strict quality standards. The ability to produce large quantities of capsules efficiently is crucial for pharmaceutical factories, as it enables them to meet the demands of healthcare providers and patients worldwide. In medical companies, capsule filling machines are used for both commercial production and research and development purposes. These companies often require machines that offer flexibility and precision, as they may be involved in the development of new drugs or the production of specialized formulations. Semi-automatic machines are particularly valuable in these settings, as they allow for greater control over the filling process and can be easily adjusted to accommodate different capsule sizes and formulations. This flexibility is essential for medical companies that need to produce small batches of experimental drugs or customized formulations for clinical trials. Beyond pharmaceutical factories and medical companies, capsule filling machines are also used in other industries, such as nutraceuticals and veterinary medicine. In the nutraceutical industry, these machines are used to produce dietary supplements in capsule form, which are popular among consumers seeking convenient and effective ways to improve their health. Similarly, in veterinary medicine, capsule filling machines are used to produce medications for animals, ensuring accurate dosing and ease of administration. The versatility of capsule filling machines makes them a valuable asset across various sectors, enabling companies to produce high-quality products that meet the diverse needs of their customers. As the demand for capsules continues to grow, driven by factors such as an aging population and increasing health awareness, the Global Pharmaceutical Capsule Filling Machines Market is expected to expand, further solidifying its importance in the global healthcare landscape.

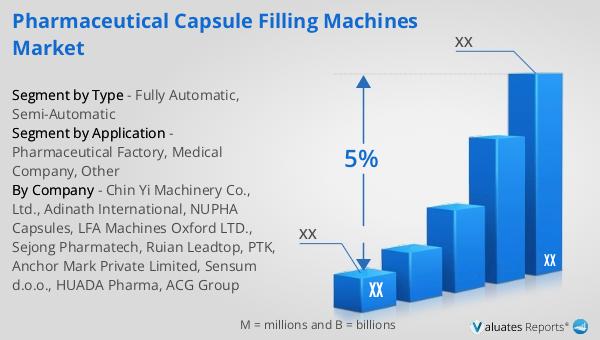

Global Pharmaceutical Capsule Filling Machines Market Outlook:

The outlook for the Global Pharmaceutical Capsule Filling Machines Market is closely tied to the broader trends in the pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with a projected compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products, driven by factors such as an aging population, the rise of chronic diseases, and advancements in medical technology. In comparison, the chemical drug market, a significant segment of the pharmaceutical industry, was estimated to grow from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This steady growth highlights the ongoing need for efficient and reliable manufacturing solutions, such as capsule filling machines, to meet the rising demand for pharmaceutical products. As pharmaceutical companies continue to expand their production capabilities to cater to the growing global healthcare needs, the demand for advanced capsule filling machines is expected to increase. These machines play a crucial role in ensuring the efficient and accurate production of capsules, which are a preferred dosage form for many medications due to their ease of administration and ability to deliver precise dosages. The Global Pharmaceutical Capsule Filling Machines Market is poised to benefit from these industry trends, as companies invest in state-of-the-art equipment to enhance their manufacturing processes and maintain a competitive edge in the market.

| Report Metric | Details |

| Report Name | Pharmaceutical Capsule Filling Machines Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Chin Yi Machinery Co., Ltd., Adinath International, NUPHA Capsules, LFA Machines Oxford LTD., Sejong Pharmatech, Ruian Leadtop, PTK, Anchor Mark Private Limited, Sensum d.o.o., HUADA Pharma, ACG Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |