What is Global Paper Tape Filter Market?

The Global Paper Tape Filter Market is a specialized segment within the broader filtration industry, focusing on the use of paper tape filters for various applications. These filters are designed to remove impurities from liquids, making them essential in industries where maintaining the purity of fluids is crucial. The market encompasses a range of products that vary in size, capacity, and application, catering to diverse industrial needs. Paper tape filters are particularly valued for their efficiency, cost-effectiveness, and ease of use. They are commonly used in sectors such as automotive, aerospace, and manufacturing, where they help in maintaining the quality of coolants, oils, and other fluids. The market is driven by the increasing demand for high-quality filtration systems that can enhance operational efficiency and reduce maintenance costs. As industries continue to prioritize sustainability and environmental responsibility, the adoption of paper tape filters is expected to rise, further propelling market growth. The market is characterized by technological advancements and innovations aimed at improving filter performance and extending their lifespan. Overall, the Global Paper Tape Filter Market plays a vital role in ensuring the smooth operation of various industrial processes by providing reliable and effective filtration solutions.

Gravity Type Paper Belt Filter, Forced Type Paper Tape Filter in the Global Paper Tape Filter Market:

The Gravity Type Paper Belt Filter and Forced Type Paper Tape Filter are two prominent technologies within the Global Paper Tape Filter Market, each offering unique advantages and applications. The Gravity Type Paper Belt Filter operates on the principle of gravity to facilitate the filtration process. It is designed with a continuous belt of filter paper that moves over a series of rollers. As the liquid containing impurities flows over the filter paper, gravity pulls the liquid through the paper, leaving the solid impurities on the surface. This type of filter is particularly effective for applications where the liquid has a low viscosity and the impurities are relatively large. It is commonly used in industries such as metalworking and machining, where it helps in removing metal shavings and other debris from coolants and lubricants. The simplicity of its design makes it easy to operate and maintain, while its continuous operation ensures a steady flow of filtered liquid. On the other hand, the Forced Type Paper Tape Filter employs a more active approach to filtration. It uses a pump or other mechanical means to force the liquid through the filter paper, enhancing the filtration efficiency and speed. This type of filter is ideal for applications where the liquid has a higher viscosity or the impurities are finer and more challenging to remove. It is often used in industries such as chemical processing and food and beverage production, where maintaining the purity of liquids is critical. The Forced Type Paper Tape Filter is known for its high filtration accuracy and ability to handle a wide range of impurities. Both types of filters are integral to the Global Paper Tape Filter Market, offering solutions that cater to different industrial needs and challenges. As industries continue to evolve and demand more efficient filtration systems, these technologies are expected to play a crucial role in meeting those needs. The choice between a Gravity Type Paper Belt Filter and a Forced Type Paper Tape Filter often depends on the specific requirements of the application, including the nature of the liquid, the type of impurities, and the desired level of filtration. By understanding the strengths and limitations of each type, industries can make informed decisions that optimize their filtration processes and enhance overall operational efficiency.

Metal Impurity Filtration, Non-metallic Impurity Filtration in the Global Paper Tape Filter Market:

The Global Paper Tape Filter Market finds significant usage in the filtration of both metal and non-metallic impurities, addressing the diverse needs of various industries. In the realm of metal impurity filtration, paper tape filters are indispensable tools for maintaining the quality and performance of industrial fluids. Metalworking industries, for instance, rely heavily on these filters to remove metal shavings, chips, and other debris from coolants and lubricants. This not only ensures the longevity and efficiency of the machinery but also enhances the quality of the finished products. The ability of paper tape filters to effectively capture and remove metal impurities helps in reducing wear and tear on equipment, minimizing downtime, and lowering maintenance costs. Additionally, these filters contribute to environmental sustainability by enabling the recycling and reuse of industrial fluids, thereby reducing waste and conserving resources. In the context of non-metallic impurity filtration, paper tape filters are equally valuable. Industries such as food and beverage, pharmaceuticals, and chemical processing require high levels of purity in their liquids to ensure product safety and quality. Paper tape filters are adept at removing non-metallic impurities such as dust, fibers, and other particulates that can compromise the integrity of the final product. Their ability to provide consistent and reliable filtration makes them a preferred choice for applications where precision and cleanliness are paramount. Moreover, the versatility of paper tape filters allows them to be customized to meet the specific needs of different industries, ensuring optimal performance and efficiency. As the demand for high-quality filtration solutions continues to grow, the Global Paper Tape Filter Market is poised to play a crucial role in supporting industries in their quest for cleaner and more sustainable operations. By offering effective solutions for both metal and non-metallic impurity filtration, paper tape filters help industries achieve their operational goals while adhering to stringent quality and environmental standards.

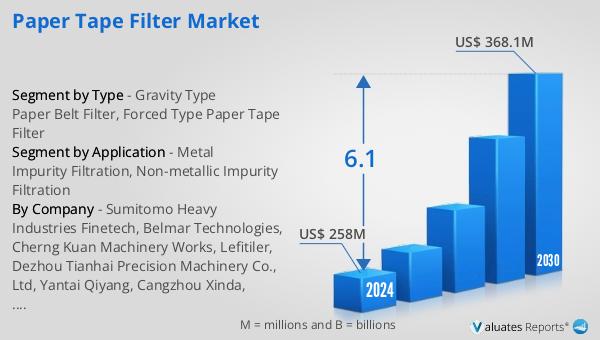

Global Paper Tape Filter Market Outlook:

The outlook for the Global Paper Tape Filter Market indicates a promising growth trajectory over the coming years. According to projections, the market is expected to expand from a valuation of US$ 258 million in 2024 to approximately US$ 368.1 million by 2030. This growth represents a Compound Annual Growth Rate (CAGR) of 6.1% during the forecast period. Such a positive outlook can be attributed to several factors driving the demand for paper tape filters across various industries. The increasing emphasis on operational efficiency and cost-effectiveness is prompting industries to adopt advanced filtration solutions that can enhance the performance and longevity of their equipment. Additionally, the growing awareness of environmental sustainability and the need to reduce waste is encouraging industries to invest in filtration systems that enable the recycling and reuse of industrial fluids. Technological advancements and innovations in filter design and materials are also contributing to the market's growth by offering improved filtration efficiency and durability. As industries continue to evolve and face new challenges, the demand for reliable and effective filtration solutions is expected to rise, further fueling the growth of the Global Paper Tape Filter Market. This positive market outlook underscores the importance of paper tape filters in supporting industries in their pursuit of cleaner, more efficient, and sustainable operations.

| Report Metric | Details |

| Report Name | Paper Tape Filter Market |

| Accounted market size in 2024 | US$ 258 million |

| Forecasted market size in 2030 | US$ 368.1 million |

| CAGR | 6.1 |

| Base Year | 2024 |

| Forecasted years | 2025 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Sumitomo Heavy Industries Finetech, Belmar Technologies, Cherng Kuan Machinery Works, Lefitiler, Dezhou Tianhai Precision Machinery Co., Ltd, Yantai Qiyang, Cangzhou Xinda, Yantai Lifeng, Shanghai Huiqi, Shandong Zhongde, Yantai Yixin Xiangyu, Wuxi Jiangshan Machinery, Yantai Taifeng Machinery, Yantai EGR |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |